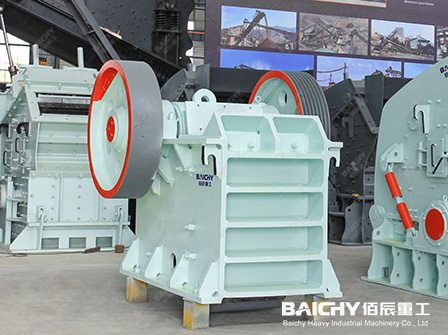

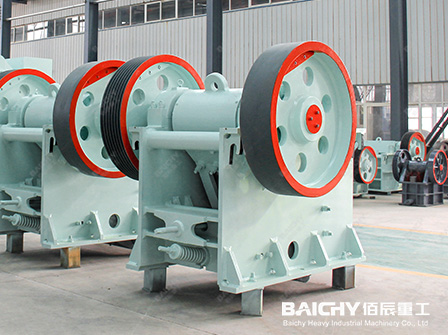

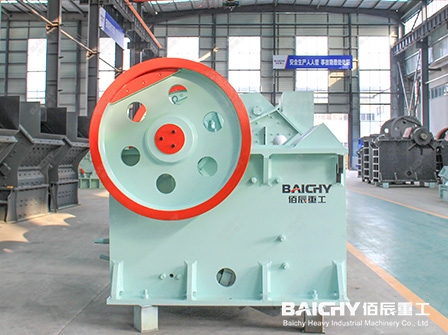

PE600x900 jaw crusher working site and application

Processing materials: such as granite, etc.

Production capacity: up to 100t/h or higher.

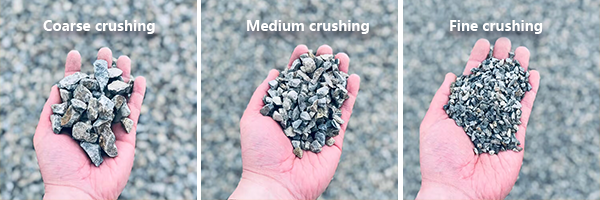

Finished product specifications: such as 51 stone, 12 stone, 13 stone, etc.

Configuration equipment: usually used in conjunction with feeders, cone crushers, vibrating screens, conveyors and other equipment.

Production line advantages: closed plant, crusher sunken installation, low noise and less dust, green production process, while ensuring production efficiency.