YDPZ75-1142 jaw mobile crushing plant + YDPZ300-2160 cone mobile crushing plant are the mobile crushing equipment recommended by Baichy. The two equipments form a closed production line, which is used to crush 300-600mm raw ore to 15-80mm.

Coarse crushing equipment

Type: jaw crusher (mobile or fixed, selected according to site conditions)

Function: Preliminary crushing of large pieces of raw ore of 300-600mm to reduce its size to the feeding requirements of subsequent fine crushing equipment.

Processing capacity: Ensure that the processing capacity is greater than or equal to 200tph to match the overall capacity of the production line.

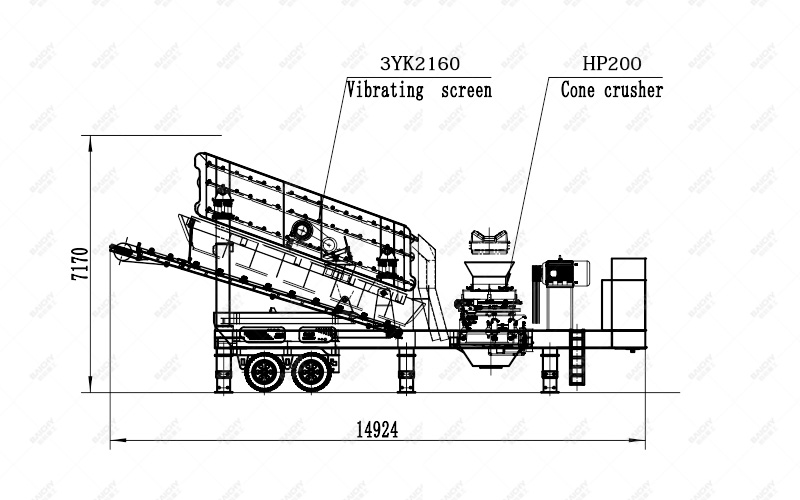

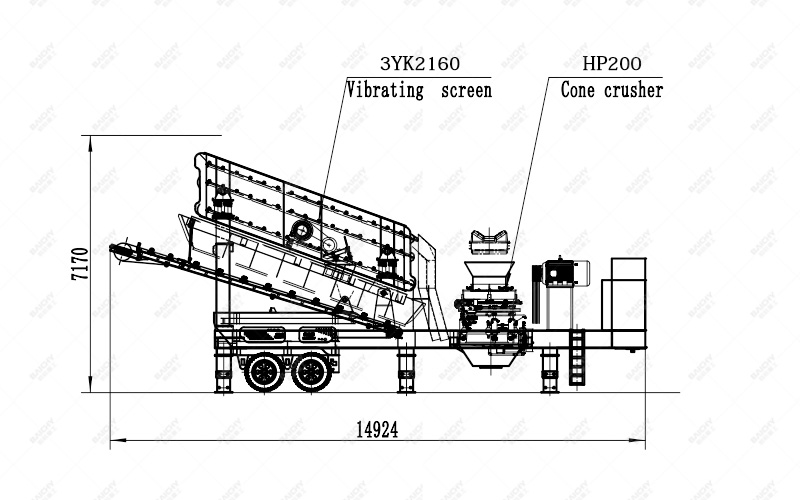

Fine crushing and screening equipment

Type: cone crusher (or impact crusher, selected according to the hardness and particle size requirements of the ore) + vibrating screener (integrated or independent)

Function: The cone crusher further crushes the coarsely crushed materials to a range of 15-80mm; the vibrating screener screens the finely crushed materials to separate finished materials of different particle sizes.

Processing capacity: Match with the first equipment to ensure the smooth operation of the entire production line.

Production line workflow

1. Raw material input: Use a loader or excavator to feed large pieces of raw ore into the feed port of the first jaw crusher.

2. Coarse crushing: The raw ore is squeezed and sheared in the jaw crusher and crushed into smaller pieces.

3. Conveying: The coarsely crushed materials are sent to the cone crusher of the second equipment through a conveyor belt for fine crushing.

4. Fine crushing and screening: The cone crusher crushes the material to the required particle size range, and then screens it through a vibrating screener to obtain finished materials of different particle sizes.

5. Finished product output: The screened finished material is sent to the storage area or the next process link through a conveyor belt.

Precautions

1. Equipment selection: When selecting equipment, factors such as the nature of the raw materials, particle size distribution, production capacity and site conditions should be fully considered to ensure that the equipment can meet the overall requirements of the production line.

2. Maintenance: Regularly maintain the equipment, including checking wear parts, replacing lubricating oil, cleaning the crushing chamber, etc., to ensure the normal operation of the equipment and extend its service life.

3. Safe operation: The operator should be familiar with the operating procedures and safety precautions of the equipment to ensure that no safety accidents occur during operation.

4. Production line optimization: According to the actual operation of the production line and the output requirements, the equipment can be appropriately adjusted and optimized to improve production efficiency and product quality.

Through the above configuration scheme and workflow, you can build a closed production line to crush 300-600mm raw ore into a particle size range of 15-80mm. At the same time, you also need to pay attention to relevant matters in terms of selection, maintenance and safe operation to ensure the stable operation and efficient output of the production line.