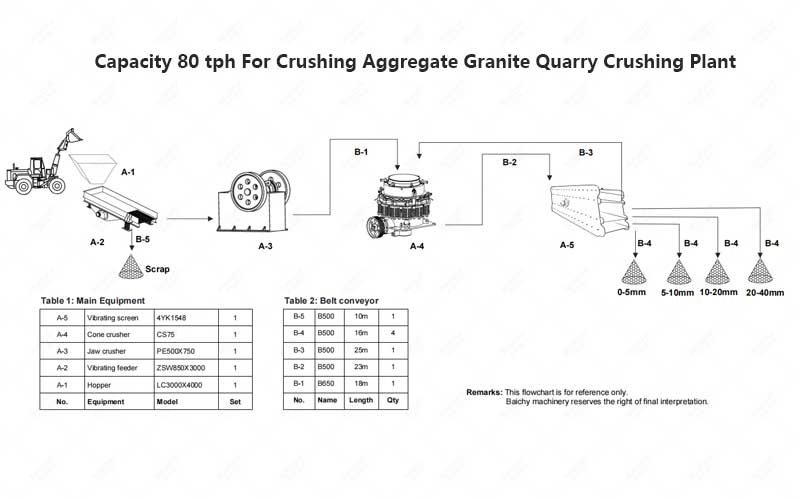

When you need an 80tph granite crushing production line, you can refer to Baichy's solution configuration, ZSW850x3000 feeder + PE500x750 jaw crusher + CS75 cone crusher + 4YK1548 vibrating screen + B500 belt conveyor + B650 belt conveyor and other equipment.

Jaw crusher is a common coarse crushing equipment in mining equipment. It is suitable for crushing soft, medium, and hard stones and is known as the "tiger's mouth". It crushes materials by extrusion, grinding, rubbing, and other methods. It is reliable, cheap, simple to maintain, and has large crushing force and a full range of models to meet the needs of customers with large and small production. It is often used as a primary crushing equipment to crush large pieces of granite.

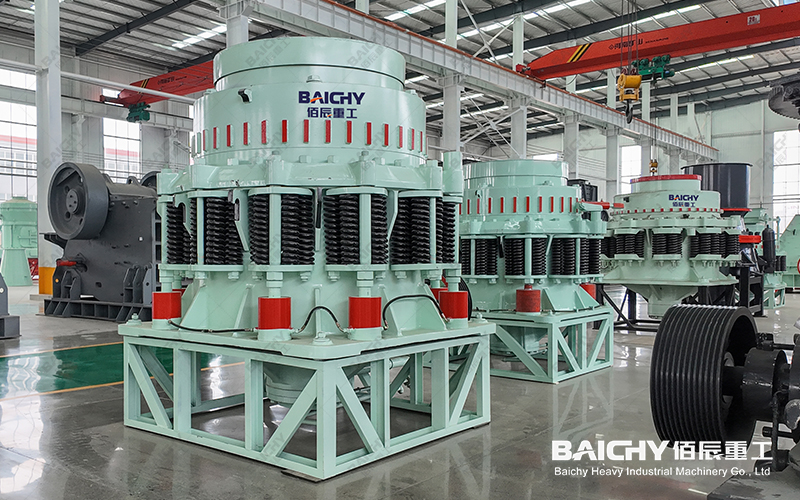

Cone crusher is a professional equipment for crushing hard stones. It adopts the principle of laminated crushing. The high speed, high crushing capacity, and design make the crushed finished product have a high-quality cubic shape. It has a large crushing ratio, high efficiency, low energy consumption, less dust, uniform product particle size, stable operation, low failure rate, and easy maintenance. It is suitable for medium and fine crushing of granite to ensure uniform particle size of the finished product.

The production capacity is 80 t/h. Equipment selection precautions for crushing granite quarry aggregates

1. Equipment selection: The appropriate crushing equipment and configuration should be selected based on comprehensive considerations such as the hardness, particle size distribution, and production needs of the granite.

2. Maintenance: Regularly maintain the equipment to ensure that the equipment is in good working condition and extend the service life of the equipment.

3. Environmental protection requirements: Attention should be paid to the environmental performance of the equipment, such as emission indicators such as noise and dust, to ensure compliance with relevant national standards and regulations.

Granite quarry aggregate crushing equipment with a capacity of 80 tons/hour can choose different types of equipment such as jaw crusher, cone crusher or mobile crushing station according to specific needs and site conditions. When selecting equipment, factors such as equipment performance, price, maintenance cost and environmental protection requirements should be fully considered.

Related recommendations: Mobile Stone Crusher