High-pressure coal mill vertical mill, also known as a roller mill or vertical coal mill, is a key piece of equipment in the coal pulverizing system, mainly used to grind raw coal into pulverized coal and dry it. The following is a detailed introduction to a high-pressure coal mill vertical mill:

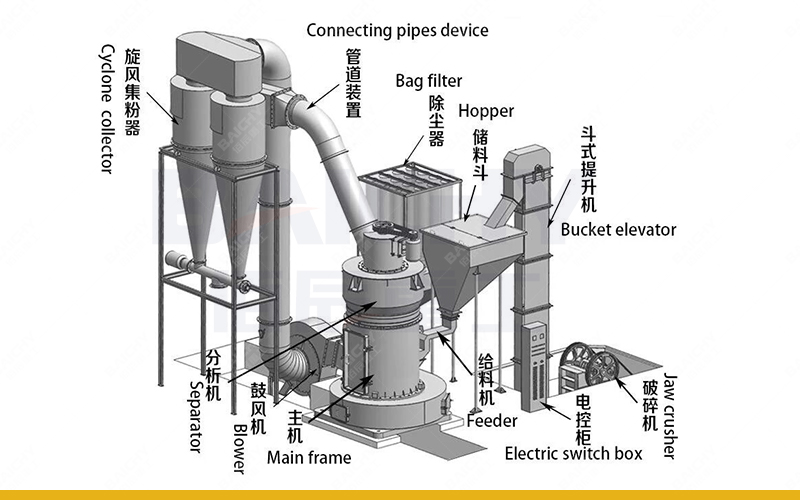

Basic components of high-pressure coal mill vertical mill

• Foundation: Supports the weight of the entire coal mill.

• Reducer: Drives the coal mill disc to rotate through the planetary reducer.

• Lower frame machine, middle frame machine: constitute the main frame of the coal mill.

• Grinding disc: Raw coal is distributed on it, and centrifugal force is generated by rotation.

• Grinding roller: Driven by the grinding disc, it rotates and applies pressure to the raw coal for crushing and grinding.

• Pressurizing device: Usually the hydraulic system drives the spring device to generate grinding force so that sufficient pressure is generated between the grinding roller and the grinding disc.

• Separator: Used to separate qualified coal powder and unqualified coarse coal powder.

Positive pressure air sealing device, and steam purge device: Ensure the sealing and cleanliness of the coal mill.

• Main motor: Provide power.

• Lubricating oil station, hydraulic station: provide lubrication and hydraulic power for reducer, pressure device, etc.

• Sealed fan: maintain the air pressure balance inside the coal mill.

Working principle of high-pressure coal mill vertical mill

The working principle of a high-pressure coal mill vertical mill is mainly based on the principle of material layer extrusion and crushing. The specific process is as follows:

• Feeding: The raw coal enters the coal mill through the coal drop pipe and accumulates in the middle of the rotating grinding disc.

• Grinding: Under the action of the hydraulic system, the grinding roller applies pressure to the material in the grinding disc, and crushes the large particles of raw coal into fine powder through extrusion and grinding. At the same time, the centrifugal force generated by the grinding disc causes the material to move to the periphery of the grinding disc and enter the roller between the grinding roller and the grinding disc.

• Drying: The hot air flow from the wind ring dries the material containing a certain amount of moisture so that the moisture in the material evaporates.

• Separation: The dried powdered material is carried by the airflow to the separator at the top of the mill for sorting. The qualified fine powder is carried out of the machine with the airflow and enters the coal powder bin; unqualified coarse coal powder is returned to the mill for re-grinding.

Advantages and features of high-pressure coal mill

• Large production capacity and low energy consumption: The vertical coal mill adopts the principle of material layer extrusion and crushing, with high grinding efficiency and relatively low energy consumption.

• Green and environmentally friendly: During the grinding process, hot air is not only used to dry the material but also to take away the ground coal powder to reduce dust pollution.

• Safe and reliable: The equipment is equipped with explosion-proof devices and iron protection devices to ensure safe operation under abnormal conditions.

• Easy maintenance: Wearing parts such as grinding rollers and grinding discs are easy to replace and maintain, reducing maintenance costs.

In summary, the high-pressure coal mill is an efficient, energy-saving, and environmentally friendly coal pulverizing equipment, which is widely used in power, chemical, metallurgical, and other industries.

Service Guarantee

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.