120 t/h Limestone Crushing and Screening Production Line Core Equipment

In the current market for sand, gravel aggregates, and building materials, limestone has become one of the most mainstream processing raw materials due to its wide distribution, moderate hardness, and ease of crushing. A production capacity of 120 tons/hour is precisely the golden piding line between medium-to-large production lines and small-scale operations. It can meet the stable supply needs of regional commercial concrete plants and large-scale engineering construction projects, while avoiding the problems of excessive investment and idle capacity. Therefore, the theme of Jaw Crusher - 120 tons/hour Limestone Crushing and Screening Equipment accurately targets the core needs of many mining investors.

| Key Words | Limestone Crushing & Screening Plant |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤500mm |

| Motor Power | 55kw |

| Capacity | 90-180t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Equipment Overview: The Heart of the System – The Jaw Crusher

As the primary crushing pioneer in mining crushing equipment production lines, the stability and efficiency of the jaw crusher directly determine the capacity foundation of the entire production line. For a limestone processing capacity of 120 tons/hour, we recommend using a jaw crusher with a feed opening size of 750×1060mm or 900×1200mm. Its powerful crushing force and highly wear-resistant jaw plate design can easily crush large pieces of limestone to a medium size in one pass, preparing it for subsequent secondary and fine crushing processes.

Core Advantages of the Solution: Excellent Performance Forged by 20 Years of Experience

As a mining crushing equipment manufacturer with 20 years of experience, we understand that stability, efficiency, and low consumption are key to customer profitability. The advantages of our solution are:

1. High Reliability Design: The main structure of the equipment is reinforced, and the bearing specifications are upgraded, ensuring trouble-free operation under continuous high-load conditions.

2. Excellent Crushing Efficiency: The deep cavity crushing design and reasonable tooth angle not only meet the production capacity but also effectively reduce the content of flaky and elongated particles in the product, improving the quality of the finished material.

3. Lower Operating Costs: Modularly designed wear parts are easier to replace, extending their service life by more than 30%, significantly reducing the cost per ton of production.

4. Intelligent Control and Environmental Protection: The production line can integrate an automated control system for one-button start-stop and online monitoring. It is also equipped with comprehensive dust control and noise reduction solutions to meet environmental protection requirements. Success Story:

120 t/h Limestone Crushing and Screening Production Line Core Equipment | Jaw Crusher

A Large Cement Raw Material Base Project

In 2022, we provided a complete limestone crushing and screening solution for a large cement group in East China. The core requirement was a limestone raw material production capacity of 120 tons per hour.

• Raw material: Natural limestone with a particle size of ≤700mm

• Finished products: Three aggregate sizes: 0-5mm, 5-10mm, and 10-30mm

• Core process: Feeder → Jaw crusher (PE-900×1200) → Conveyor → Cone crusher (medium crushing) → Vibrating screen (screening) → Shaping machine (fine crushing and sand making) → Finished product silo.

• Project results: Since commissioning, the entire line has operated smoothly. The jaw crusher, as the core of the primary crushing process, has not experienced any major failures. The actual production capacity is stable at 125-130 tons/hour, exceeding customer expectations and receiving high praise from the client.

Related Equipment Recommendation: Complete Production Line Configuration

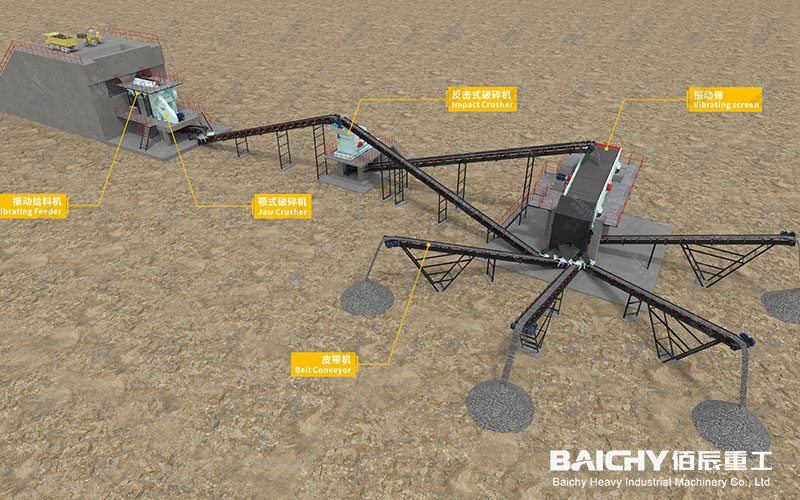

A high-efficiency crushing and screening system is not just a single machine. We provide turnkey solutions for our customers, and the key equipment配套 with the core jaw crusher includes:

• Feeding equipment: Heavy-duty plate feeder to ensure uniform and stable feeding.

• Medium and fine crushing equipment: Single-cylinder or multi-cylinder hydraulic cone crusher for medium and fine crushing, producing high-quality aggregate.

• Screening equipment: Multi-layer heavy-duty circular vibrating screen for efficient and precise particle size classification.

• Conveying and dust removal system: Belt conveyors, dust collectors, and other auxiliary equipment to form a closed loop.

Frequently Asked Questions (FAQ)

Q1: What is the approximate investment required for a 120-ton/hour production line?

A1: The investment depends on the specific equipment selection, degree of automation, and environmental standards. Typically, it's a medium-sized production line, and we offer various configuration options ranging from hundreds of thousands to millions of RMB, depending on the customer's needs and budget.

Q2: When processing limestone, does the jaw plate wear out quickly? Is replacement difficult?

A2: Limestone is a medium-to-low hardness material, so the wear on the jaw plates is relatively small. Our jaw crusher features a symmetrical design, allowing for reversal of the jaw plates when one end wears out, effectively doubling its lifespan. Additionally, the jaw plates are secured with hydraulic nuts, making replacement very convenient and typically completed within 1-2 hours.

Q3: How long does the installation and commissioning of the entire production line take?

A3: Assuming the foundation is already prepared, the installation of the main equipment takes approximately 15-20 working days. This is followed by 7-10 days of integrated commissioning and trial operation with materials. We provide full technical guidance throughout the process.

Q4: What is the equipment's energy consumption?

A4: The core crushing equipment uses national standard high-efficiency motors, and the entire line is designed with energy efficiency in mind. For a limestone production line with a capacity of 120 tons per hour, the total power configuration is typically between 400-500 kW. The specific energy consumption per ton needs to be calculated based on the final product particle size requirements.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.