As a kind of screening equipment widely used in the industrial field, the dewatering screen plays a pivotal role in many industries such as mining, coal, metallurgy, and building materials with its ability to efficiently screen and significantly improve material quality. The following is a detailed decryption of the dewatering screen:

1. Working principle of dewatering screen

The working principle of dewatering the screen is mainly based on vibrating screening technology. When the motor starts, the excitation force generated by the vibrator causes the screen body to make a reciprocating linear motion in the horizontal direction. After the material enters the screen surface from the feed port, under the action of the vibration of the screen surface, the material particles smaller than the screen hole are discharged through the screen hole, while the material larger than the screen hole continues to be screened on the screen surface. At the same time, due to the vibration of the screen surface, the moisture and mud in the material are effectively separated, thereby achieving dehydration, desliming, and classification of the material.

2. Dewatering screen structure design

The structure of the dehydration screen is exquisitely designed, mainly including the screen body, vibration exciter, vibration reduction device, screen mesh, and other parts. The screen body is usually welded with high-strength steel plates and has sufficient rigidity and stability. The vibrator is the core component of the dewatering screen, and its performance directly affects the screening effect. The vibration reduction device is used to reduce the impact of screen vibration on the surrounding environment and equipment. As the screening surface of the dehydration screen, the screen material, aperture, weaving method, and other factors will directly affect the screening efficiency and screening accuracy.

3. High-efficiency screening capacity of dewatering screen

Dewatering screens are known for their efficient screening capabilities. It has a large screen area and strong processing capacity and can handle a large amount of materials at one time. At the same time, the internal structure design is reasonable, the material flows on the screen surface more smoothly, and the screening efficiency is effectively improved. This high-efficiency screening capability not only ensures the continuous and stable operation of the production line but also greatly improves production efficiency.

4. Dehydration screen improves material quality

The dewatering screen can significantly improve the quality of materials through its unique screening and dewatering functions. In the mining industry, dewatering screens are often used to screen materials such as ore and coal gangue to improve the quality and utilization of materials; in the coal industry, dewatering screens are used to screen coal, coal slime, and other materials to reduce moisture and ash content. , improve the calorific value and combustion efficiency of coal; in the building materials industry, dewatering screens are often used to screen sand, limestone, and other materials to improve the uniformity and quality of the materials. These improvements make the dewatering screenplay an irreplaceable role in improving material quality.

5. Advantages and application prospects of dehydration screen

The dehydration screen has the advantages of high screening efficiency, good dehydration effect, wide application range, and simple structure. With the continuous development of industrial production, the application prospects of dewatering screens will be broader. In the future, dewatering screens will continue to face new challenges and opportunities and will further meet market needs and customer expectations through technological innovation and product upgrades.

Dewatering screens play an important role in many industries with their ability to efficiently screen and significantly improve material quality. With the continuous advancement of technology and the continuous development of industrial production, dewatering screens will surely show their unique charm and value in more fields.

Service Guarantee

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

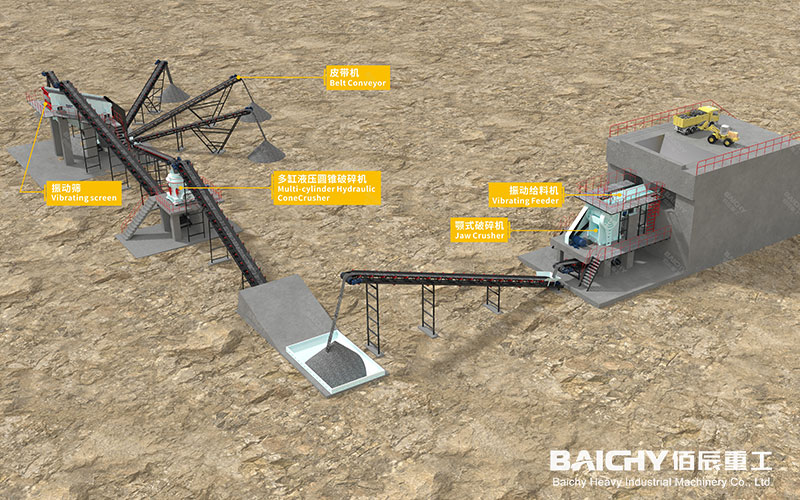

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.