As an important industrial raw material, gypsum powder is widely used in construction, medical treatment, art and other fields. Choosing the right grinding equipment is crucial to the production quality, efficiency and cost control of gypsum powder. This article will give you a detailed introduction to the characteristics, applicable scenarios and purchase recommendations of various types of gypsum powder grinding equipment.

1. Detailed explanation of common gypsum powder grinding equipment

1.1 Raymond mill (recommended first choice)

Core advantages:

• The finished product fineness is adjustable from 80 to 325 mesh, meeting most application requirements

• Low unit energy consumption, more than 30% energy saving compared to traditional equipment

• Adopts three-dimensional structure design, small footprint

• The transmission device adopts a closed gear box, which runs smoothly and reliably

Applicable scenarios:

• Small and medium-sized gypsum powder processing plants (daily output 5-100 tons)

• Gypsum powder production for construction

• Preliminary processing of medical-grade gypsum powder

1.2 Ball mill (special for ultrafine powder)

Technical features:

• Rolling bearings are used instead of sliding bearings to reduce friction by 30%

• Equipped with a grading system, it can produce 600-3000 mesh ultrafine powder

• The cylinder adopts wear-resistant lining, with a service life of more than 5 years

• Noise control below 75 decibels

Typical applications:

• High-end medical gypsum powder

• Gypsum powder for precision casting

• Preparation of special ceramic raw materials

1.3 Vertical grinding mill (preferred for large production lines)

Performance advantages:

• The output of a single machine can reach more than 50 tons per hour

• Energy consumption is 30-40% lower than that of Raymond mill

I• ntegrates crushing, grinding and grading

• Fully enclosed system, less dust pollution

Investment advice:

Suitable for enterprises with sufficient fixed asset investment budget

Modern factories with high automation requirements

Regions with strict environmental protection requirements

2. Guide to selecting supporting equipment

2.1 Pretreatment equipment

• Jaw crusher: used for primary crushing of large gypsum ore

• Hammer crusher: medium crushing equipment, discharge particle size <30mm

• Drying system: for high moisture raw materials (optional)

2.2 Auxiliary system

• Pulse dust collector: meets environmental emission standards

• Automatic packaging machine: improves packaging efficiency

• DCS control system: realizes automated production

3. Five golden rules for equipment selection

✔ Output matching principle

• Small plant (<20 tons/day): choose Raymond mill

• Medium-sized plant (20-100 tons): vertical mill + Raymond mill combination

• Large-scale plants (>100 tons): vertical grinding production line

✔ Principle of fineness priority

• General construction powder: within 325 mesh

• Medical/food grade: above 600 mesh

• Nano-level application: classification system is required

✔ Energy efficiency evaluation method

• Compare power consumption per ton of powder

• Investigate the no-load power of the equipment

• Understand the replacement cycle of wear-resistant parts

✔ Maintenance cost calculation

• Annual replacement cost of wearing parts

• Lubrication system maintenance requirements

• Maintenance convenience evaluation

✔ Environmental compliance points

• Dust emission concentration <30mg/m³

• Noise control <85dB

• Wastewater treatment plan

4. See the question and answer

Q: What equipment can I buy with a budget of 50,000 yuan?

A: You can consider a small Raymond mill (4R3216 model), which is suitable for start-ups, with a daily output of 5-8 tons. It is recommended to use second-hand pretreatment equipment.

Q: What should I pay attention to when installing the equipment?

A: Key points:

The foundation load-bearing capacity must reach 3 times the weight of the equipment

Reserve maintenance space (1.5 meters on each side)

The power configuration must meet the peak load

Q: How to judge whether the equipment manufacturer is reliable?

A: Check:

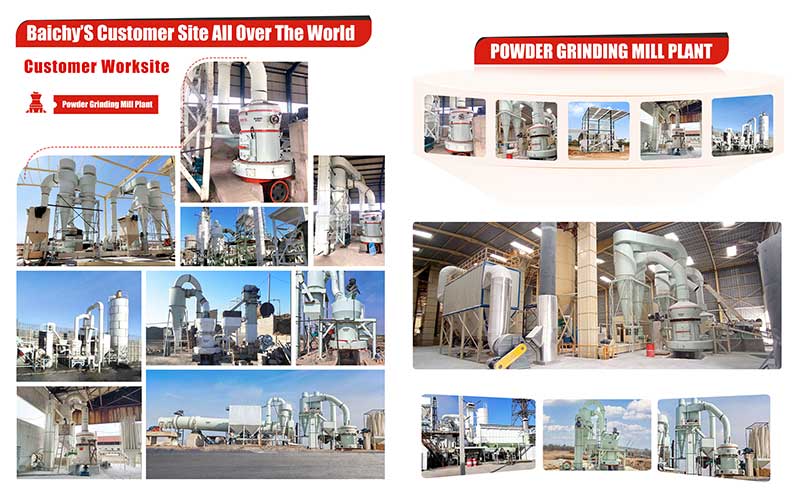

✓ On-site inspection of the production workshop

✓ Request to provide customer cases of the same model

✓ Test equipment test data

✓ Confirm after-sales response time

It is recommended that investors clarify their own product positioning and market direction before choosing equipment, and entrust professional institutions to do process design when necessary. Keeping the equipment moderately forward-looking and reserving space for future upgrades is the key to reducing long-term costs.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)