About Jaw Crusher

Jaw crusher, also known as jaw crusher, is a kind of crushing equipment widely used in industry and mining. It is mainly used to crush various hard rocks, ores, metal materials, etc. into smaller particles or powders. The following is a detailed introduction to jaw crusher:

Working principle of jaw crusher

The working principle of the jaw crusher is mainly to use the relative movement between the movable jaw plate and the fixed jaw plate to crush the material. The specific process is as follows:

• Motor drive: The motor drives the eccentric shaft to rotate through the belt and pulley.

• Rotation of eccentric shaft: The rotation of eccentric shaft makes the movable jaw plate connected to it move up and down periodically with the eccentric shaft as the center.

• Movement of jaw plate: The movable jaw plate is connected to the eccentric shaft through the connecting rod. When it moves up and down, it makes the movable jaw plate approach or leave the fixed jaw plate.

• Material crushing: When the movable jaw plate approaches the fixed jaw plate, the material is clamped between the two jaw plates and is subjected to pressure and shear force, so it is crushed.

• Discharge: The crushed material is discharged through the discharge port at the bottom of the crushing chamber.

Types of jaw crushers

1. PE jaw crusher: a traditional jaw crushing equipment with a large feed opening and uniform discharge. The production capacity ranges from 50-1000t/h, the maximum feed size can reach less than 1200mm, and the discharge adjustment range is 10-500mm.

2. European jaw crusher (C series jaw crusher): supplementary equipment for ordinary jaw crushers, with finer processing fineness, suitable for small production needs. The production capacity ranges from 50-650t/h, the feed size is between 400-1200mm, and the discharge range is 20-300mm.

3. High-energy jaw crusher (HJ jaw crusher): relatively higher production capacity, large crushing ratio, and high wear resistance. The production capacity ranges from 50-1100t/h, and the feed particle size is also below 1200mm, but the feed particle size is larger than that of the PE version jaw crusher with the same capacity, and the discharge range is also 20-300mm.

4. Mobile jaw crusher: It adopts tire or crawler-type movement, with the characteristics of strong mobility, convenient transportation, intelligent operation, small footprint, and low investment cost. Its production capacity ranges from 50-650t/h, and the feed and discharge particle size depends on the equipped jaw crusher.

Performance characteristics of jaw crusher

• Deep crushing chamber and no dead zone: improves feed capacity and output.

• Large crushing ratio: uniform product particle size.

• Gasket-type discharge port adjustment device: reliable and convenient, with a large adjustment range, which increases the flexibility of the equipment.

• Safe and reliable lubrication system: easy replacement of parts and small maintenance workload.

• Simple structure: reliable operation and low operating costs.

• Equipment energy saving: single machine energy saving 15% to 30%, system energy saving more than double.

• Low noise, less dust: meet environmental protection requirements.

Uses of jaw crusher

• Mining: crush various hard ores and rocks into particles of appropriate size to provide raw materials for subsequent mineral processing and smelting.

• Construction: used in the production of building materials, such as crushing limestone, granite, etc. into concrete, mortar, etc., and can also crush construction waste into recyclable materials.

• Road engineering: crush various stones, such as limestone, basalt, etc., for roadbed and pavement paving of highways, railways, and other road projects.

• Chemical industry: crush various chemical raw materials, such as coal, sulfur, phosphate rock, etc., to provide raw materials for chemical production.

• Environmental protection: crush urban garbage, scrap iron, and other waste into smaller particles, which is convenient for garbage disposal and resource recycling.

Daily inspection and maintenance of jaw crusher''

In order to ensure the normal operation of the jaw crusher and extend its service life, regular inspection and maintenance are required, including:

• Check the working condition of the crusher: Regularly check whether the jaw plate, vibrator, bearing and other parts are worn or loose.

• Check the conveyor belt: Check whether the conveyor belt is cracked or damaged, and check whether the conveyor belt tension is appropriate.

• Clean the inside of the crusher: Regularly clean the debris inside the crusher to avoid affecting the normal operation of the crusher.

• Replace lubricating oil and grease: Ensure the lubrication of bearings, gears, and other parts.

• Maintain equipment: Including cleaning equipment, replacing worn parts, etc.

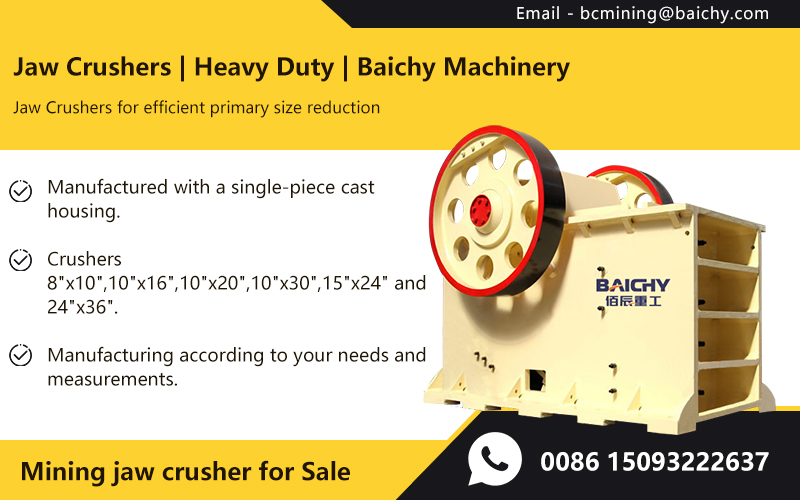

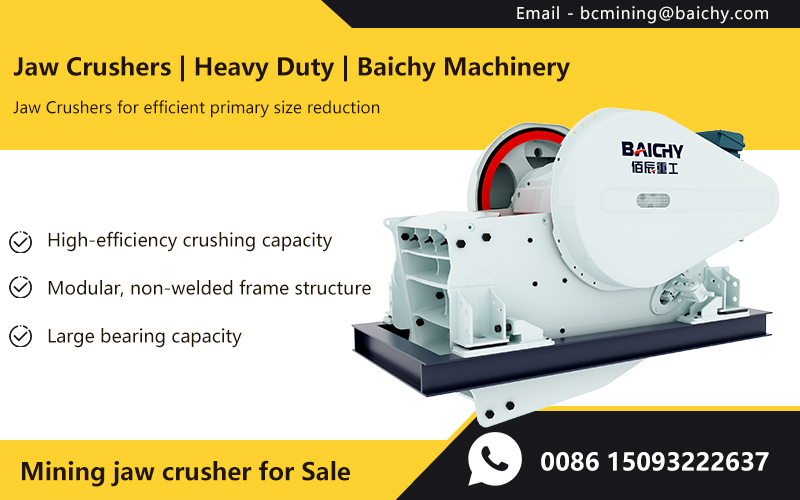

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.