There are significant differences between spiral sand washing machines and wheel sand washing machines in many aspects. The following is a detailed analysis of their differences:

1. Composition structure:

• Spiral sand washing machine: mainly consists of a spiral shaft, spiral blade, screen, and driving device. The spiral blades are fixed on the spiral shaft, and the driving device drives the spiral shaft to rotate. The spiral blades rotate accordingly to clean and screen the sand and gravel.

• Wheel sand washing machine: consists of driving device, roller, reducer, and spray pipe. The driving device drives the drum to rotate, and the drum is equipped with blades to clean the sand and gravel through rotation and liquid action.

2. Working principle:

• Spiral sand washing machine: The sand and gravel are mainly stirred through the spiral device in the equipment so that the soil in the sand and gravel is mixed with water and discharged from the outlet on the equipment, while the sand and gravel are gradually screened under the action of the spiral device And discharged from the discharge port at the top.

• Wheel sand washing machine: uses hydraulic force to clean and classify sand and gravel. The sand and gravel enter the screen through the feed hopper and move upward along the obliquely rising screen under the push of the propeller. As the sand and gravel rise, unclean impurities and soil are washed away by the water and dispersed, while the clean sand and gravel slide downward through the gaps in the screen.

3. Application areas:

• Spiral sand washing machine: suitable for processing sand with high mud content, strong viscosity, or different particle thicknesses. It is especially suitable for washing, grading, impurity removal, and other operations in metallurgy, building materials, hydropower, and other industries. It is especially suitable for construction sand and road construction sand and gravel.

• Wheel sand washing machine: suitable for processing sand with fine particles and weak viscosity, such as river sand, sea sand, etc. It has simple operation, good cleaning effect, wide cleaning range, and can achieve continuous operation without human supervision.

4. Sand washing effect:

• Spiral sand washing machine: suitable for processing small-grained sand and gravel. Through the rotation and pushing of the spiral blades, the sand and gravel can be classified and screened.

• Wheel sand washing machine: The sand washing effect is relatively thorough and suitable for processing large particles of sand and gravel. The high-speed rotating wheels are used to generate strong impact and impact force, which can effectively remove the adherent substances on the surface of sand and gravel, and realize the separation and classification of sand and gravel.

5. Performance characteristics:

• Spiral sand washing machine: It has the characteristics of low power consumption, high cleanliness, good sealing structure, fully enclosed transmission device, adjustable weir plate, etc., ensuring that the product is efficient, durable, and has good cleaning and dehydration effects.

• Wheel sand washing machine: simple structure, durable, small footprint, and stable output. However, it cannot clean materials with excessive mud content and mud balls in the materials.

There are obvious differences between spiral sand washing machines and wheel sand washing machines in terms of structure, working principle, application fields, sand washing effect, and performance characteristics. Which sand washing machine to choose mainly depends on the specific production needs and material characteristics.

There are significant differences between spiral sand washing machines and wheel sand washing machines in many aspects. The following is a detailed analysis of their differences:

1. Composition structure:

• Spiral sand washing machine: mainly consists of a spiral shaft, spiral blade, screen, and driving device. The spiral blades are fixed on the spiral shaft, and the driving device drives the spiral shaft to rotate. The spiral blades rotate accordingly to clean and screen the sand and gravel.

• Wheel sand washing machine: consists of driving device, roller, reducer, and spray pipe. The driving device drives the drum to rotate, and the drum is equipped with blades to clean the sand and gravel through rotation and liquid action.

2. Working principle:

• Spiral sand washing machine: The sand and gravel are mainly stirred through the spiral device in the equipment so that the soil in the sand and gravel is mixed with water and discharged from the outlet on the equipment, while the sand and gravel are gradually screened under the action of the spiral device And discharged from the discharge port at the top.

• Wheel sand washing machine: uses hydraulic force to clean and classify sand and gravel. The sand and gravel enter the screen through the feed hopper and move upward along the obliquely rising screen under the push of the propeller. As the sand and gravel rise, unclean impurities and soil are washed away by the water and dispersed, while the clean sand and gravel slide downward through the gaps in the screen.

3. Application areas:

• Spiral sand washing machine: suitable for processing sand with high mud content, strong viscosity, or different particle thicknesses. It is especially suitable for washing, grading, impurity removal, and other operations in metallurgy, building materials, hydropower, and other industries. It is especially suitable for construction sand and road construction sand and gravel.

• Wheel sand washing machine: suitable for processing sand with fine particles and weak viscosity, such as river sand, sea sand, etc. It has simple operation, good cleaning effect, wide cleaning range, and can achieve continuous operation without human supervision.

4. Sand washing effect:

• Spiral sand washing machine: suitable for processing small-grained sand and gravel. Through the rotation and pushing of the spiral blades, the sand and gravel can be classified and screened.

• Wheel sand washing machine: The sand washing effect is relatively thorough and suitable for processing large particles of sand and gravel. The high-speed rotating wheels are used to generate strong impact and impact force, which can effectively remove the adherent substances on the surface of sand and gravel, and realize the separation and classification of sand and gravel.

5. Performance characteristics:

• Spiral sand washing machine: It has the characteristics of low power consumption, high cleanliness, good sealing structure, fully enclosed transmission device, adjustable weir plate, etc., ensuring that the product is efficient, durable, and has good cleaning and dehydration effects.

• Wheel sand washing machine: simple structure, durable, small footprint, and stable output. However, it cannot clean materials with excessive mud content and mud balls in the materials.

There are obvious differences between spiral sand washing machines and wheel sand washing machines in terms of structure, working principle, application fields, sand washing effect, and performance characteristics. Which sand washing machine to choose mainly depends on the specific production needs and material characteristics.

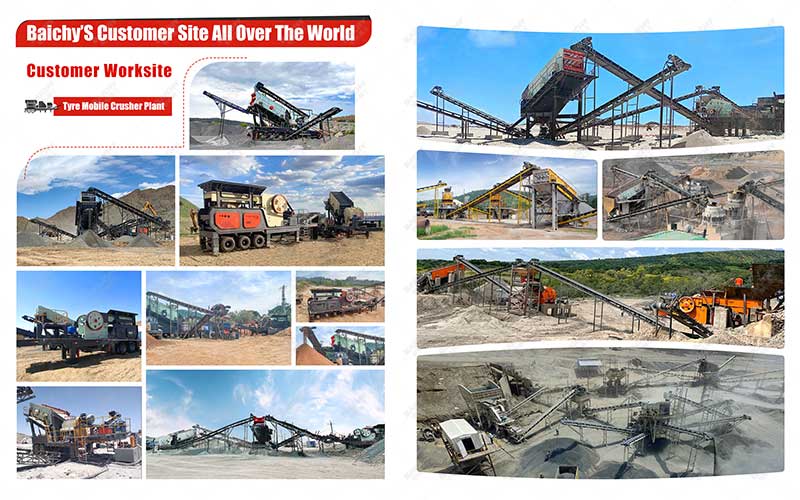

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)