Ball mill grinding media

In mining crushing and beneficiation processes, grinding media, grinding materials, and grinding balls are core technical elements that determine the final grinding efficiency, product fineness, and operating costs. As a mining crushing equipment manufacturer with 20 years of experience, we understand that the synergistic selection of these three factors directly impacts the mill's production capacity, energy consumption, and the lifespan of wear-resistant parts. Many clients often overlook these internal details when optimizing their production lines, leading to low grinding efficiency and high overall costs. This article will delve into the definitions, relationships, and selection strategies of these three elements to help you achieve cost reduction and efficiency improvement.

Definitions and Functional Analysis

Grinding Material: This usually refers to the ore raw material being ground. Its physical and chemical characteristics (such as hardness, particle size, moisture content, and abrasiveness) are the basis for selecting subsequent grinding media.

Grinding Media: This broadly refers to all consumable bodies used for impacting and grinding materials within a mill (such as a ball mill or rod mill). It is a general category.

Grinding Ball: This is the most common and widely used specific form of grinding media, a subcategory under it. In ball mills, they crush materials through dropping, impact, and rolling.

Simply put, grinding material is the object being processed, grinding media is the general term for the processing tools, and grinding ball is one of the most mainstream tool forms.

Advantages: Core Value Brought by Scientific Selection

Correctly selecting high-quality grinding balls and other media can bring multiple significant advantages to mining operations:

1. Improved Grinding Efficiency and Increased Output: High-hardness, high-roundness grinding balls with scientifically matched sizes can maximize energy transfer, shorten the time required for materials to reach the target fineness, thereby increasing output per unit time.

2. Reduced Overall Energy Consumption: Efficient grinding means that for the same output, the motor runs for a shorter time or at a lower load, directly saving electricity costs, which is crucial for grinding operations where energy consumption accounts for a large proportion of costs.

3. Extended Replacement Cycle, Reduced Downtime: Grinding balls cast from high-quality materials such as high-chromium alloy and special steel, and treated with advanced heat treatment processes, possess extremely high wear resistance and impact toughness. The low wear rate significantly extends the replacement cycle and equipment maintenance intervals, reducing unplanned downtime.

4. Improved Product Purity and Quality: High-quality grinding balls have low wear, resulting in fewer metal impurities mixed into the product, helping to ensure the purity of the final concentrate. At the same time, the stable grinding effect leads to a more uniform product particle size distribution.

5. Optimized Overall Operating Costs: Although the unit price of high-quality grinding media may be slightly higher, the resulting benefits in increased production, energy savings, and time savings (labor and downtime) significantly reduce the cost per ton of ore processed, resulting in a high return on investment.

Ball mill customer site

Application Case: Optimization of the Grinding Section in a Certain Iron Ore Processing Plant

Background: A large domestic iron ore processing plant originally used ordinary low-chromium cast iron balls, which resulted in high ball consumption, unstable mill throughput, and problems with both over-grinding and under-grinding.

Solution: After on-site inspection and material testing by our engineers, we recommended a customized high-chromium alloy grinding ball ratio scheme:

Material Upgrade: The ball hardness (HRC) was increased from ≥45 to ≥60, while ensuring sufficient impact toughness.

Grading Optimization: Based on the feed particle size distribution, the ratio of large and small balls was redesigned, and the filling rate was also fine-tuned to optimize the movement trajectory inside the mill.

Results: After three months of operation data comparison:

Mill throughput increased by approximately 8.5%.

Grinding ball consumption decreased by 22%.

The stability of the -200 mesh product ratio improved, and over-grinding was reduced.

Overall, the cost of grinding per ton of ore decreased by approximately 15%, and the customer recovered the entire investment in media upgrades within one year.

Related Equipment Recommendations

Optimizing the three elements of grinding requires efficient grinding equipment. The following core equipment provided by our company works perfectly with high-quality grinding media:

1. Energy-saving Overflow/Grinding Ball Mill: Utilizes high-power double-row self-aligning roller bearings, offering high transmission efficiency and 10-30% lower energy consumption compared to traditional sliding bearing mills, providing a stable platform for efficient grinding.

2. Cone Crusher (Medium and Fine Crushing): Achieves more crushing, less grinding, minimizing the particle size of the material entering the mill, reducing the load on the mill from the source, and is key to improving the efficiency of the entire crushing and grinding system.

3. Automatic Grinding Media Ball Feeder: Allows for timed and quantitative automatic ball replenishment, maintaining a stable ball charge gradation inside the mill, eliminating the need for manual intervention, ensuring continuous optimal grinding efficiency, and improving safety.

Frequently Asked Questions (FAQ)

Q1: How do I choose the appropriate grinding ball material based on my ore characteristics (material)?

A1: This mainly depends on the hardness and abrasiveness of the ore. For high-hardness, highly abrasive ores (such as iron ore and copper ore), high-chromium alloy cast balls (HRC≥58) are recommended; for medium-to-low hardness ores (such as gold ore and bauxite), cost-effective medium-chromium alloy or low-chromium alloy balls can be selected. Our company can provide free material testing and selection advice.

Q2: How are the size and gradation ratio of grinding balls determined?

A2: The basic principle is large balls for crushing large particles, small balls for grinding fine powder. Larger initial feed particle sizes require a higher proportion of larger diameter balls; achieving finer products requires increasing the proportion of small and medium-sized balls. Typically, a mixture of various sizes is used (e.g., φ100mm, φ80mm, φ60mm, φ40mm). The specific gradation scheme requires precise calculation based on the mill specifications, feed and discharge particle size requirements. Our technical team can provide professional gradation design.

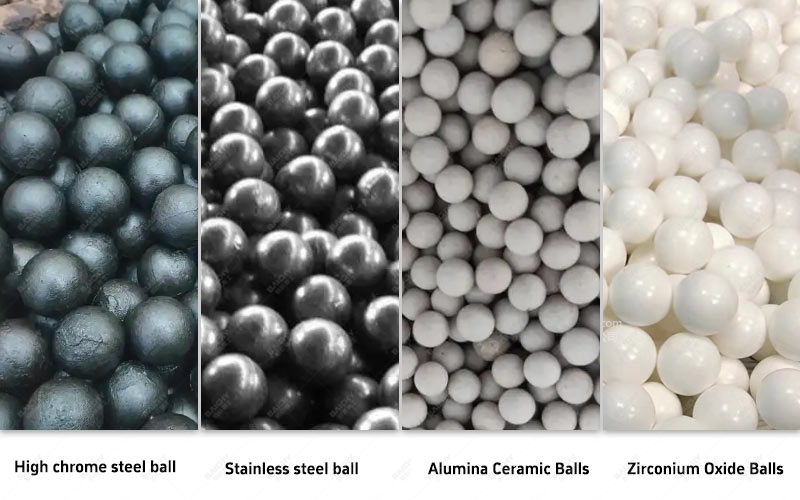

Q3: Besides grinding balls, what other common types of grinding media are there?

A3: In addition to grinding balls, other common grinding media, depending on the equipment, include:

Grinding Rods: Primarily used in rod mills, they offer strong selective crushing action, resulting in uniform product particle size and minimal over-grinding.

Ceramic Balls/Alumina Balls: Used for grinding non-metallic minerals (such as kaolin and quartz sand) or ceramic glazes where strict requirements for iron contamination exist.

Natural Flint/Pebbles: Still used in some special processes or historically significant mills.

Wear-Resistant Steel Segments: These are short cylindrical media used in some fine grinding or regrinding operations where the slurry viscosity is high.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.