Limestone crushing production line is a stone processing production line designed for limestone, limestone and other minerals with similar hardness.

Function: Coarse or fine crushing of limestone to achieve various particle sizes that meet production requirements, which is convenient for subsequent deep processing.

Process plan: There are usually two common plans, namely graded crushing and one-time forming, which can be selected according to specific needs.

Process flow of limestone crushing production line

1. Mining: Mining limestone raw materials from mines.

2. Coarse crushing: The large pieces of limestone after mining are evenly fed to the

jaw crusher for coarse crushing through a vibrating feeder.

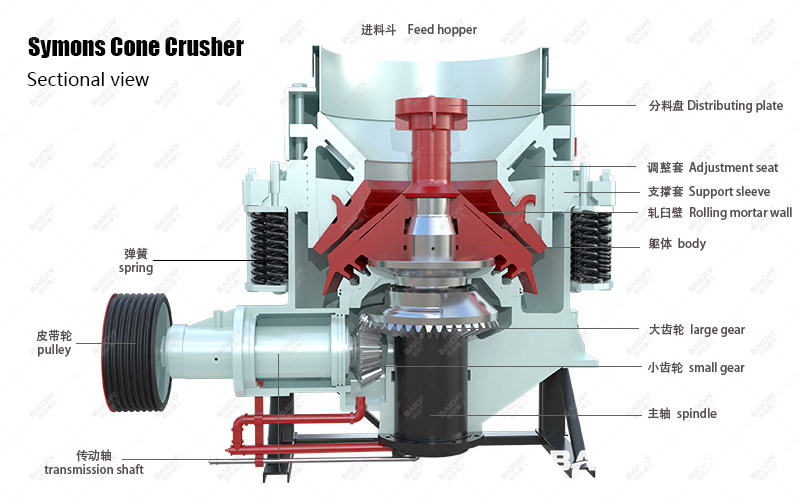

3. Medium and fine crushing: The coarsely crushed materials are transported to the impact crusher (or cone crusher) through a belt conveyor for medium and fine crushing.

4. Screening: The limestone blocks after medium and fine crushing are screened through a vibrating screen and divided into different specifications according to the particle size.

5. Finished product: The screened stone becomes a finished stone that meets production requirements and can be used in various engineering construction.

Equipment configuration of 500t/h limestone crushing production line: limestone crushing production line roller feeder GZS1500*5000, deep cavity jaw crusher PE1000X1200, three-chamber impact crusher PFW1520, three-chamber impact crusher PFW1214, circular vibrating screen 2YK2460.

According to actual production needs, auxiliary equipment such as dust removal equipment and noise reduction equipment may also need to be configured to ensure the environmental protection and safety of the production line.

Notes:

1. When configuring the production line, it is necessary to comprehensively consider factors such as the characteristics of the actual raw materials, market demand, and production site conditions to ensure the efficient and stable operation of the production line.

2. During the production process, it is necessary to regularly inspect and maintain the equipment to ensure the normal operation of the equipment and extend the service life of the equipment.

3. Environmental protection and safety issues are also factors that need to be considered in the production process, and appropriate measures need to be taken to ensure the environmental protection and safety of the production line.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.