Jaw crusher and impact crusher are both important equipment in crushing machinery, but they have significant differences in structure, working principle, application field, and performance characteristics; these differences have their own advantages, and users can choose the appropriate crushing equipment according to their needs and crushed materials.

Let's take you to understand the differences between a jaw crusher and an impact crusher!

1. Different structures and working principles

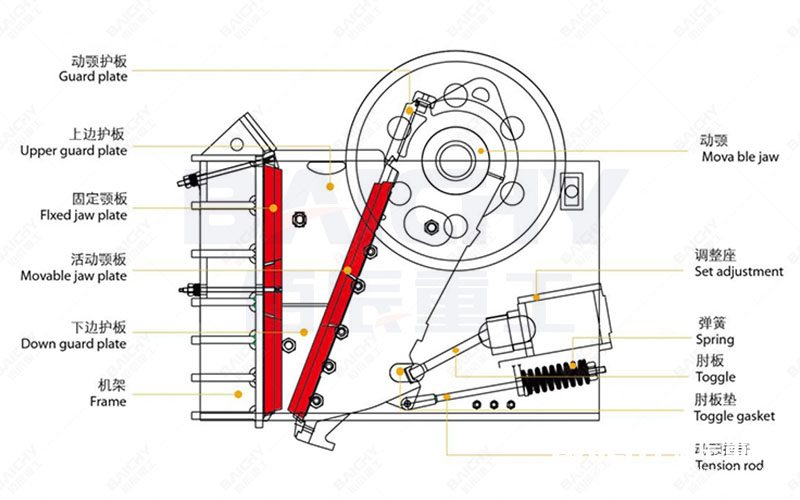

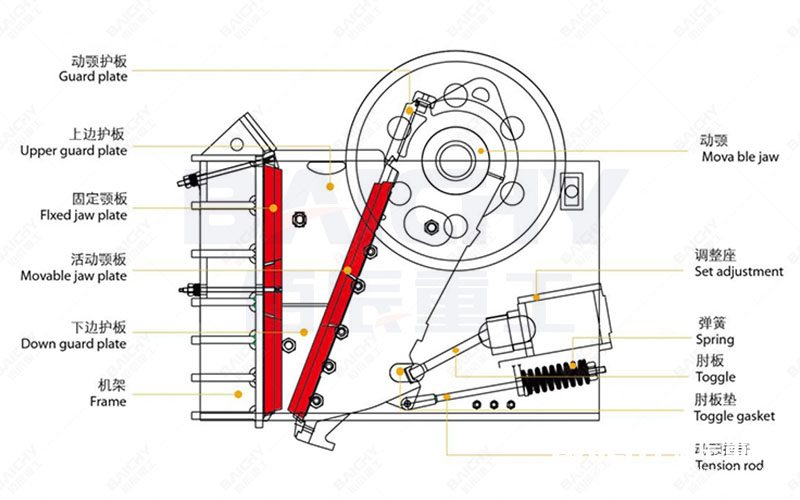

The jaw crusher consists of two jaw plates, the movable jaw, and the static jaw, to form a crushing chamber, simulating the movement of the two jaws of an animal to complete the material crushing operation; the movable jaw plate makes a periodic reciprocating motion on the fixed jaw plate, sometimes approaching and sometimes leaving. When approaching, the material is squeezed, split, and impacted between the two jaw plates and crushed; when leaving, the crushed material is discharged from the discharge port by gravity.

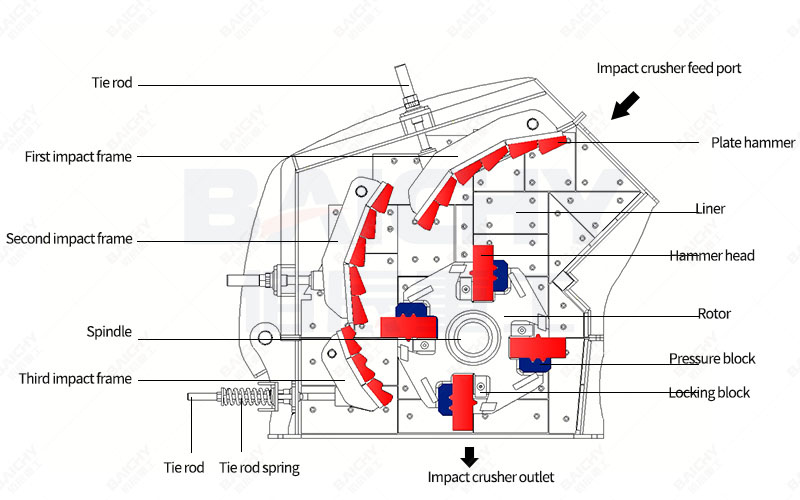

The impact crusher is mainly composed of a rotor (plate hammer), an impact plate, a frame, and other parts; the impact energy is used to crush the material, and the material is repeatedly impacted and crushed between the rotor (plate hammer) and the impact plate.

