Impact Crushers And Mills With A Horizontal Shaft For Recycling Concrete

In today's world, where construction waste management and resource recycling are increasingly important, concrete recycling has become a key link in global environmental protection and sustainable development. As a manufacturer of mining crushing equipment with 20 years of experience, we are committed to providing comprehensive solutions for the global mining and construction waste management industries.

Horizontal shaft impact crushers and mills, as core equipment in concrete recycling, are revolutionizing the waste recycling field with their high efficiency, energy saving, and versatility. This article will delve into the technical advantages, application scenarios, and practical cases of these two types of equipment, providing a reference for industry customers.

| Key Words | Limestone Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Product Advantages

1. High-efficiency crushing and shaping capabilities: The horizontal shaft impact crusher uses a high-speed rotating rotor to impact concrete blocks, achieving efficient crushing and particle shaping, producing materials with excellent particle shape, suitable for use as recycled aggregate.

2. Energy saving and environmental protection: The equipment design emphasizes low-energy operation, combined with the fine grinding function of the mill, significantly reducing energy consumption and meeting green production standards.

3. Versatile adaptability: Whether in a fixed concrete recycling plant or a mobile construction site, our equipment can be flexibly configured to meet perse processing needs.

4. Durable and Easy to Maintain: Constructed with high-strength materials, it boasts strong wear resistance, low maintenance costs, and ensures long-term stable operation.

5. Intelligent Control: Equipped with an advanced automation system, it monitors equipment status in real time, optimizes crushing efficiency, and reduces manual intervention.

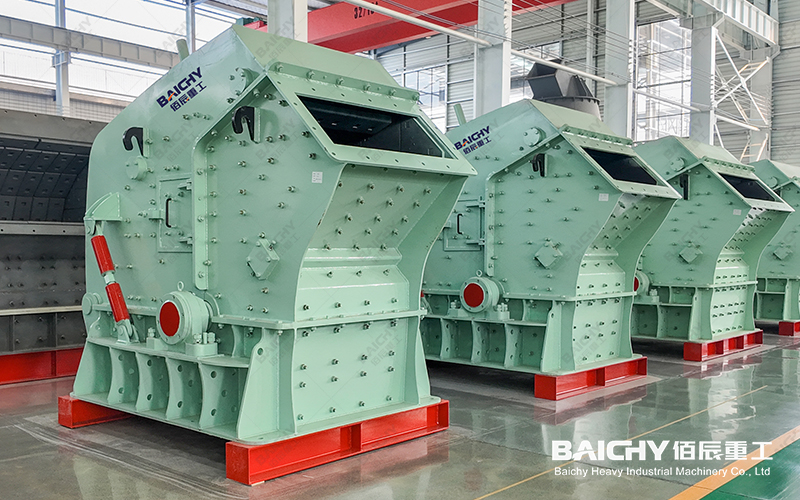

PF Impact Crusher Crushing Site

Application Scenarios

• Construction Demolition Waste Processing: Crushes waste concrete into recycled aggregate for use in road base courses or new concrete production.

• Urban Renewal Projects: In confined urban spaces, mobile horizontal shaft impact crushers enable on-site recycling, reducing transportation costs.

• Mining-Related Recycling: Extracts usable materials from mine tailings or waste building materials, improving resource utilization.

• Disaster Reconstruction Projects: Quickly processes post-earthquake or post-disaster concrete debris, accelerating the reconstruction process.

Project Case Study

In a large-scale urban renewal project in Southeast Asia, we deployed a mobile horizontal shaft impact crusher system for our client. This system processes 150 tons of waste concrete per hour, producing recycled aggregate for local road construction, helping the client reduce material costs by 30% and landfill waste by 80%. The equipment operates stably and has received high praise from customers.

FAQ

Q: What is the maximum feed size for concrete processed by the horizontal shaft impact crusher and mill?

A: Depending on the model, the maximum feed size can reach 500-800mm, depending on the configuration.

Q: Does the quality of the recycled aggregate meet international standards?

A: Yes, the aggregate produced by our equipment undergoes rigorous testing and meets international standards such as ASTM, making it suitable for various construction applications.

Q: Is the equipment suitable for processing high-humidity concrete?

A: Yes, we provide anti-clogging designs and wear-resistant components to adapt to different humidity conditions.

Q: How is after-sales service guaranteed?

A: We have service centers worldwide, providing installation training, regular maintenance, and rapid spare parts support to ensure continuous and efficient equipment operation.

Concrete recycling is not only a technical challenge but also a responsibility for resource recycling. Choosing a reliable equipment partner will inject sustainable competitiveness into your projects.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.