Impact Crusher, Sand Making Machine, Stone Crushing Equipment

In the mining and construction aggregate production sector, the performance of crushing equipment directly determines the output efficiency and finished product quality of the production line. As a manufacturer of mining crushing equipment with 20 years of deep industry experience, we are committed to providing global customers with efficient and reliable crushing solutions for all scenarios. Impact crushers, as one of the core equipment in modern stone processing, are becoming the preferred choice for medium-hard material crushing and shaping processes due to their unique crushing principle and superior performance.

| Key Words | Impact Crusher For Stone Processing |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Product Overview

Impact crushers, also known as sand making machines, employ a combined stone-on-stone and stone-on-iron working principle. Material is accelerated and projected under the action of a high-speed rotating impeller, resulting in violent impacts and collisions with the surrounding material lining or impact blocks, thereby achieving efficient crushing and shaping of the material. This equipment is particularly suitable for crushing abrasive materials with medium to high hardness, such as granite, basalt, river pebbles, and slag, and performs exceptionally well in manufactured sand production and high-grade aggregate shaping.

Core Advantages

1. Unique peripheral guard plate structure and crushing chamber shape: This ensures the finished particles are regular polyhedrals with low needle-like and flaky content and continuous gradation, greatly enhancing the commercial value of the aggregate.

2. Stable operation and easy maintenance: Key components such as bearing seats utilize an integral cast steel structure, offering high strength and impact resistance. A hydraulic opening device makes core maintenance safe and convenient, significantly reducing downtime.

3. Multi-purpose and flexible configuration: Simple adjustments allow for switching between stone-on-stone and stone-on-iron modes, meeting the needs of different processes such as crushing, shaping, and sand making, flexibly adapting to various working conditions.

4. Environmentally friendly, intelligent, reliable, and durable: The equipment features a well-sealed structure and a comprehensive dust removal and noise reduction design, meeting environmental protection requirements. It can be integrated with an automated control system for intelligent monitoring and fault warning. Core wear-resistant parts are made of high-quality alloy materials, ensuring a long service life.

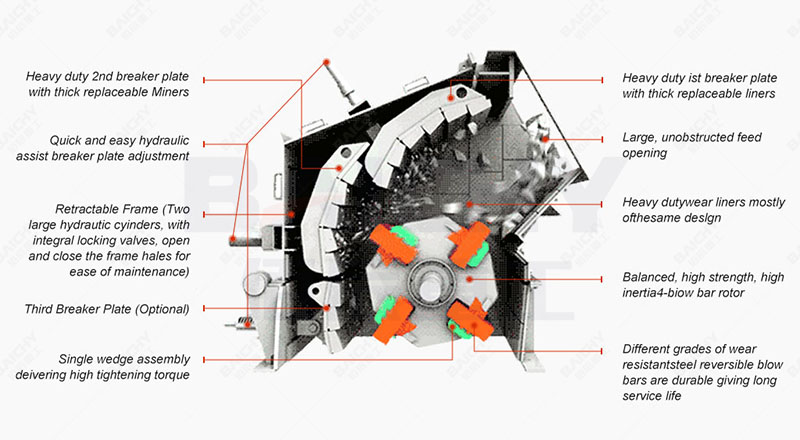

PF Impact Crusher Structure Diagram

Typical Application Scenarios

• Mechanized Sand and Aggregate Production: Used in large-scale sand and gravel aggregate production lines for tertiary crushing (fine crushing) and sand shaping to produce high-quality sand and gravel that meets national construction standards.

• Mining Fine Crushing Operations: Used in metal and non-metal mines for fine crushing of medium-hardness ores, providing raw materials with ideal particle sizes for subsequent grinding processes.

• Building Materials and Metallurgy: Used for crushing materials such as cement clinker, slag, and quartz, and is a key piece of equipment in the building materials, glass, and ceramics industries.

