Main features of aggregate crusher

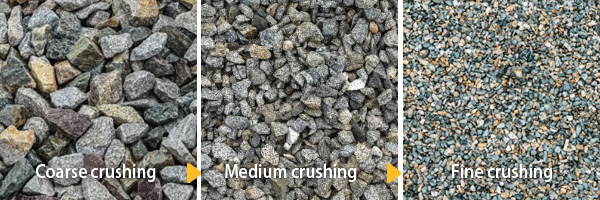

1. High efficiency: Aggregate crusher has efficient crushing capacity and can quickly crush stones into the required particle size.

2. Flexibility: Different types of aggregate crushers are suitable for different stone and particle size requirements, and can be selected according to actual needs.

3. Durability: Aggregate crushers usually use high-quality materials and advanced manufacturing processes, with high durability and service life.

4. High degree of automation: Modern aggregate crushers are usually equipped with advanced control systems and automation devices, which can realize remote monitoring and automatic control, improve production efficiency and safety.