When choosing a limestone crusher, an efficient limestone crushing plant needs to comprehensively consider multiple factors such as the crushing efficiency, stability, durability, and production cost of the equipment. The following are some limestone crushers suitable for efficient limestone crushing plants and their characteristics:

Common limestone crusher types and characteristics

Jaw crusher

Features: Jaw crusher is widely used in limestone crushing due to its simple structure, reliable operation, large crushing ratio, and convenient maintenance. It mainly crushes materials through the periodic reciprocating motion of the movable jaw and the static jaw, and is suitable for coarse and medium crushing operations.

Advantages: High crushing efficiency, large processing capacity, and can cope with limestone of various hardness.

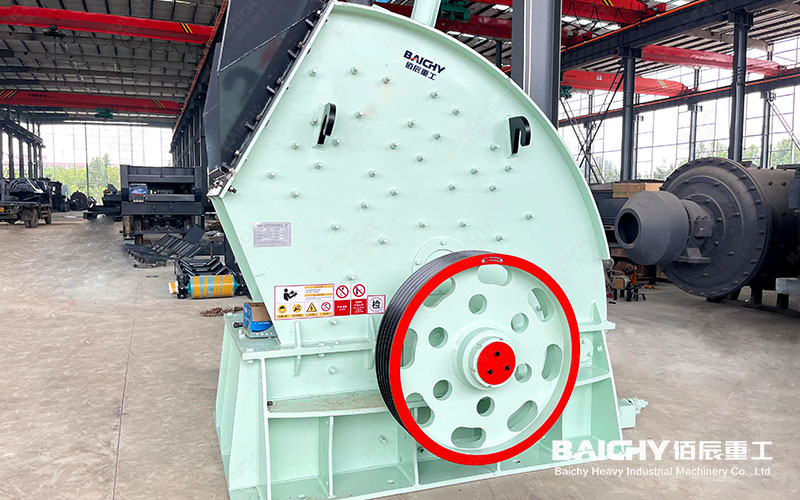

Heavy Hammer Crusher

Features: Heavy Hammer crusher uses high-speed rotating hammers to impact materials to crush them. It has the characteristics of large crushing ratio, high crushing efficiency, and uniform product particle size.

Advantages: Suitable for medium and fine crushing operations, especially for crushing limestone and other medium hardness materials.

Cone Crusher

Features: Cone crusher crushes materials by rotating and squeezing the cone, and has the advantages of high crushing efficiency, low energy consumption, and adjustable product particle size.

Advantages: Suitable for medium and fine crushing operations, especially suitable for processing high-hardness limestone, and easy to realize automatic control.

Double Roller Crusher

Features: Double Roller Crusher crushes materials by squeezing materials through two relatively rotating rollers, and has the characteristics of adjustable crushing particle size, low energy consumption, and low noise.

Advantages: Especially suitable for production scenarios with strict requirements on crushing particle size, such as sand production lines.

Key points for selecting a limestone crusher

Crushing efficiency: Select equipment with high crushing efficiency and large processing capacity to meet the needs of efficient production.

Stability: The equipment should have good stability and reliability, and be able to operate stably in various harsh working environments.

Durability: Wearing parts such as hammers and liners should be made of high-quality wear-resistant materials to extend the service life of the equipment and reduce maintenance costs.

Energy consumption: Select a crusher with a high energy efficiency ratio and energy saving to reduce energy consumption and cost in long-term operation.

Automation degree: Consider the automation degree of the equipment, such as automatic feeding, automatic discharging, remote monitoring, etc., to improve production efficiency and reduce labor intensity.

Actual case of limestone crusher

In an efficient limestone crushing plant, multiple types of crushers are usually selected for combination according to the production scale and raw material characteristics. For example, a jaw crusher can be used for coarse crushing, and then a cone crusher or a hammer crusher can be used for medium and fine crushing, and finally, a finished product that meets the requirements can be obtained through screening equipment. This combination can give full play to the advantages of various crushers and improve crushing efficiency and product quality.

In summary, when selecting a limestone crusher, an efficient limestone crushing plant should comprehensively consider multiple factors such as equipment crushing efficiency, stability, durability, energy consumption, and automation degree to ensure the efficiency and economy of production.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.