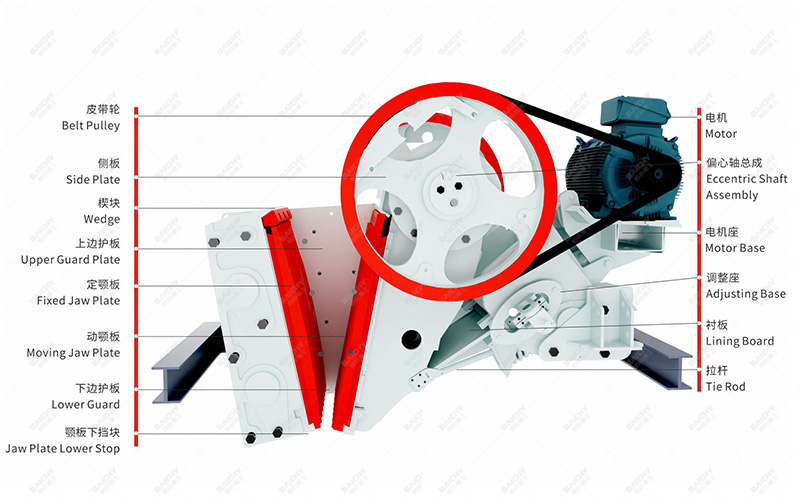

Structural features of jaw stone crusher

The jaw stone crusher is mainly composed of two jaw plates, a fixed jaw plate and a movable jaw plate (moving jaw), to form a crushing chamber, and completes the material crushing operation by simulating the movement of the two jaws of animals. Among them, the fixed jaw plate (fixed jaw) is fixed vertically (or the upper end is slightly tilted outward) on the front wall of the machine body, and the movable jaw plate is tilted to form a crushing chamber (working chamber) with a larger upper part and a smaller lower part with the fixed jaw plate. In addition, the movement of the jaw teeth is supported by an eccentric shaft, which runs through the machine body frame and is driven by a flywheel to produce eccentric movement.