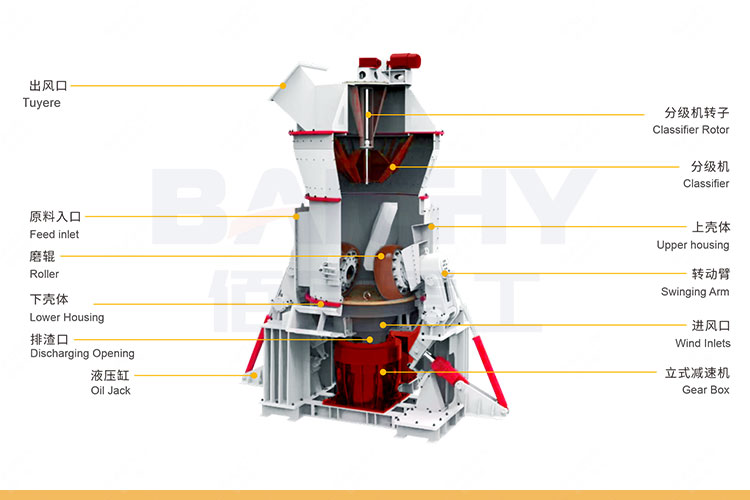

The main function of the coal mill (vertical roller mill)in clinker production is to crush and grind coal blocks into pulverized coal to meet the combustion needs in clinker production. The following is the specific role of coal mill in clinker production:

Improve combustion efficiency: The particle size of the pulverized coal after grinding through the coal mill is finer and more uniform, which helps to improve the combustion speed and combustion efficiency of the pulverized coal. In the clinker production process, pulverized coal is an important fuel, and its combustion efficiency directly affects the quality and output of clinker.

Reduce the production of pollutants: After the coal mill grinds the coal into pulverized coal, the pulverized coal can burn more completely during combustion, reducing the production of unburned coal and cinders, thus reducing pollutants such as sulfur dioxide and nitrogen oxides. etc. emissions, which is conducive to environmental protection and sustainable development.

Control the particle size of pulverized coal: The coal mill can control the particle size of pulverized coal within a certain range by adjusting parameters such as grinding pressure and screening devices according to the requirements of clinker production for pulverized coal particle size. This helps ensure the stability and efficiency of combustion and also facilitates control and adjustment during subsequent clinker production.

Improve the degree of automation: Modern coal mills are usually equipped with automated control systems that can achieve functions such as remote control and automatic detection. This helps reduce the labor intensity of operators and improves production efficiency and safety. In the clinker production process, the automated control of the coal mill can be coordinated with the entire production process to achieve more efficient production and management.

In short, the coal mill plays an important role in clinker production. It provides strong support and support for clinker production by improving the combustion efficiency of pulverized coal, reducing the generation of pollutants, controlling the particle size of pulverized coal, and improving the degree of automation. Assure.