Silica sand, also known as silicon dioxide or quartz sand, is a refractory granular material with quartz as the main mineral component and a particle size of 0.020 mm~3.350 mm. According to different mining and processing methods, silica sand can be divided into artificial silica sand and natural silica sand such as washed sand, scrubbed sand, and selected (flotation) sand. Silica sand has the characteristics of hardness, wear resistance, and stable chemical properties. Its main mineral component is SiO₂, and its colors are various, including milky white, light yellow, brown, and gray.

Common specifications of silica sand are 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm, 10-20 mesh, 20-40 mesh, 40-80 mesh, 100-120 mesh, 200 mesh, 325 mesh.

Silica sand processing plant equipment is an indispensable and important part of the silica sand processing process. These equipment are mainly responsible for the crushing, screening, washing, drying, and other process links of silica sand to improve the purity and quality of silica sand.

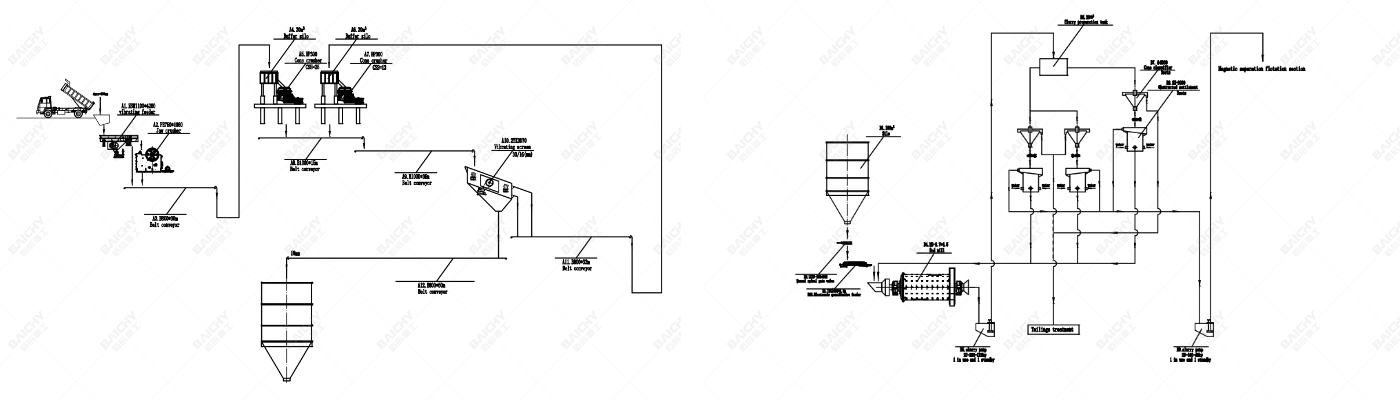

The Silica sand production process is a complex and delicate process designed to extract and process silica sand products that meet specific requirements from raw ore.

The raw materials enter the jaw crusher for coarse crushing, crushed into smaller particles, and enter the cone crusher for fine crushing. During the fine crushing process, secondary crushing may be required to meet the particle size requirements.

The particle size is screened into products of different particle sizes through multiple layers of screens. The qualified materials after screening enter the next process, and the unqualified materials are returned to the crusher for re-crushing.

Grinding: For silica sand that needs to be further improved in purity, grinding treatment is also required. Grinding usually uses equipment such as ball mills to further grind the materials to the required particle size.

Classification: The ground materials are classified by classification equipment (such as spiral classifiers, hydraulic classifiers, etc.) to separate the particle size grades that meet the requirements.

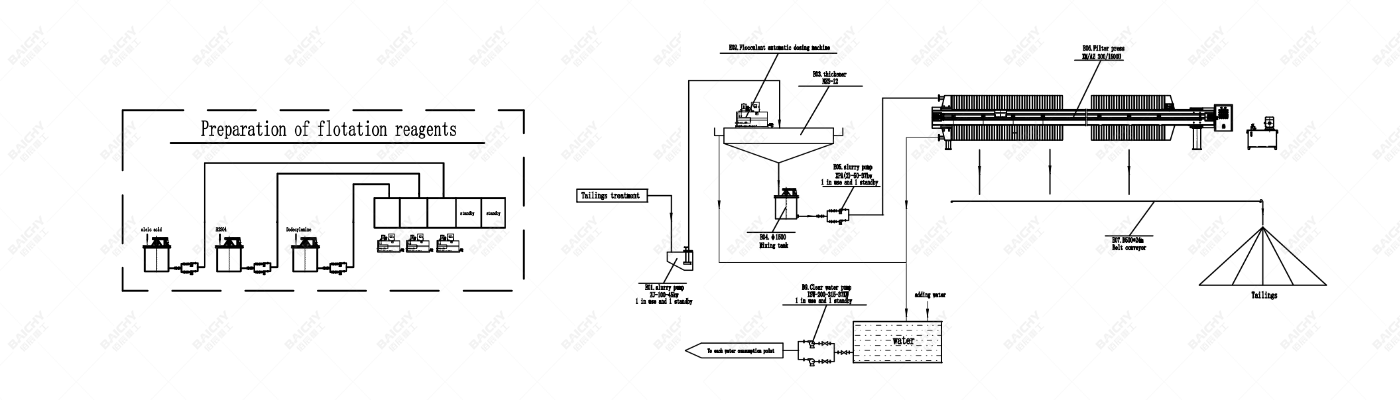

Function: Remove dirt, dust, and other impurities on the surface of silica sand to improve the cleanliness of silica sand.

