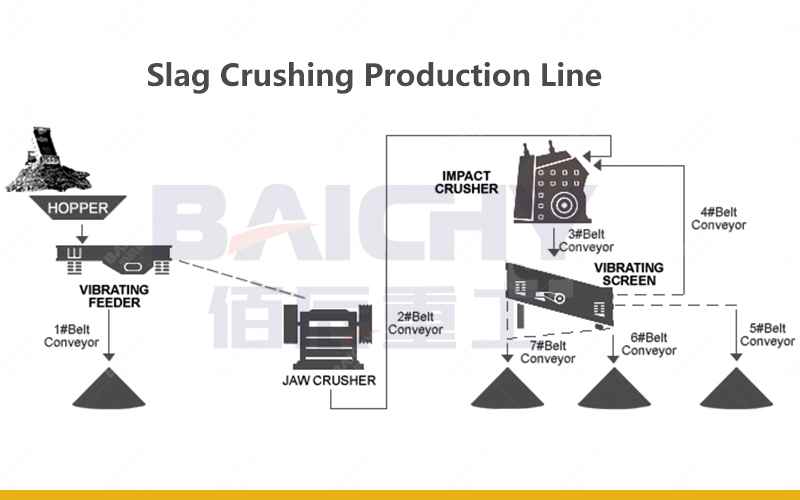

Slag crushing production line is an industrial process for handling slag, which mainly includes a series of equipment and steps to crush, screen and convert slag into materials that can be used in other industrial processes. The following is a detailed description of the slag crushing production line:

Production line composition of slag crushing production line

Feeding equipment: such as vibrating feeder, used to evenly and continuously transport slag from the silo to the crushing equipment.

Crushing equipment of slag crushing production line

1. Jaw crusher: It consists of two jaw plates and crushes materials by simulating the movement of animal jaws. This equipment is widely used in crushing operations of various ores and bulk materials.

2. Impact crusher: It is mainly used to process materials that need to be moved frequently, such as raw materials in metallurgy, chemical industry, building materials, and other industries.

3. Vertical crusher: Vertical crushers may also be used in some production lines, such as vertical compound crushers, for further crushing of slag.

4. Screening equipment: such as a vibrating screen, used to screen the crushed materials and separate products of different particle sizes.

5. Conveying equipment: such as belt conveyors, chain conveyors, etc., used to transport materials in the production line.

6. Dust removal equipment: such as pulse dust collectors, is used to collect dust generated during the crushing process to ensure the cleanliness of the production environment.

Working principle of slag crushing production line

• Slag first enters the crushing equipment through the feeding equipment and is crushed into smaller particles after being crushed by equipment such as jaw crushers and impact crushers.

• The crushed material is screened by screening equipment to obtain products of different particle sizes.

• The screened material is transported to the next process through conveying equipment, or output as the final product.

• The dust generated during the crushing process is collected and processed by dust removal equipment.