The working principle of the high-frequency dewatering screen is mainly based on the principle of high-frequency vibration and screening. Specifically, its working principle can be decomposed into the following steps:

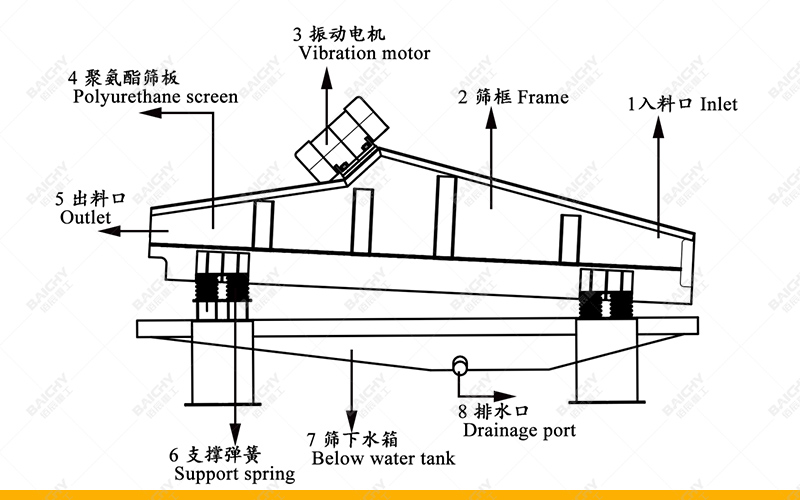

Vibration generation: The high-frequency dewatering screen is usually equipped with a high-frequency vibration motor as an excitation source. When the motor starts, it generates a high-frequency rotational force, which is converted into the vibration of the screen frame through a specific mechanical structure (such as an eccentric block).

Screen frame vibration: The excitation force generated by the vibration motor causes the screen frame to vibrate at high frequency along a predetermined trajectory (such as a straight trajectory or an elliptical trajectory). This vibration causes the material on the screen to be continuously impacted and thrown.

Material stratification: Under the vibration of the screen frame, the material forms a dynamic stratification on the screen. Finer and lighter particles will quickly pass through the screen aperture, while larger and heavier particles will be left above the screen and gradually move forward to the discharge end.

Solid-liquid separation: For materials that need to be dehydrated, high-frequency vibration not only promotes the relative movement between particles but also helps the moisture in the material to be discharged through the screen aperture. In this way, the material is screened while achieving solid-liquid separation.

Continuous operation: The high-frequency dewatering screen can work continuously, constantly feeding new materials into the screen frame, while discharging the screened materials and separated water. This continuous operation mode greatly improves production efficiency.

Anti-blocking technology: In order to prevent fine particles from accumulating and clogging on the screen, the high-frequency dewatering screen is usually equipped with anti-blocking technology. These technologies may include the adjustment of vibration intensity, the optimization of the screen structure, and auxiliary cleaning devices to ensure the smooth progress of the screening process.

The high-frequency dewatering screen realizes efficient screening and dehydration of materials through high-frequency vibration and screening principles. Its working principle is simple and efficient, and it is widely used in many industries such as mining, building materials, and coal preparation.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.