Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

| Model | PE750x1060 |

|---|---|

| Feeder Opening Size(mm) | 750x1060 |

| Max. Feeding Size(mm) | 630 |

| Outlet adjusting Size(mm) | 60-150 |

| Motor Power(kw) | 110 |

| Capacity(t/h) | 110-380 |

| Overall Dimension(mm) | 2630x2310x3110 |

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | - | 1 |

| 2 | Vibrating feeder | ZSW1142 | 1 |

| 3 | Jaw Crusher | PE1200x1500 | 1 |

| 4 | Cone Crusher | HPC300 | 1 |

| 5 | Vibrating Screen | 2YK2470 | 1 |

| 6 | B1000 | 20m | 2 |

| 7 | B800 | 20m | 3 |

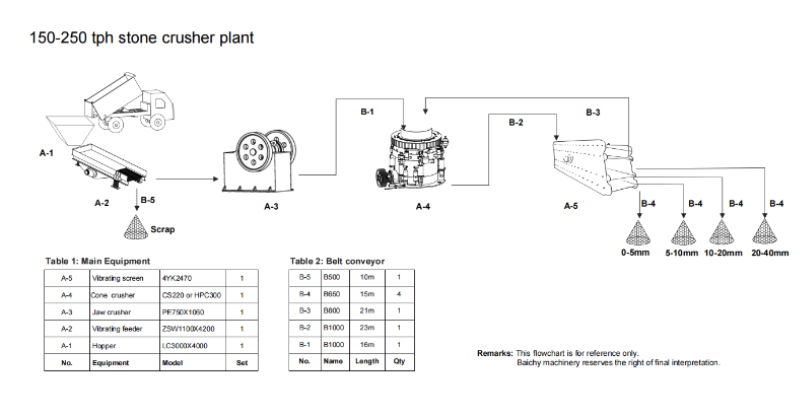

The 150 t/h crushing production line is an efficient and modular stone processing system designed for medium and large mines, quarries, and construction aggregate production. This production line adopts the core configuration of PE 750×1060 jaw crusher + HP300 cone crusher, which can efficiently process various materials such as granite, basalt, limestone, etc. The finished product particle size is adjustable to meet different engineering needs.

1. Vibrating feeder - uniform feeding guarantee: heavy-duty trough design, strong wear resistance, variable frequency adjustment of feeding amount, matching crusher capacity;

2. Primary crushing: PE 750×1060 jaw crusher: high-strength frame, hydraulic adjustment device, double wedge adjustment system;

3. Secondary crushing: HP300 cone crusher, medium and high hardness ore (granite/basalt) crushing equipment, compared with the impact crusher, wear-resistant parts life increased by 3 times;

4. Screening system: 4YK2470 vibrating screen, multi-layer screen configuration (3-5 finished product specifications can be customized);

5. Intelligent conveying system: main conveyor belt width 800-1000mm, tear-resistant steel wire rope core, life of more than 5 years.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!