The GTS1230 drum screen usually consists of a long cylindrical screen frame and a rotating drum, and the surface of the drum is covered with screen holes or screen plates of different sizes. The screen specifications of the GTS1230 drum screen may vary from manufacturer to manufacturer but generally have a larger screening area and higher screening efficiency.

How does the drum screen work?

1. Material feeding: The material enters the interior of the drum screen through the feed port.

2. Screening process: The drum starts to rotate, and the material is subjected to centrifugal force on the surface of the drum while moving along the length of the drum. Smaller particles will pass through the screen holes or screen plates, while larger particles are blocked on the screen.

3. Grading and separation: According to the size of the screen holes or screen plates, the material is divided into different size classes. Smaller particles pass through the screen holes or screen plates, while larger particles are retained on the drum surface.

4. Discharging: After screening, materials of different sizes move forward along the length of the drum and are discharged from the drum screen through the discharge port.

A mining dryer, also known as a rotary drum dryer, is a kind of equipment widely used in building materials, metallurgy, chemical industry, cement industry, and other fields. It is mainly used for drying slag, limestone, coal powder, clay, and other materials.

Working principle of rotary dryer

After the wet material is added to the dryer, the material is evenly distributed and dispersed in the dryer under the rotation of the lifting plate evenly distributed in the rotating body and is fully in contact with the co-current (or countercurrent) hot air. As the drum rotates, the material moves to the lower end under the action of gravity, is heated and dried by hot air during the drying process, and is finally discharged from the discharge end.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

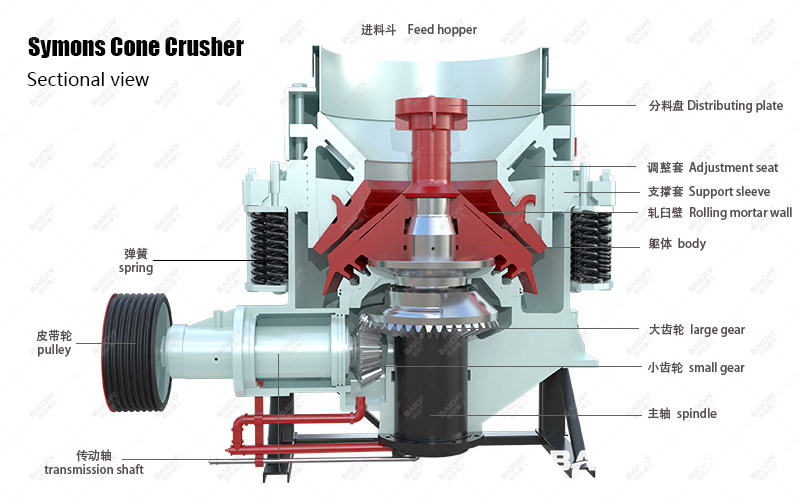

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.