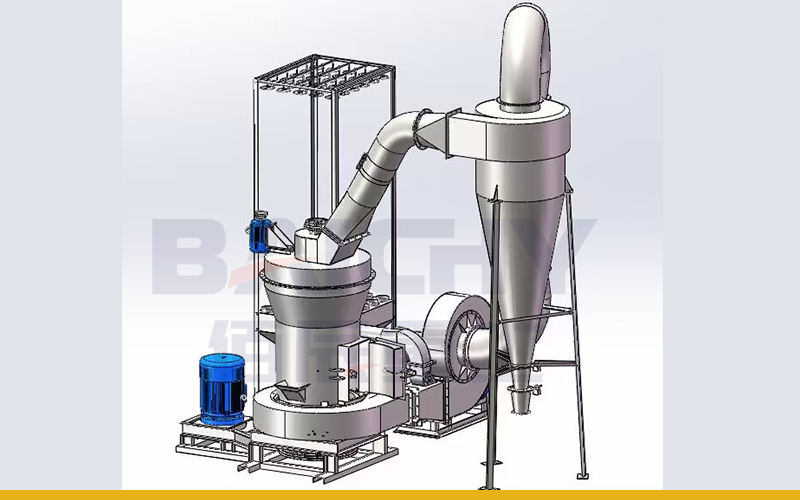

Mineral Vertical Grinding Equipment

What is the working principle of a Vertical Roller Mill (VRM)?

As a mining equipment manufacturer with 20 years of experience, we understand the importance of efficient and energy-saving grinding technology for mining operations. Among numerous grinding equipment options, the vertical roller mill has become one of the core pieces of equipment in modern mining plants due to its excellent performance. This article will delve into the working principle and advantages of VRM, providing you with a comprehensive technical perspective based on practical applications.

Working principle of grinding equipment

In-depth Analysis of VRM Working Principle

The vertical roller mill, as the name suggests, has a core structure consisting of vertically arranged grinding rollers and a grinding table. It grinds materials through a crushing principle rather than an impact principle, representing a revolution in efficiency.

Core Working Process

The VRM working process can be summarized as an integrated feeding-crushing-drying-classification-collection process.

1. Feeding and Distribution: Raw materials are fed into the mill through an airlock feeding device and fall onto the center of the rotating grinding table. Under the action of centrifugal force, the material is evenly distributed to the grinding area at the edge of the grinding table.

2. Crushing and Grinding: 2-4 grinding rollers, driven by a hydraulic system, crush the material layer on the grinding table. The material is crushed and ground between the rollers and the grinding table. This is the core of the VRM working principle, which utilizes immense pressure to create cracks in the material and crush it, resulting in significantly lower energy consumption compared to the collision and friction of traditional ball mills.

3. Drying and Conveying: While grinding, hot air (from kiln exhaust gas or a hot air furnace) is introduced from the bottom of the mill and passes through the material layer. The hot air simultaneously dries the wet raw materials and blows the finely ground material upwards to the classifier at the top.

4. Classification and Collection: The rising airflow carries the material particles into the high-efficiency dynamic classifier at the top. Coarse particles are separated and fall back onto the grinding table for re-grinding (internal circulation), while fine powder meeting the required fineness is discharged from the mill with the airflow and collected as finished product by the downstream bag filter.

Essential Differences from Ball Mills

Understanding the working principle of VRM is key to comparing it with traditional ball mills. Ball mills use a combination of impact and friction, with steel balls randomly colliding with the material, resulting in low energy efficiency. VRMs, on the other hand, utilize material bed grinding, where material particles are crushed against each other under pressure. The energy is directly applied to the grinding process, and the integrated high-efficiency classification system prevents over-grinding, resulting in significant energy savings.

Outstanding Advantages of VRM in the Mineral Processing Industry

Based on its unique working principle, VRM demonstrates significant advantages in mineral processing plant construction.

• Extremely low energy consumption: Grinding energy consumption is 30%-50% lower than traditional ball mills, representing the biggest operational cost advantage.

• Powerful drying capacity: Can handle materials with moisture content as high as 15%-20%, eliminating the need for separate drying equipment and simplifying the process.

• Small footprint: The compact vertical structure occupies only 50%-70% of the area required by a ball mill system, resulting in lower infrastructure costs.

• Low noise and dust: The fully enclosed system provides a more environmentally friendly working environment and meets environmental protection requirements.

• Easy adjustment and stable product fineness: The fineness of the finished product can be quickly and flexibly controlled by adjusting the classifier speed and grinding roller pressure.

Successful Application Cases

In a large iron ore processing plant renovation project, we replaced the original two-stage ball mill system with a VRM-3400 for the regrinding of iron concentrate.

• Results: System power consumption decreased by more than 40%, and the product particle size (-400 mesh) pass rate increased steadily from 88% to over 95%. Furthermore, the plant successfully utilized waste heat to dry the filter cake moisture, saving millions of yuan annually. This fully validates the efficiency and economic benefits of the VRM working principle.

How to Choose the Right VRM for Your Mineral Processing Plant?

The following key points should be considered when choosing a VRM:

1. Material characteristics: Hardness, abrasiveness, particle size, and moisture content are primary factors.

2. Production capacity and fineness requirements: Determine the design output and target product particle size distribution.

3. System configuration: Whether drying, hot air furnaces, or special wear-resistant treatments are required. 4. Manufacturer Experience: Choosing a manufacturer with extensive industry experience and a proven track record (such as ourselves) ensures reasonable process design and reliable equipment operation.

Frequently Asked Questions about VRM (FAQ)

Q1: How well does VRM adapt to material hardness?

A: Modern VRMs, through optimized roller pressure and wear-resistant material technology, can effectively handle medium to high-hardness ores (such as iron ore, gold ore, and copper ore). For extremely hard materials, detailed ore grindability tests are required, and wear resistance treatment needs to be strengthened in the design.

Q2: Is VRM maintenance complex? Are repair costs high?

A: The modular design of VRM makes maintenance relatively convenient. Core wear parts (such as roller liners and grinding disc liners) use hardfacing repair technology, which can be repaired online or offline, significantly reducing spare parts costs. Regular planned maintenance is key, and the total maintenance cost is usually lower than that of a ball mill system with equivalent capacity.

Q3: Can VRM be used for coarse grinding or primary grinding of metal ores?

A: Traditionally, VRM has been used more for fine grinding. However, with the increase in equipment size and technological advancements, VRM is now successfully applied to coarse grinding and primary grinding of many metal ores, especially in energy-efficient grinding systems combining pre-crushing + VRM with high-pressure grinding rolls, demonstrating great potential.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.