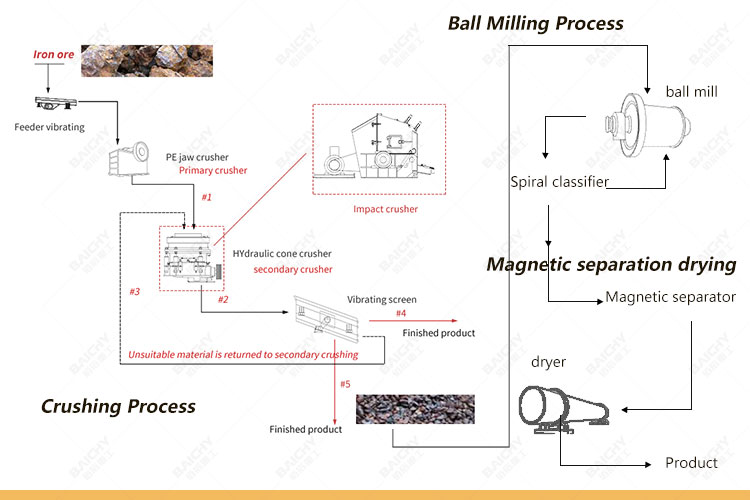

1. Process flow of Iron Ore crushing plant

Crushing and screening: The iron ore is initially crushed by jaw crusher, cone crusher, and other equipment, and the crushed ore is screened according to particle size using equipment such as vibrating screen.

Grinding and classification: The screened ore is sent to the ball mill for grinding, and the iron minerals in the ore are dissociated into monomers through grinding. Then use spiral classifier and other equipment to classify the grinding slurry to obtain the required slurry concentration and particle size.

Mineral sorting: According to the properties of iron ore, magnetic separation, flotation, gravity separation, and other methods are used to sort the slurry to obtain high-grade iron concentrate. Magnetic separation is mainly used to process weakly magnetic iron ore, while flotation is suitable for processing fine-grained iron ore.

Roasting reduction: For some difficult-to-separate iron ores, such as siderite, roasting reduction treatment is required to convert the iron minerals in the iron ore into a form that is easy to sort.

Filtration and dehydration: Filter and dehydrate the sorted iron ore concentrate to reduce the moisture content in the concentrate and facilitate subsequent processing.

2. Equipment selection of Iron Ore crushing plant

• Crushing equipment: jaw crusher, cone crusher

• Screening equipment: vibrating screen

• Grinding equipment: ball mill

• Grading equipment: spiral classifier

• Magnetic separation equipment: magnetic separator

• Flotation equipment: flotation machine

• Roasting equipment: rotary kiln

• Filtration and dehydration equipment: filter press

3. Environmental Management

During the processing of iron ore, wastewater, waste gas, waste residue, and other pollutants will be produced, which will have a certain impact on the environment. Therefore, it is necessary to strengthen environmental management, adopt sustainable development models such as clean production and circular economy, reduce pollutant emissions, and protect the ecological environment.

4. Cost Control

In the iron ore processing process, cost control is an important aspect. Costs can be reduced by strictly controlling raw material costs, improving production efficiency, and reducing energy consumption. At the same time, equipment management and maintenance are strengthened to ensure the normal operation of production equipment, reduce downtime, and improve production efficiency.

5. Technological innovation

With the continuous advancement of science and technology, iron ore processing technology is also constantly innovating. The technical level of equipment can be improved, energy consumption can be reduced, production efficiency can be improved, and costs can be reduced by introducing advanced technology, carrying out technological transformation and updating. At the same time, we will strengthen research and development efforts and develop new iron ore processing technologies and equipment to meet market demand and improve corporate competitiveness.

To sum up, iron ore processing solutions need to comprehensively consider aspects such as process flow, equipment selection, environmental management, cost control and technological innovation. By continuously optimizing and improving solutions, iron ore processing efficiency and quality can be improved, production costs can be reduced, and the development of related industries can be promoted.