Advanced manufacturing technology of semi-autogenous grinding mill: an industry breakthrough of high-efficiency energy saving and innovative design

In the mining, metallurgy, building materials and other industries, semi-autogenous grinding mills are key crushing equipment that directly affects production efficiency and energy consumption levels. With the advancement of technology, the new generation of semi-autogenous grinding mill manufacturing technology has significantly improved equipment performance and stability through high-efficiency energy-saving design, intelligent control system and innovative structural optimization. This article will deeply analyze the advanced manufacturing technology of semi-autogenous grinding mills and explore how it can help companies reduce operating costs and increase production capacity.

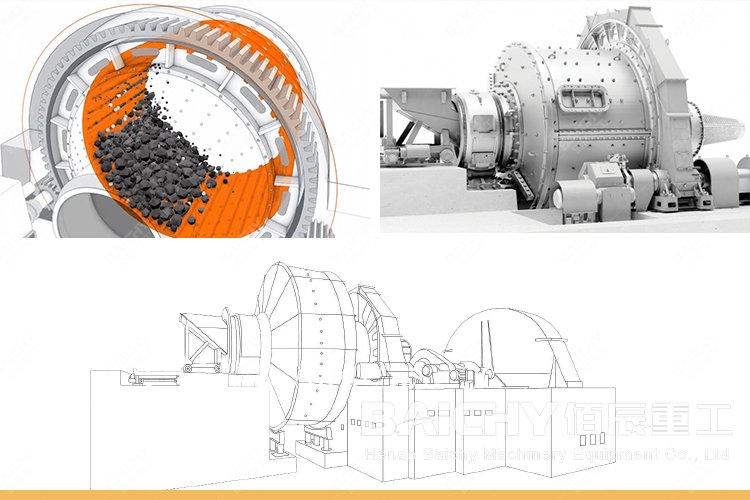

1. Core advantages of semi-autogenous grinding mills

1.1 High efficiency and energy saving, reducing operating costs

Traditional grinding mills have high energy consumption and fast wear, while modern semi-autogenous grinding mills use variable frequency drive technology and optimized grinding trajectory design to reduce energy consumption by 20%-30%. Through the intelligent load regulation system, the equipment can automatically adjust the speed according to the hardness of the ore to avoid energy waste.

1.2 Processing capacity increased by more than 30%

The new generation of SAG mills has significantly increased the processing capacity by adopting large-diameter cylinder design and high-strength wear-resistant materials, which is suitable for large mines and high-yield production lines. For example, after a certain iron ore project adopted a new SAG mill, the daily processing capacity increased from 5,000 tons to 6,500 tons.

1.3 Intelligent control system to reduce manual intervention

• Automated monitoring: Real-time monitoring of bearing temperature and vibration data to prevent failures.

• Remote operation and maintenance: Support cloud data management, engineers can remotely diagnose and optimize parameters.

• AI predictive maintenance: Through big data analysis, early warning of the need to replace worn parts.

2. Key technologies for manufacturing SAG mills

2.1 High-strength wear-resistant materials

The use of composite alloy liners and ceramic-metal mixed grinding media greatly extends the service life and reduces the maintenance frequency.

2.2 Optimized structural design

Dual motor drive: ensure power balance, reduce vibration and wear.

Dynamic airflow control: improve grinding efficiency and reduce over-crushing.

2.3 Green environmental protection technology

Low noise design: meet environmental protection standards and suitable for mining areas around cities.

Dust recovery system: reduce emissions and improve resource utilization.

3. Application case: Successful practice of semi-autogenous grinding mill in the mining industry

Case 1: A large copper mine project

Challenge: The original equipment has high energy consumption and insufficient processing capacity.

Solution: Use a new energy-saving semi-autogenous grinding mill with an intelligent control system.

Effect: Energy consumption is reduced by 25%, and annual electricity bills are saved by more than 3 million yuan.

Case 2: Iron ore tailings treatment

Challenge: Traditional mills wear quickly and have high maintenance costs.

Solution: Upgrade to a wear-resistant composite liner semi-autogenous grinding mill.

Effects: Liner life extended by 50%, annual maintenance costs reduced by 40%.

4. Future trends: intelligence and automation of SAG mills

With the development of Industry 4.0 and digital twin technology, SAG mills in the future will achieve:

✔ Fully automatic unmanned operation

✔ AI dynamically optimizes grinding parameters

✔ Blockchain traceability to ensure equipment data transparency

The advancement of SAG mill manufacturing technology is driving the mining, metallurgy and other industries to develop in the direction of high efficiency, energy saving and intelligence. Choosing advanced SAG mills can not only increase production capacity, but also significantly reduce operating costs.

Contact us to obtain customized SAG mill solutions to help your company achieve technological upgrades!