7 Key Differences Between Impact Crushers and Hammer Crusher

In the fields of aggregate production and construction waste recycling, impact crushers and hammer crushers are indispensable key equipment for medium and fine crushing. While they may appear somewhat similar to non-experts, their core principles, applicable scenarios, and final products are vastly different. Choosing the right equipment directly impacts the efficiency, cost, and quality of the production line. As experts with twenty years of experience in manufacturing mobile crushing equipment, we will provide a thorough analysis of the differences between the two to help you make informed decisions.

| Product Name | Impact Crusher | Hammer Crusher |

| Capacity (t/h) | 15-800 | 50-800 |

| Powder (kw) | 45-355 | 37-315 |

| Max feeding size(mm) | ≤700 | ≦1200 |

Impact crusher structural diagram

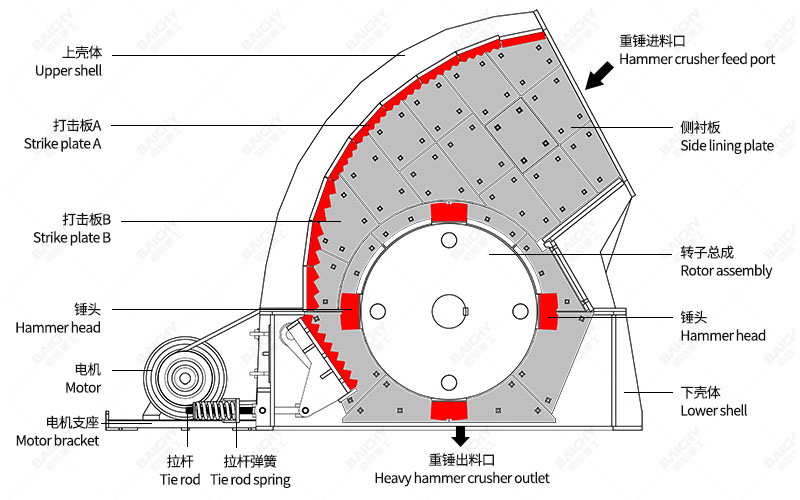

Hammer crusher structural diagram

Core Working Principle: The Fundamental Difference Between Stone-on-Stone and Hammer Crushing

This is the most fundamental difference between the two, determining all their technical characteristics.

• Impact Crusher (Impactor Crusher): Its core principle is centrifugal impact crushing and stone-on-stone crushing. Material enters the high-speed rotating rotor, is accelerated by the blow bars on the rotor, and is projected at high speed along the tangent direction, violently colliding with the material lining (or impact plate) formed in the crushing chamber. Simultaneously, the materials also collide with each other, thus achieving crushing. This process is more similar to jet collision.

• Hammer Crusher: Its core principle is hammer impact crushing. After the material enters the crushing chamber, it is directly impacted by the high-speed rotating rotor hammers. The initially crushed material is projected onto the impact plate for secondary crushing, and material smaller than the screen plate gap is discharged. This process focuses more on direct hammering.

Structural Differences: The Connection Method of Blow Bars/Hammers and the Rotor

• Impact Crusher: Uses rigidly connected blow bars. The blow bars are firmly fixed to the rotor, like a part of the rotor itself. This structure gives the rotor a higher moment of inertia, allowing it to impart greater kinetic energy to the material.

• Hammer Crusher: Uses hinged hammers. The hammers are suspended on the rotor disc by pins and can swing. When encountering unbreakable objects (such as iron blocks), the hammers can swing backward to avoid them, providing a certain degree of overload protection.

Output Particle Size and Shape Control: The Battle Between Cubical and Flaky Particles

• Impact Crusher: Due to its stone-on-stone crushing principle and multiple collisions, the finished product has excellent particle shape, mostly cubical, with low flaky content. This is crucial for producing high-grade concrete aggregates. Output particle size can be easily controlled by adjusting the rotor speed and impact plate gap, offering a wider adjustment range and greater flexibility.

• Hammer Crusher: The finished product has a relatively poor particle shape, with a higher flaky content. Output particle size is mainly controlled by the gaps in the bottom grate (screen plate). Once the grate gap is set, the adjustment range is relatively limited, and clogging is prone to occur.

Wear Part Wear and Maintenance Costs

• Impact Crusher: The main wear parts are the impact plates and impact liners. Due to the stone-on-stone crushing, wear occurs more on the contact surfaces of the material. When crushing highly abrasive materials, wear costs may be higher, but replacement is relatively easy.

• Hammer Crusher: The main wear parts are the hammer heads, grates, and impact liners. The hammer heads wear fastest during operation and require regular rotation or replacement. Grate clogging or wear also affects output and production. It has a cost advantage when crushing materials of medium hardness and below, and those that are not highly abrasive.

Applicable Materials and Moisture Content Requirements

• Impact Crusher: More suitable for crushing materials of medium hardness and above, such as limestone, granite, and basalt. It is less sensitive to the moisture and clay content of the material, less prone to clogging, and has stronger adaptability.

• Hammer Crusher: More suitable for crushing materials of low to medium hardness and low abrasiveness, such as limestone, marl, and coal. It is very sensitive to moisture and stickiness; when the material's moisture content exceeds 12% or contains a large amount of clay, it is very easy to cause grate clogging, leading to a sharp decrease in output or even shutdown.

The Experienced Choice from a Mobile Crushing Plant Manufacturer

In the integration of mobile crushing equipment, we flexibly configure solutions based on our customers' specific working conditions:

• When customers require high-quality finished aggregates, and the material is hard and has a complex composition, we recommend mobile impact crushers. Their excellent particle shape and adjustability provide customers with higher product value.

• When customers are processing pure limestone or construction waste bricks, primarily to obtain mixed aggregates or backfill materials, and the particle shape requirements are not stringent, mobile hammer crushers are the economical choice due to their simple structure and low investment cost.

In summary, impact crushers are the choice for those seeking high quality, versatility, and strong adaptability; while hammer crushers are the solution for specific soft materials, focusing on simple and economical production. Twenty years of experience have taught us that there is no single best equipment, only the most suitable configuration.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.