In response to the customer's 5-10tph (tons per hour) ultra-fine vertical mill how to grind quartz and silica to 10 microns, the SRM series vertical mill recommended by Baiqi is a good choice. The following is a detailed explanation of how the SRM series vertical mill meets this demand:

Ultra-fine vertical mill overview

The SRM series vertical mill is a high-efficiency equipment for grinding, energy saving and environmental protection, and is widely evaluated for grinding a variety of ores and stocks. Its overall structure is reasonable, the technology is advanced, the operation is stable and reliable, and the main technical and economic indicators have reached the international advanced level.

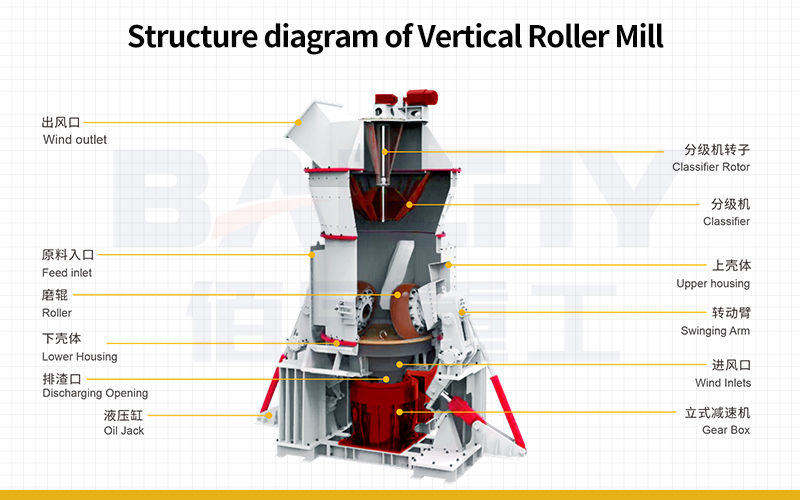

Ultra-fine vertical mill working principle

• The main motor drives the grinding disc to rotate through the load machine.

• Hot air enters the interior of the vertical mill from the air inlet.

• The discharge gradually reaches the center of the grinding disc through the feed inlet, and under the action of centrifugal force, the discharge moves evenly from the center of the grinding disc to the edge.

• When the material bin passes through the powder roller area on the grinding disc, it is crushed by the roller. The large-sized grinding material bin is directly crushed by the grinding and crushing, while the fine-grained material bin is squeezed and crushed between particles.

• The crushed material continues to move to the edge of the grinding disc until it is taken away by the strong end of the wind ring.

• In the discharge carried by the airflow, the larger particle hopper returns to the grinding disc for further crushing under its own gravity, and the remaining dischargers enter the high-efficiency dynamic separator with the airflow for powder separation.

Under the action of the blades of the high-efficiency dynamic separator, the material that does not meet the fineness requirements returns to the powder grinding disc for grinding, while the material that meets the fineness requirements enters the powder dust collector through the valve through the pipeline for collection, and is discharged through the discharge device as the finished powder.

Advantages of ultra-fine vertical mill

1. High grinding efficiency: The lamination grinding method of rolling, grinding and stacking on the grinding disc by the grinding roller has low friction, which saves 30%~40% of friction compared with the ball mill system.

2. Strong alarm capacity: The hot air directly contacts the alarm in the mill, and the alarm capacity is strong. The parallel mill system saves alarms, which saves both alarms and energy.

3. Adjustment flexibility: By adjusting the hot air temperature, it can easily cope with feeds of different humidity. At the same time, the equipment is equipped with a variable frequency speed regulation system, which can adjust the reach and output of the mill according to needs.

4. Uniform particle size of finished products: The high-efficiency dynamic separator ensures uniform particle size distribution of finished products, and the fineness is easier to adjust.

5. Low noise and low pollution: The equipment has low noise, and the emission concentration of the grinding products is lower than the environmental protection requirements after emission reduction.

Ultrafine vertical mill meets customer needs

1. Processing capacity: The processing capacity of the SRM series vertical mill is 5-10tph (tons/hour), completing 1. Fully meet the production needs of customers.

2. Grinding fineness: The equipment can grind quartz and silica to a finer particle size of 10 microns to ensure product quality.

3. Energy saving and environmental protection: The equipment has low noise and low pollution during operation, which meets the national environmental protection requirements.

Service and Support

As a professional grinding mill manufacturer, Baichy will provide customers with a full range of services and support, including equipment installation and commissioning, operation training, maintenance and after-sales technical support.

SRM series vertical grinding mills are fully capable of meeting customers' production needs of grinding quartz and silica to 10 microns with their advantages of energy saving, environmental protection, flexible adjustment and efficient completion of uniform roughness.