Jaw crushers are widely used in mining, construction, infrastructure construction and other industries as primary and secondary crushing equipment.

The model of jaw crusher is determined by the width of the feed opening. Jaw crushers are divided into three types: large, medium and small. The feed opening width is greater than 600mm for large machines, 300-600mm for medium machines, and less than 300mm for small machines.

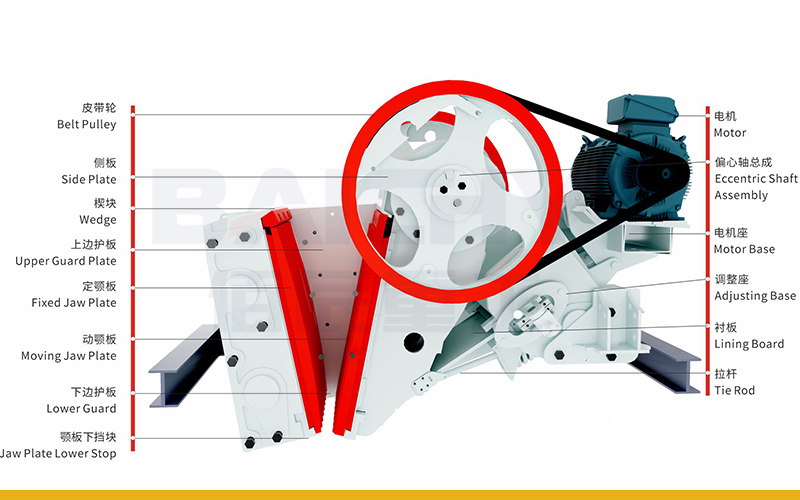

Composition of jaw plate of jaw crusher

1. The working part of the jaw crusher consists of two jaw plates, one of which is a fixed jaw plate, which is fixed vertically (or slightly tilted outward at the upper end) on the front wall of the machine body.

2. The other type is the movable jaw plate, which is inclined and forms a crushing chamber (working chamber) with a large upper part and a small lower part with the fixed jaw plate.

The movable jaw plate makes periodic reciprocating motion relative to the fixed jaw plate, sometimes separated and sometimes close. During separation, the material enters the crushing chamber and the finished product is discharged from the bottom; during approach, the material placed between the two jaw plates is compressed, bent, split, etc. to be crushed.

Working principle of movable jaw

During the process of crushing materials, the main function of the movable jaw is to form a crushing chamber inside the crusher to crush the materials. Its working principle is to control the distance between it and the fixed tooth plate to realize its complex planar motion characteristics so that the material is driven downward during the crushing process.

After tracking, observing, and calculating various types of crushers used in production practice, we found that: if the optimized design of the crusher structure is the fundamental factor to ensure the superior performance of the crusher, then a reasonable movable jaw structure is a sufficient condition to ensure the superior performance of the crusher.

Stress study of movable jaw

The movable jaw is impacted by stones in the working state, and its main stress point is the upper part of its lower toggle plate seat, which is prone to cracking. Through the analysis of the stress on the movable jaw, it can be seen that the part of the movable jaw that is subjected to greater stress is located near the cross-section of this stress point, resulting in greater stress here and easy damage. The so-called "stress" here refers to the internal force generated by the interaction of various parts when an object is deformed by external factors (such as force, humidity, temperature field changes, etc.). The internal force per unit area is called stress.

According to the above stress analysis of the crusher jaw, it can be concluded that:

1. The movable jaw generates greater stress near the toggle plate, resulting in frequent cracking and damage here;

2. When the stress values of the upper and lower parts of the movable jaw differ greatly, it is easy to reduce the service life of the movable jaw. The design of the movable jaw is extremely unreasonable, and the stress cross-section is too small or too large, which can easily cause the particle crusher to malfunction and affect production.

BAICHY Abstract

The movable jaw and the fixed jaw are indispensable parts of the jaw crusher. Together, they form the crushing chamber and complete the material crushing process. The movable jaw forms an extrusion space with the fixed jaw through reciprocating motion to crush the material, while the fixed jaw remains stationary to provide stable support for the crushing process. Both are carefully designed and optimized in terms of material and structure to ensure efficient and stable crushing effects.