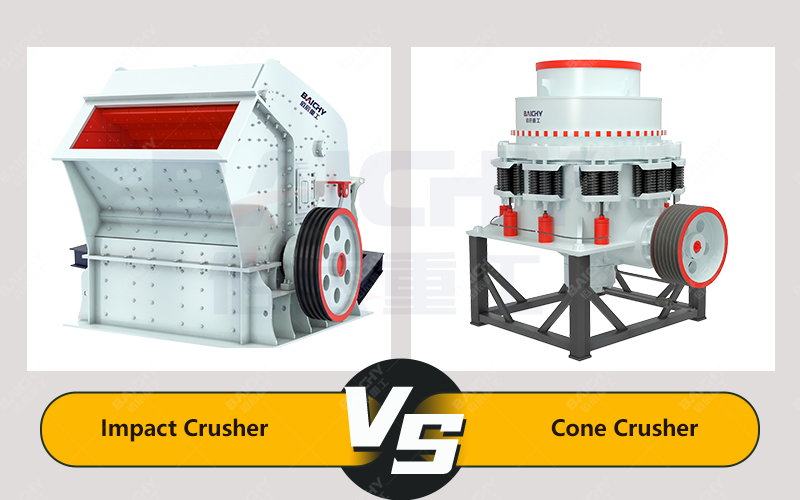

In industries such as mining, construction waste treatment, and road construction, crushing equipment plays a vital role. Among them, impact crusher and cone crusher are two common crushing equipment, each with unique advantages and application scenarios. So, what is the difference between them? Next, we will analyze it in detail for you.

Comparison of working principles

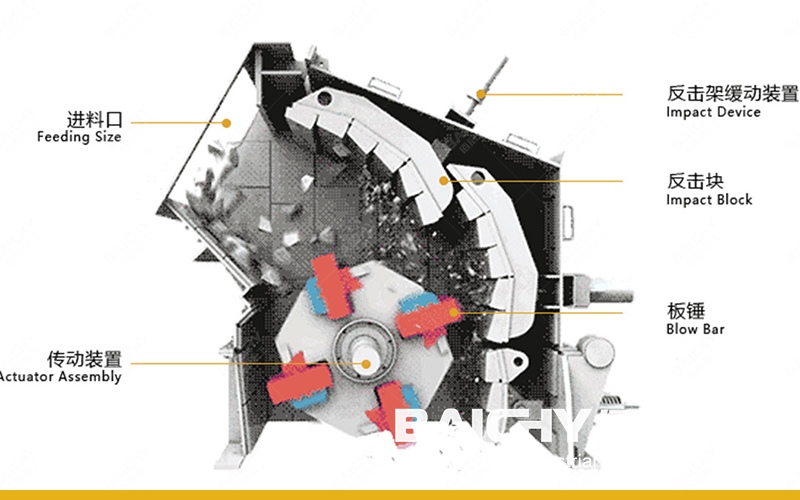

1. Impact crusher: The material is impacted and crushed by the striking plate on the high-speed rotating rotor, and the materials also collide with each other, so that the materials obtain higher impact energy in an instant, thereby achieving crushing. This crushing method is suitable for crushing brittle materials with medium hardness or below.

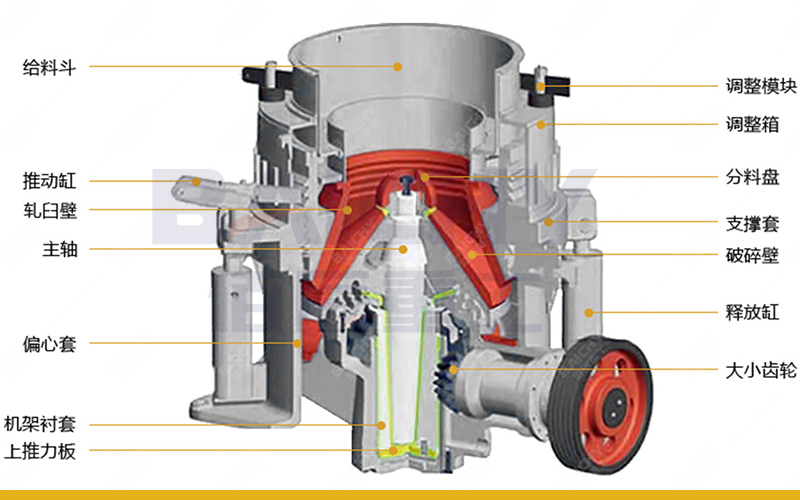

2. Cone crusher: Adopting the lamination crushing principle, through the relative rotation between the fixed cone and the moving cone, the material is squeezed, sheared, and ground multiple times in the crushing chamber, to be crushed into products of the required particle size. A cone crusher is suitable for crushing high-hardness materials, with the characteristics of high crushing efficiency and uniform product particle size.

Feed and Discharge Sizes

1. Impact Crusher: Handles medium to large feed sizes, capable of producing finer particles through secondary or tertiary crushing.

2. Cone Crusher: Suited for intermediate feed sizes, it excels in fine and ultra-fine crushing, delivering precise particle sizes.

Crushing Capacity and Output

Impact Crusher: Characterized by its high crushing efficiency and cubic-shaped products, it's ideal for applications requiring high-quality aggregates.

Cone Crusher: Known for its high productivity and consistent performance, it's the preferred choice for demanding crushing tasks.

Price of Crushers

Pricing for these grinding equipment varies depending on several factors, including capacity, material, and manufacturer. Generally speaking, Jaw Crushers tend to be more cost-effective for primary crushing applications, while Cone Crushers may command a higher price due to their precision and durability. Impact Crushers fall somewhere in between, offering a good balance between price and performance.

How to choose suitable crushing equipment?

When choosing crushing equipment, factors such as material properties, processing volume, product particle size requirements, and investment budget should be fully considered. For the crushing of brittle materials with medium hardness or below, and stone shaping in the construction field, impact crushers are a more ideal choice; while for the crushing of high-hardness materials and coarse and medium crushing operations in large mines and mineral processing plants, cone crushers are more advantageous.

As a professional crushing equipment manufacturer, we have advanced production technology and rich industry experience and can provide customers with customized crushing equipment solutions. No matter what type of crushing equipment you need, we will serve you wholeheartedly to ensure that you get the best quality products and services.