Granite has a uniform structure, hard texture, beautiful color, and is durable. It is a high-quality building stone and is known as the "king of rocks". In construction, granite can be used from roofs to floors. If it is crushed, it can also be made into cement or rock-filling dams. Granite is not easy to weather, has beautiful colors, and its appearance can be maintained for more than a hundred years. In addition to being used as high-end building decoration and hall floors, it is also the material of choice for open-air carving. Because granite is rarer than ceramics or other man-made materials, laying granite floors can greatly increase the value of the real estate, and natural granite countertops have unique temperature resistance, making them the best choice for processing all kinds of plates.

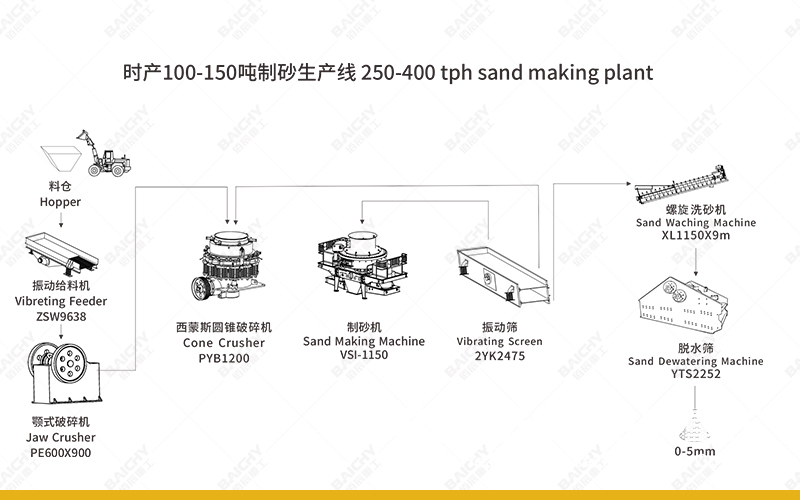

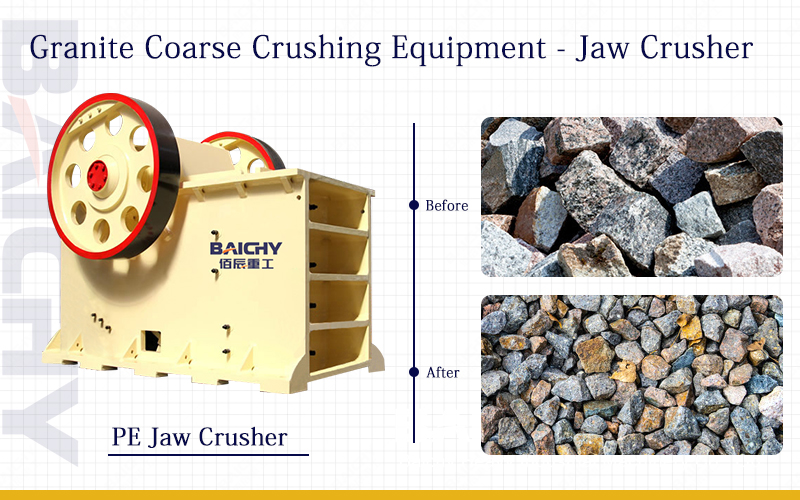

Stage 1: Coarse crushing

The second stage: medium and fine crushing

The third stage: sand making

The fourth stage: packaging

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.