|

Equipment |

ZSW1100x4200 Vibrating feeder | PE750x1060 Jaw crusher | PFW1320 impact crusher | Vibrating screen | Belt conveyor. |

|

Raw materials |

It is suitable for processing various materials such as granite, limestone, basalt, etc., improving production efficiency and finished product quality. |

|

Feed Size |

Less than 425mm |

|

Capacity |

150-200t/h |

|

Finished product |

Adjustable, common sizes are 0-5mm (machine-made sand), 5-10mm, 10-20mm, 20-40mm, etc. |

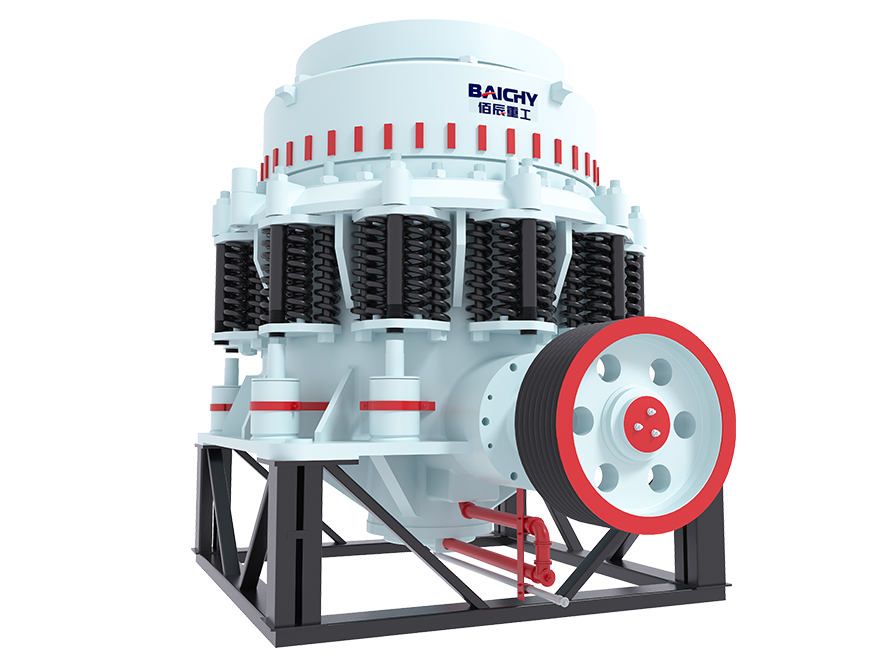

CS Symons cone crusher is a high-performance cone crusher. It is a modern high-performance crusher designed and developed based on the principle of laminated crushing and the concept of more crushing and less grinding, based on the introduction and absorption of foreign technology, according to customer needs.

In industrial production, belt conveyors can be used as the link between production machinery and equipment to form continuous production, so as to realize the continuity and automation of production links, improve productivity and reduce labor intensity.

The belt conveyor can be widely used in mining, metallurgy, coal, transportation, hydropower, and other departments to transport bulk materials or finished items.

Vibrating feeder → jaw crusher (coarse crushing) → impact crusher (medium crushing) → circular vibrating screen (grading) → finished product (0-5mm, 5-10mm, 10-30mm)

Features: low investment, low energy consumption, suitable for limestone, bluestone, and other medium and low hardness materials.

Vibrating feeder → jaw crusher (coarse crushing) → cone crusher (medium crushing) → impact crusher (sand making) → circular vibrating screen (closed loop)

Features: The finished product has excellent particle shape (needle-shaped ≤8%), suitable for sand making of high hardness materials such as granite and basalt.

Total crushing ratio: ≤40 (coarse crushing: medium crushing: fine crushing ≈ 4:3:3)

Discharge port adjustment: jaw crusher (80-150mm), cone crusher (25-50mm), sand making machine (3-10mm)

Screening closed loop: ≤150% (controlled by adjusting the screen size)

Conventional stone: 0-5mm (sand), 5-10mm, 10-20mm, 20-31.5mm

Sand and gravel mixture: powder content ≤10% (wheel sand washing machine is required)

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.