vertical-roller-mill-vs-ball-mill

As a mining equipment manufacturer with 20 years of experience, we understand that grinding equipment is at the heart of the mineral processing process. Ball mills and vertical roller mills are two of the most common types of grinding equipment, but they have significant differences in principle, performance, and application. This article will provide you with an in-depth analysis to help you make the most informed choice.

Ball Mills vs. Vertical Roller Mills: A Comprehensive Comparative Analysis

In the field of mineral processing, the grinding stage after crushing is crucial, directly affecting the degree of mineral liberation and subsequent separation indicators. Ball mills and vertical roller mills are the main workhorses for this task, but their working principles and applicable scenarios are quite different.

Overview of Core Working Principles

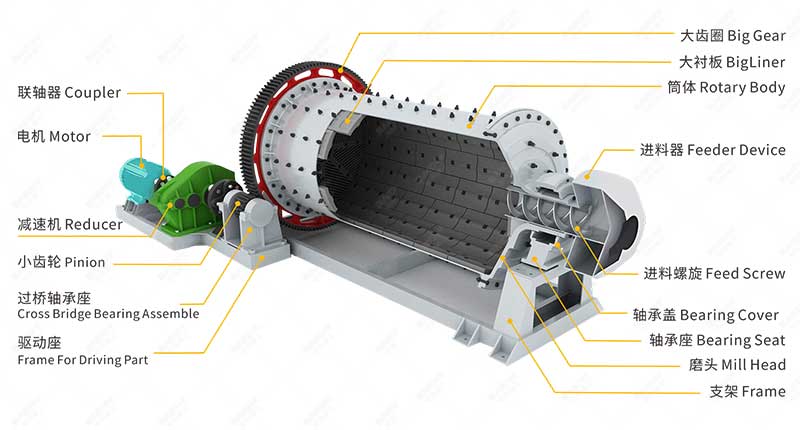

Ball Mill: Relying on Impact and Grinding

A ball mill is a horizontal rotating cylindrical device. The cylinder contains steel balls of different sizes as grinding media. When the cylinder rotates, the steel balls are lifted to a certain height and then dropped, generating strong impact and grinding forces on the material inside the cylinder, gradually crushing the material. Its process is relatively simple, and it has a very wide adaptability to the hardness and properties of the material.

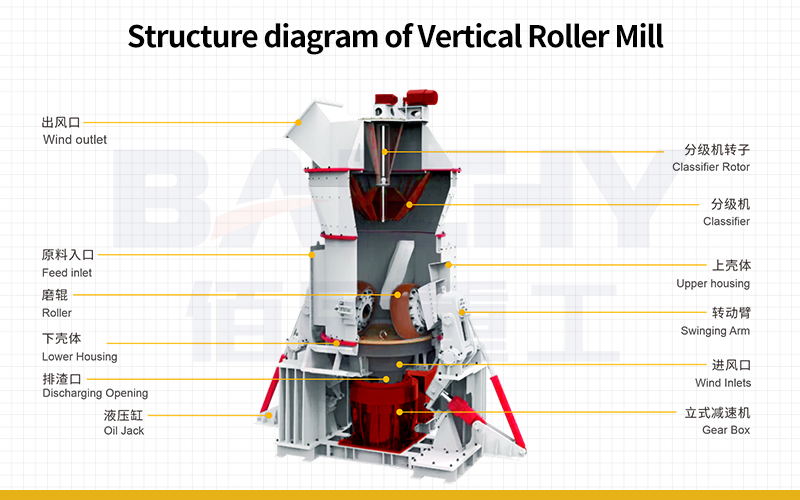

Vertical Roller Mill: Relying on Compression and Shearing

The structure of a vertical roller mill is completely different. It mainly consists of a grinding plate and grinding rollers. The material is fed from the center, falling onto the rotating grinding plate, and spreading outwards under centrifugal force. A hydraulic system applies immense pressure, causing the grinding rollers to crush the material layer. Based on the principle of crushing through a material bed, it mainly relies on compression and shearing forces to crush the material. The finely ground powder is carried by airflow to the classifier above for grading.

