When materials such as limestone enter the crushing chamber of the crusher, they are first hit by the hammers on the high-speed rotating rotor. The hammers impact the materials at high speed to cause their initial crushing. This impact causes the materials to be crushed into smaller particles.

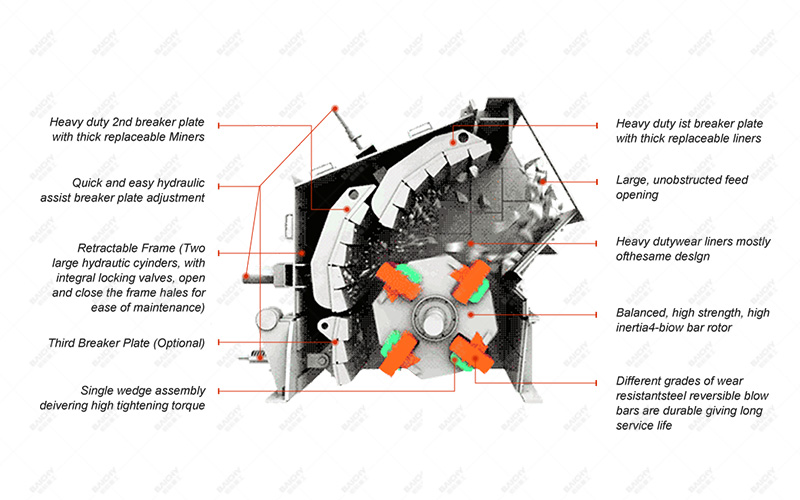

Subsequently, these initially crushed materials are thrown to the impact plate. The impact plate is a wear-resistant plate fixed to the crusher body, which plays a role in further crushing the materials. When the materials collide with the impact plate, they will be strongly rebounded and impacted, thereby achieving further crushing.

The crushed materials form a continuous cycle in the crushing chamber. They are constantly hit by the hammers, thrown to the impact plate, and then rebounded back, and this process is repeated until the desired crushing particle size is reached.

During the crushing process, the materials will also have mutual impact and friction, which also helps the crushing of the materials. In addition, the rotor of the crusher will also generate a certain centrifugal force during the rotation process, so that the materials are more evenly distributed and more fully crushed in the crushing chamber.

Finally, when the materials reach the desired crushing particle size, they will be discharged through the discharge port at the bottom of the crusher. The size of the discharge opening can be changed by adjusting the relevant components of the crusher to meet different crushing needs.