The job of a crushing plant may seem simple, breaking large pieces of rock into smaller aggregates. But in reality, something so simple is quite complex. Giant machines weighing thousands of kilograms can crush some of the hardest materials, delivering ton after ton of precious stone.

Feel free to consult

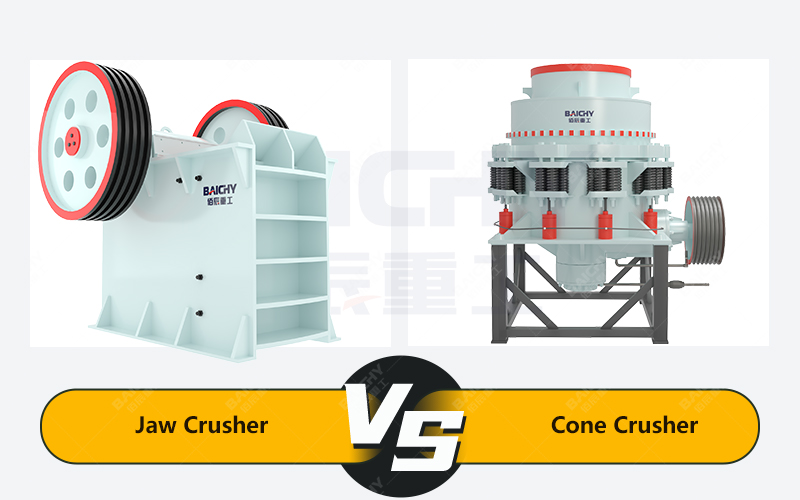

There are obvious differences between

cone crusher and

jaw crusher in working principle, application occasions, performance characteristics, feed size, production capacity, price and maintenance. When choosing, users should make comprehensive considerations based on factors such as specific material type, hardness, finished product size and actual on-site needs.

Crushing equipment has the seemingly simple job of breaking up massive boulders and rocks into smaller aggregates. Something so straightforward is quite complex in practicality. Huge machines weighing thousands of kilograms, crush some of the hardest materials ever, pumping out tonne after tonne of valuable stone.

Application scenarios of jaw crusher

Jaw Crusher is mainly used for primary crushing of materials, such as large pieces of ore, construction waste, etc. It has strong wear resistance and can crush large stones well, reducing equipment wear. Jaw crushers are widely used in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics and other industrial sectors for medium and fine crushing operations.

