In the realm of mining, quarrying, and recycling, jaw crushers play a crucial role in the reduction of large rocks and materials into smaller, more manageable sizes. Understanding the working principle of a jaw crusher is essential for maximizing its efficiency and ensuring smooth operation.

What Is a Jaw Crusher?

A jaw crusher, commonly known as a jaw breaker or toggle crusher, is a heavy-duty machine that utilizes compressive force to fracture and crush rocks and other solid materials. These crushers are designed to reduce the size of materials for further processing or disposal.

The Working Principle of a Jaw Crusher

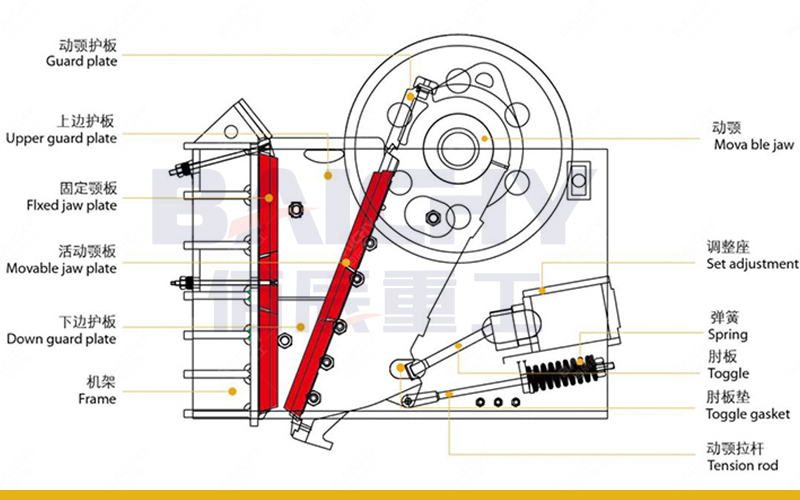

The working principle of a jaw crusher is based on the reciprocating movement of the jaw plates. The crushing chamber, which houses the jaw plates, consists of a fixed jaw (stationary jaw) and a moving jaw (swing jaw). Materials are fed into the chamber where they are compressed and crushed between the two jaws.

The Moving Jaw (Swing Jaw)

The moving jaw, also known as the swing jaw, is the active component of the jaw crusher. It is powered by an eccentric shaft that causes it to move back and forth, creating a compressive force that fractures the material. This movement is carefully controlled to optimize crushing efficiency while minimizing wear and tear on the jaw plates.

The Fixed Jaw (Stationary Jaw)

The fixed jaw, also referred to as the stationary jaw, remains in a fixed position while the moving jaw performs its reciprocating motion. The stationary jaw is typically designed with a steeper angle than the moving jaw, creating a V-shaped crushing chamber. This design allows for efficient crushing and ejection of crushed material.

Jaw Crusher Production Line Configuration

A jaw crusher is often used as the primary crusher in a production line, with subsequent stages of crushing and screening equipment arranged downstream. The entire production line is configured to achieve the desired output size and production capacity, with the jaw crusher playing a crucial role in the initial size reduction.

Jaw Crusher Manufacturer Recommendation

When it comes to selecting a jaw crusher, it is essential to choose a reputable manufacturer that offers high-quality equipment and reliable service. Our company, as a leading manufacturer of crushing equipment, offers a wide range of jaw crushers that are designed to meet the specific needs of our customers. Our jaw crushers are built with precision engineering and durable materials, ensuring reliable performance and longevity.

In conclusion, understanding the working principle of a jaw crusher is crucial for its efficient operation and maintenance. Our company provides industry-leading jaw crusher solutions that are backed by superior quality and reliable service. Whether you are looking for a primary crusher for your mining operation or a solution for material recycling, we have the right equipment for your needs. Trust us as your preferred provider of crushing equipment and discover the power of our jaw crushers.