The full cost breakdown of a 50 t/h crushing equipment is a relatively complex issue, because it involves not only the purchase cost of the equipment, but also the vehicle cost, operating cost, maintenance cost and other aspects required to operate the equipment. The following is a general description based on general conditions and market information:

Equipment purchase cost of 50 t/h crushing equipment

Equipment purchase cost is one of the main costs of 50 ton/hour crushing equipment. Depending on the type, brand, configuration and other factors of the equipment, the purchase cost will vary greatly. The following are some common equipment configurations and their approximate price ranges (for reference only, the actual price may vary due to market fluctuations, brand differences and other factors):

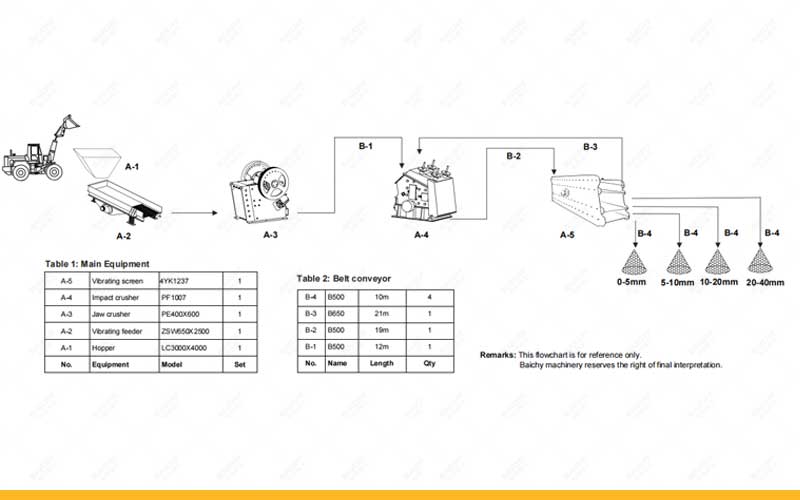

Economic configuration:

Raw material silo, vibrating feeder, jaw crusher, conveyor, impact crusher, vibrating screen and other equipment, the total investment cost may be less than 550,000 yuan.

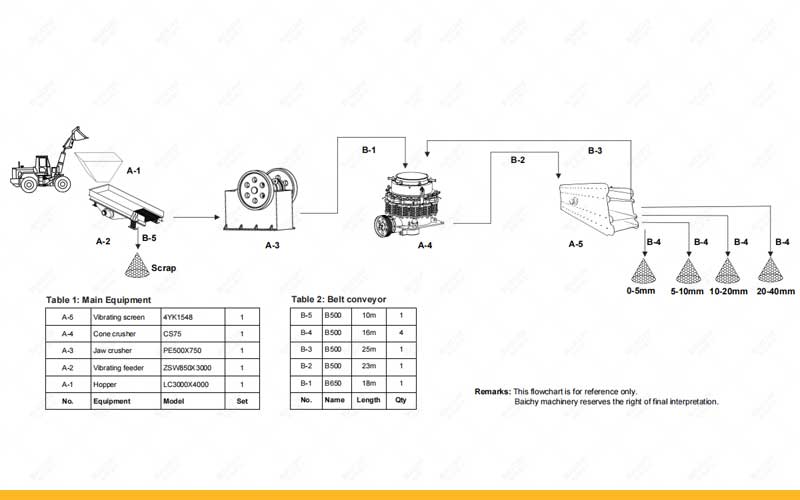

Advanced configuration:

Including jaw crusher (or cone crusher), conveyor, sand making machine, vibrating screen, sand washer and other equipment, the total investment cost may be less than 830,000 yuan.

One-time molding configuration:

Raw material silo, vibrating feeder, heavy hammer crusher, conveyor, vibrating screen and other equipment, the total investment cost may be less than 500,000 yuan.

Vehicle cost required to operate equipment

Operating 50 tons/hour crushing equipment usually requires some auxiliary vehicles, such as trucks for transporting raw materials and finished products, tractors for mobile crushers, etc. The cost of these vehicles will also vary depending on factors such as brand, model, quantity, etc. The following are some possible vehicle costs:

Trucks: used to transport raw materials and finished products, depending on the model and load capacity, the cost may range from tens of thousands to hundreds of thousands of yuan.

Tractor: If a mobile crusher is used, a tractor may be required for movement and positioning, and the cost will also vary depending on the model and configuration.

Operation cost of 50 tons/hour crushing production line

Operation costs include power consumption, fuel consumption, staff wages, maintenance costs and other aspects. These costs will vary depending on factors such as equipment type, production scale, and operating efficiency. The following are some possible operating costs:

Power consumption: Crushing equipment usually consumes a lot of electricity, and the cost depends on the electricity price and the power of the equipment.

Fuel consumption: If the equipment is driven by diesel or other fuels, fuel consumption will also become an important operating cost.

Staff wages: A certain number of technicians and workers are required to operate and maintain the equipment, and their wages are also part of the operating costs.

Maintenance costs: Includes costs such as regular maintenance of equipment, troubleshooting, and replacement of spare parts.

Other costs of 50 tons/hour crushing production line

In addition to the above costs, some other costs may also be included, such as equipment depreciation, insurance costs, taxes, etc. These costs will also vary depending on factors such as equipment type, age, and policy environment.

Due to the influence of various factors such as market fluctuations, brand differences, equipment configuration, and operating costs, it is difficult to give a specific number for the full cost details of 50 tons/hour crushing equipment. But it is certain that the equipment purchase cost, the cost of the vehicle required to operate the equipment, the operating cost, and other costs are all important factors in the total cost. Therefore, when investing in equipment, it is necessary to comprehensively consider various factors and formulate a reasonable investment budget and operating plan.

Related recommendations: 200-300tph Basalt Crushing ProductionLine in Mexico