Common equipment: spiral sand washer, bucket sand washer, drum sand washer, etc. This equipment cleans the impurities on the surface of silica sand through the action of hydraulic and mechanical forces.

Function: Dry the dehydrated silica sand to further reduce its moisture content and improve the stability of the product.

Common equipment: rotary dryer, three-drum dryer, etc. Drying equipment has the characteristics of high drying efficiency, low energy consumption, and easy operation.

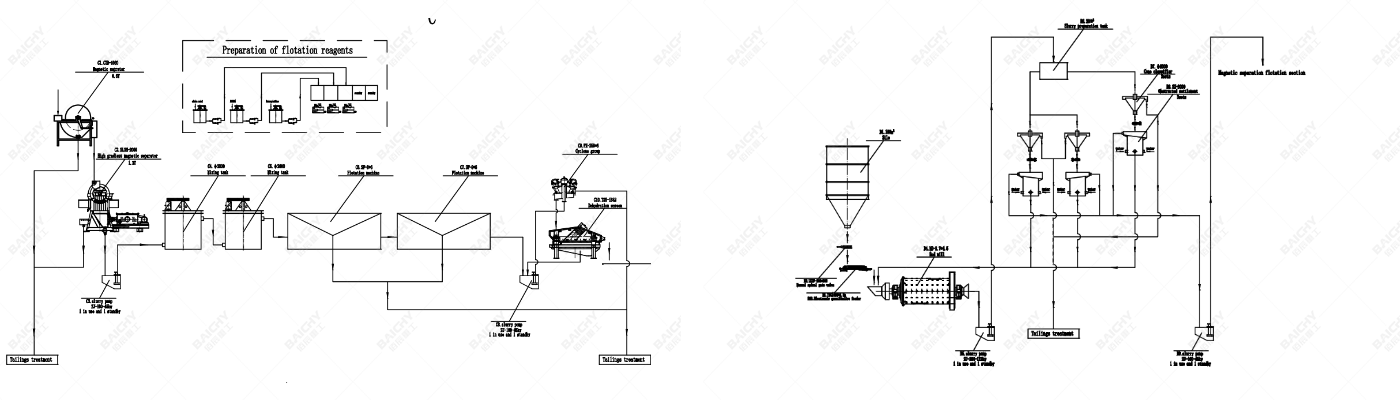

Function: Remove magnetic impurities such as iron in silica sand.

Common equipment: strong magnetic separator, weak magnetic separator, etc. Magnetic separation equipment can effectively remove magnetic impurities in silica sand and improve the purity of the product.

Function: Remove non-magnetic associated minerals in silica sand through a flotation process.

Common equipment: flotation machine, mixing barrel, etc. Flotation equipment is widely used in the field of silica sand deep processing and can further improve the quality of products.

Silica sand, also known as quartz sand, is mainly composed of silicon dioxide and has a wide range of industrial uses. The following are the main uses of silica sand:

Silica sand is a key raw material for the manufacture of various glass products, including flat glass, float glass, special glass (such as insulating glass, vacuum glass, conductive glass, etc.) as well as glass instruments and daily utensils (such as glass cups, glasses, microwave turntables, mobile phone screens, etc.). The purity and chemical composition of silica sand directly affects the quality and performance of glass.

In ceramic production, silica sand, as an important component of blanks and glazes, can improve the whiteness and quality of ceramics, reduce drying time, prevent cracks and peeling, and make the ceramic surface more beautiful. In addition, silica sand can also be used to prepare enamel, which requires a high purity of silica sand.

Silica sand can be used as a raw material or additive for silicon metal, ferrosilicon alloy, and silicon aluminum alloy, and plays an important role in the metallurgical industry.

Silica sand is also widely used in the construction field. When building houses and roads, adding silica sand to concrete and cement can enhance their physical properties, make the ground and walls stronger, and prevent cracks.

Silica sand is used as a raw material for silicon compounds and water glass in the chemical industry and participates in various chemical reaction processes.

Silica sand can be used to improve the wear resistance and anti-aging properties of rubber products, and adding silica sand to plastics can improve their wear resistance.

In summary, silica sand plays an irreplaceable role in many industrial fields with its unique physical and chemical properties. With the advancement of science and technology and the development of industry, the application field of silica sand will continue to expand and deepen.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!