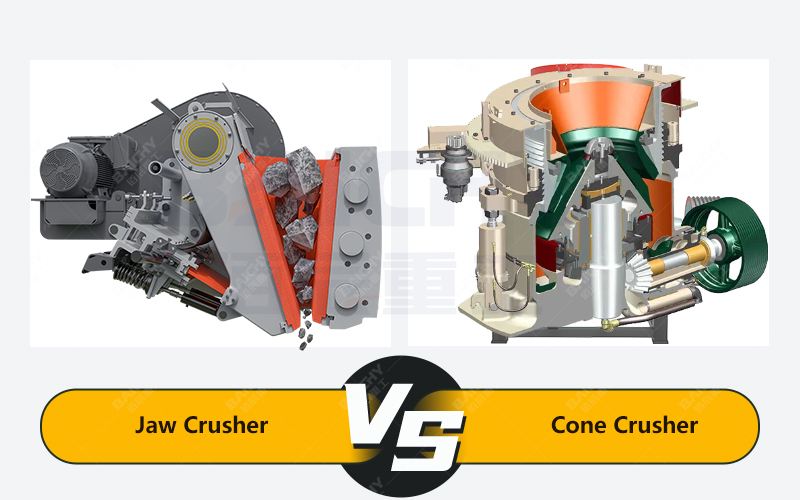

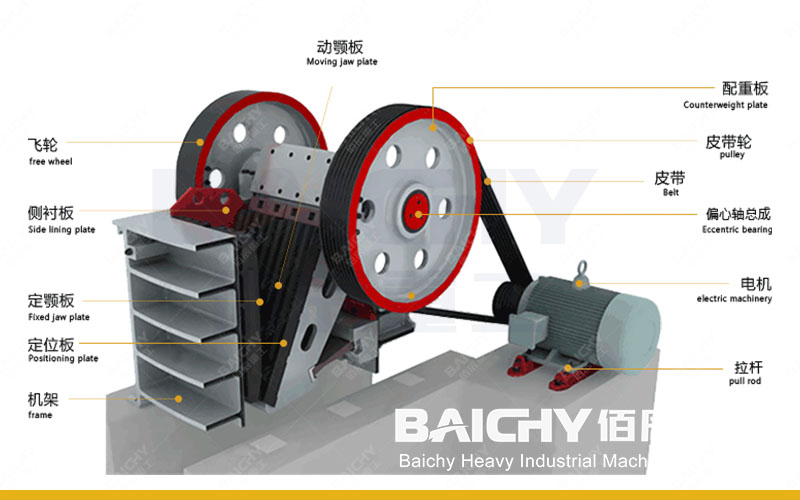

Working principle of jaw crusher

The crushing chamber is composed of two jaw plates, the movable jaw and the static jaw, which simulate the movement of the two jaws of animals to complete the material crushing operation. The movable jaw makes periodic reciprocating motion against the fixed jaw plate, sometimes separating and sometimes approaching, so as to crush the material. When the movable jaw plate approaches the fixed jaw plate, the ore between the two jaw plates is crushed by the combined action of crushing, splitting and bending and breaking; when the movable jaw plate leaves the fixed jaw plate, the crushed ore is discharged through the discharge port of the crusher under the action of gravity.

Feel free to consult

Performance characteristics of jaw crusher

1. High production efficiency, using wedge adjustment to replace the traditional pad type discharge port adjustment, so that the discharge port adjustment can be infinitely adjusted.

2. A variety of crushing chamber types, strong applicability, can meet a wide range of product particle size requirements.

3. Hydraulic adjustment of the discharge port, hydraulic cavity cleaning cylinder can quickly remove the accumulated material and difficult to crush objects in the crushing chamber, high degree of automation, easy maintenance.

4. Simple structure, easy to manufacture, reliable operation.

The feed size of

cone crusher is relatively large, and materials less than 500mm are generally acceptable (single-cylinder cone crusher), while the maximum feed size of jaw crusher varies according to different models, but is usually larger.

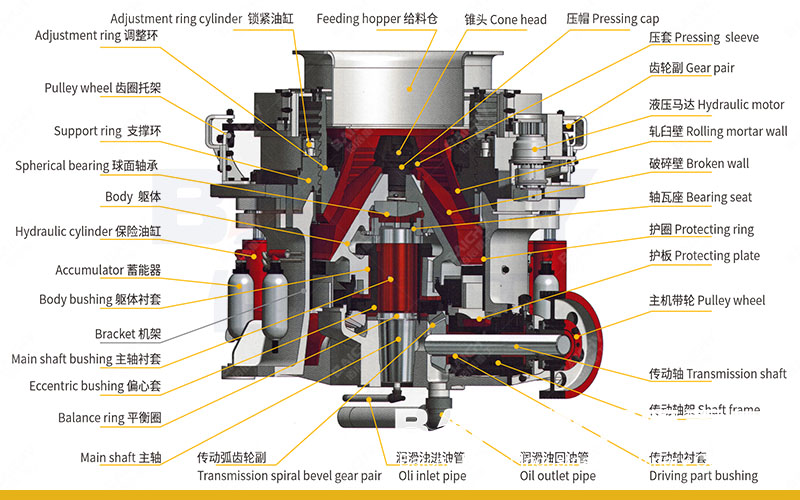

What is the working principle of cone crusher?

The laminated crushing method is adopted. The rotation of the motor drives the cone part to swing around a fixed point under the force of the eccentric sleeve, so that the crushing wall sometimes approaches and sometimes leaves the surface of the mortar wall fixed on the adjustment sleeve, so that the ore is continuously impacted, squeezed and bent in the crushing chamber and crushed. When encountering unbreakable foreign objects or machine overload, the spring safety system realizes insurance, the discharge port is enlarged, and foreign objects are discharged from the crushing chamber to protect the equipment.

Application materials and scenarios of cone crusher

Mainly used for crushing materials with medium and high hardness, such as iron ore, granite, etc., especially suitable for secondary crushing or fine crushing operations. Cone crusher is specially designed for crushing hard stones, with high crushing efficiency, good finished product particle shape, high fine particle content, and can meet the use requirements of high-quality aggregates.

Performance characteristics of cone crusher:

1. High crushing efficiency and low wear of wearing parts.

2. Good finished product shape and high fine particle content.

3. Reasonable structure, reliable operation, wear-resistant parts and low operating cost.

4. The material can be directly fed by the conveyor belt without adding silos and feeders.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.