Main equipment for aggregate processing

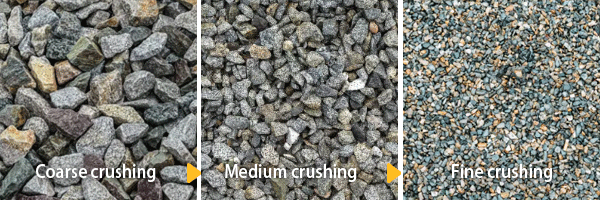

Crusher: equipment used to crush raw materials, including coarse crusher, medium crusher and fine crusher, etc.

Screening machine: equipment used to screen crushed aggregate, which can screen out aggregate products of different particle sizes.

Sand washer: equipment used to wash aggregate, which can remove impurities such as soil and stone powder on the surface of aggregate.

Dryer: equipment used to dry aggregate, usually used in occasions where moisture in aggregate needs to be removed.

Conveying equipment: including conveyor belts, telescopic conveyors, etc., used to transport aggregate from one location to another.

Application of aggregate processing

Aggregate processed products are widely used in engineering fields such as construction, roads, bridges, and water conservancy. As one of the main components of concrete, aggregate plays an important role in improving the durability and stability of concrete. At the same time, with the improvement of environmental awareness and the promotion of resource recycling, the application of artificial recycled aggregate and machine-made sand is becoming more and more extensive.