There are various types and specifications of granite crushers to meet the crushing requirements of different production needs and rock characteristics. The following are several common types of granite crushers and their specifications:

1. Granite jaw crusher

Jaw crusher is often used as the primary crushing equipment for crushing granite. It has a large crushing ratio and can crush granite of about 500mm to less than 100mm at a time. It has a high production capacity, for example, some models can reach 2200 tons/hour. The discharge particle size is uniform and the discharge port is easy to adjust.

2. Granite cone crusher

Cone crushers are divided into three types: spring type, hydraulic type and compound type. It is mainly developed for medium and fine crushing equipment of high-hardness materials.

Commonly used for medium and fine crushing of granite. Cone crushers have single-cylinder, multi-cylinder, fully hydraulic, and other cavity types to meet different production needs. Layered crushing principle, high crushing efficiency, and good particle shape.

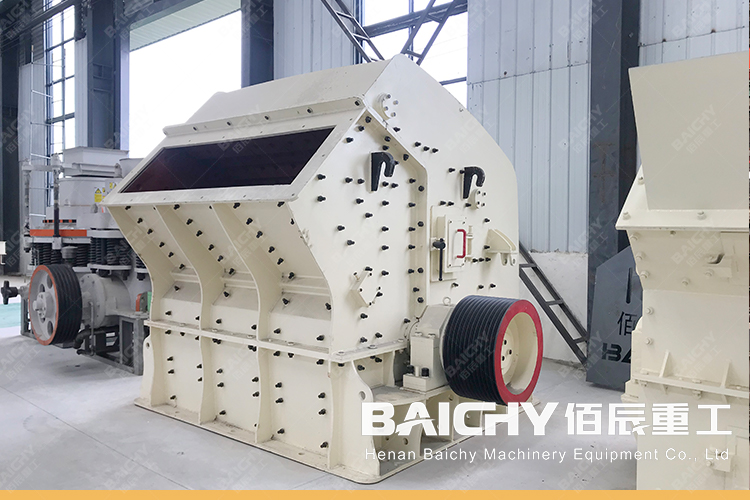

3. Granite impact crusher

The impact crusher can continuously impact, shear, bump and other effects on large pieces of granite ore and crush them. The crushed particles are in good shape. Processing materials with a side length of less than 100-500 mm, and the output particle size ≤40mm accounts for 90%.

4. Granite Roller Crusher

Granite roller sand-making machines can be divided into large roller crushers and small roller crushers according to the output and model size.

Large roller crusher models are: 2PG1200×800, 2PG1500×800, 2PG1600×1000, etc., small roller crusher models are: 2PG400×250, 2PG400×400, 2PG610×400, etc.

These granite crushers have different characteristics and specifications, suitable for different production scenarios and needs. When choosing, it is necessary to comprehensively consider factors such as the specific granite hardness, particle size, output requirements, and budget. At the same time, in order to ensure the efficient operation of the crusher and extend its service life, regular maintenance and maintenance are also very important.