Comparison of Equipment Advantages and Performance Characteristics

Core Advantages of Ball Mills

Core Advantages of Ball Mills

• Strong adaptability: Can handle almost all types of ores, whether metallic or non-metallic, and performs particularly well with highly abrasive and hard materials.

• Wide range of adjustable product fineness: By adjusting the steel ball grading, grinding time, etc., it can produce products ranging from coarse particles to extremely fine powder (-325 mesh), and is especially good at producing fine and ultra-fine powders.

• Reliable operation and simple maintenance: Classic structure, mature operation and maintenance technology, and relatively low technical requirements for operators.

• Lower investment cost: Initial equipment procurement costs are usually lower than vertical roller mills of the same specifications.

Structure diagram of Vertical Roller Mill

Core Advantages of Vertical Roller Mills

• Low energy consumption and high efficiency: Using material bed grinding, energy utilization is high, typically saving 20%-30% of electricity compared to ball mill systems, which is its most prominent advantage.

• Strong drying capacity: Hot air enters from the bottom and fully contacts the material, allowing simultaneous processing of materials with up to 15% moisture content, making it very suitable for integration with drying processes.

• Small footprint: Adopting a vertical structure, the footprint is approximately 50% smaller than a ball mill system with the same production capacity.

• Low noise and low dust: Operating noise is typically 20-25 decibels lower than ball mills, and the system operates under negative pressure, resulting in less dust pollution.

Practical Application Cases and Selection Suggestions

Typical Application Scenarios

• Scenarios where ball mills are preferred:

1. Extremely abrasive ores (such as some gold and iron ores).

2. Situations requiring strict product particle size distribution or ultra-fine grinding (above -400 mesh).

3. Small and medium-sized beneficiation plants, or projects with sensitive initial investment budgets.

4. Low ore moisture content, where drying is not required.

• Scenarios where vertical roller mills are preferred:

1. Large-scale continuous production lines sensitive to energy consumption indicators (such as large-scale cement clinker and slag grinding).

2. Processes where raw materials have high moisture content and require simultaneous drying and grinding.

3. Limited plant area requiring a compact layout.

4. Plants with high requirements for working environment noise and cleanliness.

Our Equipment Recommendations

Based on twenty years of experience, we recommend:

• For customers pursuing stable reliability and processing complex and variable ores, our energy-saving overflow ball mill and grate ball mill series are time-tested choices. We have optimized the liner and transmission structure to further reduce energy consumption while ensuring reliability.

• For customers processing large volumes of homogeneous non-metallic minerals (such as limestone, calcium carbonate, and slag) and seeking ultimate energy efficiency, our new vertical roller mill integrates a high-efficiency turbo classifier and hydraulic control system, demonstrating exceptional performance in energy saving and intelligent control.

Frequently Asked Questions (FAQ)

Q1: Which type of equipment produces a more uniform product particle size?

Generally, vertical roller mills equipped with high-efficiency classifiers produce a more concentrated and uniform particle size distribution because they integrate dynamic classification, allowing qualified fine powder to be separated in a timely manner, preventing over-grinding. Ball mills have a relatively wider particle size distribution, but this can be improved by adding external classification systems (such as hydrocyclones or air classifiers).

Q2: Which is more cost-effective in terms of long-term operating costs?

This is a trade-off. Although vertical roller mills have higher initial investment costs, their extremely low power consumption and wear part consumption (for specific materials) often result in lower overall costs than ball mills in long-term (usually 2-3 years or more) large-scale operation. Ball mills have lower initial investment costs, but their operating energy consumption and maintenance costs are relatively fixed, making them suitable for projects that are sensitive to cash flow or are small to medium in scale.

Q3: What are the main differences in equipment maintenance?

Ball mill maintenance focuses on replacing liners, screens, and adding grinding balls, which is labor-intensive but simple for each inpidual task. Vertical roller mill maintenance focuses on the wear-resistant hardfacing or replacement of grinding rollers and grinding plates. This maintenance requires more specialized skills, but the maintenance cycle is usually longer, and downtime can be reduced through online hardfacing.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.