Jaw crusher is mainly used for the coarse crushing of various hard, medium-hard, and soft materials. It has the advantages of strong crushing capacity, good wear resistance, low failure rate, and stable operation. In the process of granite crushing, a jaw crusher is usually used as the first stage of crushing equipment, which can crush large pieces of granite into smaller particles, providing convenience for subsequent processing.

Characteristics of jaw crusher for granite crushing

1. Large feed particle size: The feed particle size of the jaw crusher is relatively large, and it can handle large pieces of granite raw materials.

2. Large crushing ratio: Through the extrusion of a jaw crusher, granite can be effectively crushed into smaller particles with a large crushing ratio.

3. Good wear resistance: The crushing parts of the jaw crusher such as the movable jaw and fixed jaw are usually made of high-strength materials, with good wear resistance, which can extend the service life of the equipment.

4. Easy maintenance: The structure of the jaw crusher is relatively simple, which is convenient to maintain and can reduce the maintenance cost of users.

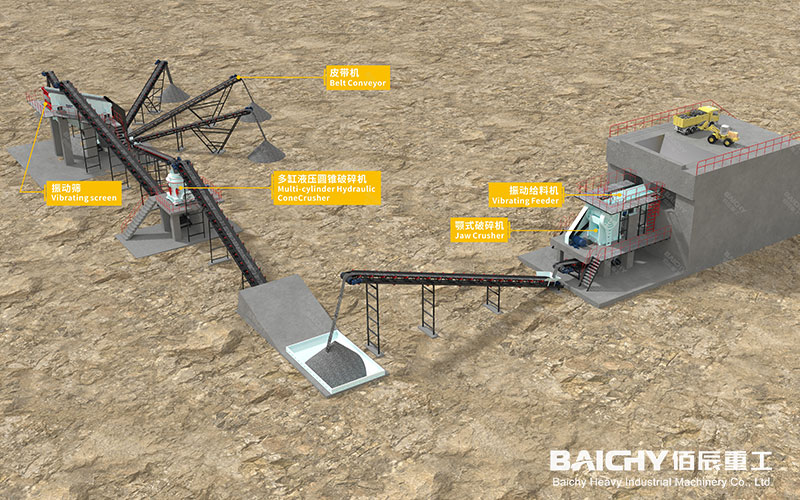

In actual applications, granite crushing production lines are usually equipped with multiple crushing equipment, among which the jaw crusher is the first stage of crushing equipment, followed by cone crusher, impact crusher, and other equipment for further crushing and shaping. For example, PE1200×1500 jaw crusher is a commonly used equipment for granite crushing, with an output of 400-1000 tons/hour, which can meet the needs of large-scale granite crushing.

Choose the appropriate jaw crusher model according to the hardness, particle size, and production requirements of the granite to ensure that the crushing effect and production capacity meet the requirements. Avoid damage to the equipment or affect the crushing effect due to too large or too small feed particle size.