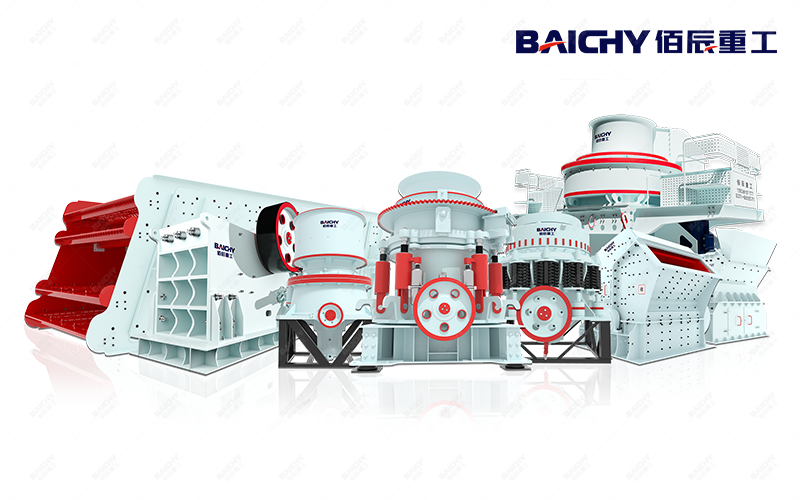

With the rapid development of national infrastructure and industrial construction, the types and models of crushers are indeed increasing, and customers will inevitably encounter confusion when choosing. The following will focus on how to choose a suitable crusher and the price of the crusher for a detailed analysis:

How many types of crushers are there?

According to the working principle, crushers can generally be divided into extrusion type and impact type.

The products produced by the extrusion crusher have a low stone powder content and a large proportion of needle-shaped particles. Common types of extrusion crushers mainly include jaw crushers, gyratory crushers, cone crushers, etc. The impact crusher has a relatively simple structure, a large crushing ratio, and a good product particle shape. Common types mainly include impact crushers, hammer crushers and sand making machines.

Generally, in sand and gravel production plants, the coarse crushing process generally uses a jaw crusher, a gyratory crusher or a hammer crusher; the medium crushing process generally uses a cone crusher or an impact crusher; the fine crushing sand making process generally uses a sand making machine or a cone crusher.

1) Jaw crusher

Jaw crusher is suitable for crushing various ores and rocks, such as limestone, coal, iron ore, cement, etc. It can crush materials with compressive strength not more than 320Mpa, divided into coarse crushing and fine crushing, to meet the crushing operations with different particle size requirements.

The structural design is reasonable, the machine speed is high, and the product passes through the machine cavity at a fast speed, which further improves the production efficiency. The product technical design is reasonable, and the internal wearing parts of the machine body are made of wear-resistant materials, which has a long service life and reduces the maintenance cost.

The structure is simple, easy to manufacture and maintain, and can operate stably for a long time, reducing the downtime caused by failure.

2) Gyratory crusher

The salient feature of the gyratory crusher is its large production capacity. When the feed and discharge ports of the gyratory crusher and the jaw crusher are the same in size, the production capacity of the gyratory crusher is 2.5~3 times that of the jaw crusher.

Due to the high total investment and large amount of civil engineering, the gyratory crusher is more suitable for large-scale projects.

3) Cone crusher

Cone crusher occupies an important position in the crushing equipment market with its advantages of high efficiency, energy saving and environmental protection, reliable quality, flexible adjustment, simple operation, low maintenance cost and wide application.

Cone crusher has higher capacity and better quality, large crushing ratio and high production efficiency. By combining higher speed and stroke, the rated power and throughput of cone crusher are greatly improved, further improving production efficiency.

Cone crusher has good energy saving effect, and the innovative design incorporates dust removal device to effectively suppress dust emission and achieve green production goals.

4) Impact crusher

Impact crusher plays an important role in many industries with its advantages of high efficiency crushing and production capacity, uniform product particle size, simple structure and convenient maintenance, energy saving and environmental protection, strong adaptability, flexibility and reliability, and easy relocation and movement.

Impact crusher has high efficiency crushing capacity and production capacity, and is suitable for processing materials of various hardness, such as limestone, quartz, dolomite, iron ore, river pebbles, construction waste, etc.

Its crushing ratio is large, and it can crush materials into the required particle size to meet the needs of different industries for material crushing.

5) Sand making machine

Sand making machine plays an important role in the sand and gravel industry with its advantages of high production capacity, controllable product particle size, high material utilization rate, energy saving and environmental protection, easy maintenance and operation, strong adaptability, high quality of finished products, flexibility and convenience.

Sand making machine usually has a high single machine output and can meet the needs of large-scale production.

Sand making machine can adjust the proportion of fine powder and fine sand in the product within a certain range according to production needs to obtain an ideal particle size distribution.

How to choose a suitable stone crusher?

Sand and gravel aggregates are the basic materials for engineering construction. Their commonly used raw materials include pebbles, granite, diabase, basalt, limestone, etc. For different raw materials, the choice of stone crusher is also different.

When choosing a stone crusher, you cannot only consider one aspect, but many aspects. Crushing equipment is mainly affected by the type of material, hardness, water content, cleavage degree of inlet and outlet materials, particle size, etc., in addition to the construction site and output.

1. Material type:

Choose a suitable stone crusher according to the type of material processed in production, such as limestone, coal, granite, etc. Different materials have different hardness, moisture and cleavage characteristics, which will affect the selection of stone crushers and the crushing effect.

2. Processing capacity:

The weight of materials that a stone crusher can process per hour is an important indicator, usually in tons. According to production needs, calculate the required processing capacity to ensure that the selected stone crusher meets production requirements.

3. Feed and discharge size:

The maximum material size that a stone crusher can accept and the size of the material output are also key factors. According to the subsequent process requirements, choose the appropriate feed and discharge size to ensure the smooth production process and product quality.

Consider equipment performance

1. Crushing efficiency:

Choosing a crusher with high crushing efficiency can improve production efficiency, reduce energy consumption and cost.

2. Consumable parts and maintenance costs:

Consider the consumption of consumable parts and maintenance costs of the crusher. Choosing a crusher with durable consumable parts and low maintenance costs can reduce long-term operating costs.

3. Motor power and speed:

The motor power and speed of the crusher directly affect its crushing capacity and energy consumption. Choose the appropriate motor power and speed according to production needs to ensure stable operation and efficient crushing of the equipment.

What is the price of the crusher?

With the development of different crushers, many customers want to know the price. The price of the crusher is related to many factors, such as model, configuration, etc.

If you are interested in BAICHY crusher, you can contact us to learn about the selection, price and other details of the equipment. The engineer will introduce the machine to you in detail.

Related recommendations: Stone Crusher