• Infrastructure Construction: Supplying high-quality aggregates for major projects such as highways, high-speed railways, hydropower dams, ports, and airports.

• Construction Waste Recycling: Crushing and shaping demolished building concrete to produce recycled aggregates, achieving resource recycling.

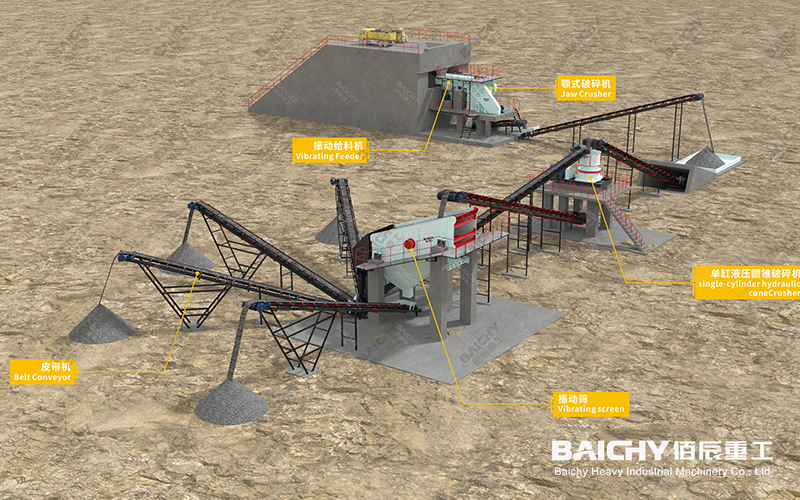

Aggregate crushing plant

Global Project Cases

With 20 years of technical accumulation and project experience, our equipment has served more than 50 countries and regions worldwide. For example, in a large-scale granite aggregate project in Southeast Asia, we configured multiple high-performance impact crushers to build a modern production line with a capacity of 800 tons per hour. The high-quality manufactured sand and aggregates produced by this production line have excellent particle shape and stable gradation, fully meeting the construction standards of local mega-bridge projects and earning high praise from the client. Furthermore, in an infrastructure construction project in the Middle East, our equipment maintained continuous and stable high output even in harsh environments with high temperatures and dust, demonstrating outstanding reliability.

Frequently Asked Questions (FAQ)

Q1: What are the main differences between impact crushers, cone crushers, and jaw crushers?

A1: Impact crushers use impact energy for crushing, producing products with good particle shape, and are mostly used for fine crushing and shaping; jaw crushers use compression crushing, used for primary coarse crushing; cone crushers use layered crushing, used for medium and fine crushing, with high output, but relatively poor particle shape. These three are often used together to form a complete crushing production line.

Q2: What is the lifespan of the wear parts of the equipment? Is replacement complicated?

A2: We use high-performance wear-resistant parts such as ultra-high chromium alloy or ceramic composite materials, resulting in a lifespan far exceeding the market average. The equipment design prioritizes ease of maintenance; a hydraulic opening device allows for quick and easy replacement of wear parts such as flow channel liners and throwing heads.

Q3: Can it be used for crushing wet materials?

A3: The standard impact crusher is mainly suitable for materials with medium to low moisture content. For viscous materials or materials with high moisture content, we can provide targeted cavity designs and anti-clogging solutions, or recommend pre-drying treatment.

Q4: How to control the fineness modulus of the finished sand?

A4: By adjusting parameters such as rotor speed, feed rate, and distributor opening, the finished particle size can be flexibly controlled. Furthermore, the equipment can form a closed-loop circulation with a vibrating screen to precisely control the fineness and gradation of the final product.

Q5: Can your company provide a complete solution rather than just a single machine?

A5: Of course. As a full-scenario solution provider, we can not only provide a complete set of equipment from coarse crushing, medium crushing to fine crushing, shaping and screening, but also be responsible for production line process design, civil engineering guidance, installation and commissioning, operation training and after-sales maintenance support, providing customers with one-stop turnkey engineering services.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.