2. Different application fields

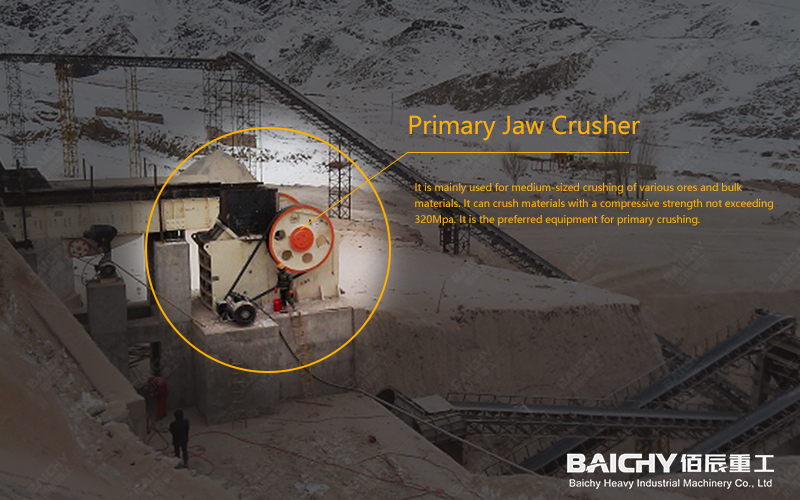

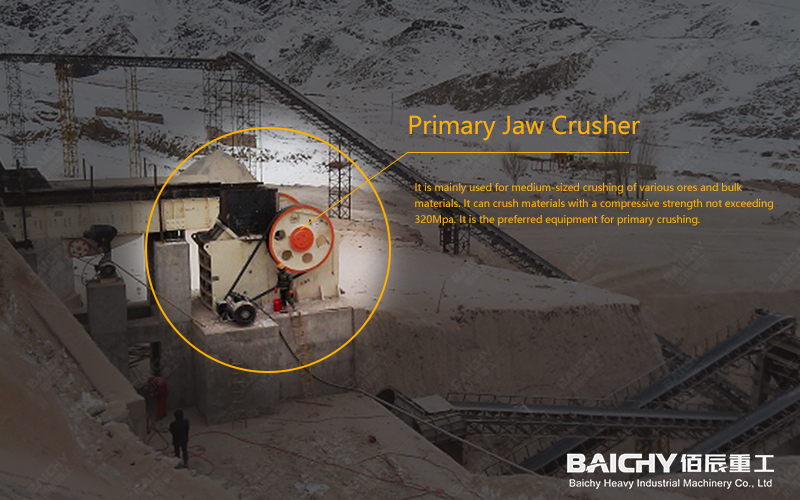

Jaw crusher: widely used in the crushing of various ores and bulk materials in industries such as mining and smelting, building materials, roads, railways, water conservancy, and chemical industry. The maximum compressive strength of the crushed material is 320Mpa, and it is often used as a coarse crusher and a medium crusher.

Impact crusher: mainly used for the processing of materials that often need to be relocated in metallurgy, chemical industry, building materials, hydropower, etc., especially for the operation of mobile stones such as highways, railways, and hydropower projects. It can handle materials with a side length of less than 100-500 mm, and the maximum compressive strength can reach 350 MPa.

3. Different performance characteristics

Jaw crusher

1. Low noise, less dust: conducive to environmental protection and improvement of the working environment.

2. Large crushing ratio, uniform product particle size: suitable for a variety of crushing needs.

3. Simple structure, reliable operation: low operating costs, simple maintenance.

4. Deep crushing chamber and no dead zone: improved feeding capacity and output.

5. Equipment energy saving: single machine energy saving 15% to 30%, system energy saving more than doubled.

6. The adjustment range of the discharge port is large: it can meet the requirements of different users.

Impact crusher

1. The feed port is large and the crushing chamber is high: it is suitable for materials with high hardness, large crushing, and less stone powder in the product.

2. The gap between the impact plate and the hammer is easy to adjust: the discharge particle size can be effectively controlled, and the particle shape is good.

3. Compact structure, strong machine rigidity: the rotor has a large moment of inertia, and is impact-resistant and wear-resistant.

4. The finished product is a cube, without tension and cracks: the particle shape is good, and it is widely used in ore crushing, railways, highways, energy, cement, chemicals, construction, and other industries.

4. Other differences

• Material hardness adaptability: jaw crushers can crush various hard materials, while impact crushers are more suitable for limestone, lime, and other hard and below-low toughness and brittle materials.

• Feed particle size: jaw crushers are generally used to crush large materials, and the allowable feed particle size is larger; impact crushers are mainly used to process some small and medium-sized materials, and the allowable feed particle size range is narrower.

• Production capacity: Generally speaking, the production capacity of jaw crushers is greater than that of impact crushers. The specific output depends on the equipment model and manufacturer.

• Discharge fineness: The jaw crusher is coarse crushing, and the discharge fineness is large; impact crusher is used as intermediate crushing or fine crushing, and the discharge fineness is smaller.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.