Gold ore ball mill (wet ball mill) is a mining equipment used to grind gold ore, which plays a key role in gold mining and processing. Through reasonable selection and use, it can effectively improve the mining efficiency and processing quality of gold mines, and contribute to the development of the mining industry.

Gold ore ball mill has a wide range of applications, including mineral processing, building materials, the chemical industry, ore industry, ferrous and non-ferrous metal mineral processing, glass and ceramics, and other production industries. In addition, most of this equipment adopts energy-saving control systems, with special automatic speed adjustment and power-saving functions, and has significant power-saving effects.

Stone crusher is used for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate, etc. Different final output sizes could meet your different needs.

Mining ball mills can adapt to different types of ores and materials. Whether they are high or low-hardness ores, they can be effectively ground.

Mining ball mills have large processing capacity and high grinding efficiency, which can greatly increase the processing speed and output of ore and meet the needs of large-scale production.

Compared with other types of grinding equipment, the energy consumption of mining ball mills is relatively low. Its optimized design and efficient working methods result in higher energy utilization, thereby reducing production costs.

Through the interaction between the grinding medium and the ore, the mining ball mill can achieve uniform grinding of the ore and obtain products with uniform particle size distribution, which is beneficial to subsequent processing and utilization.

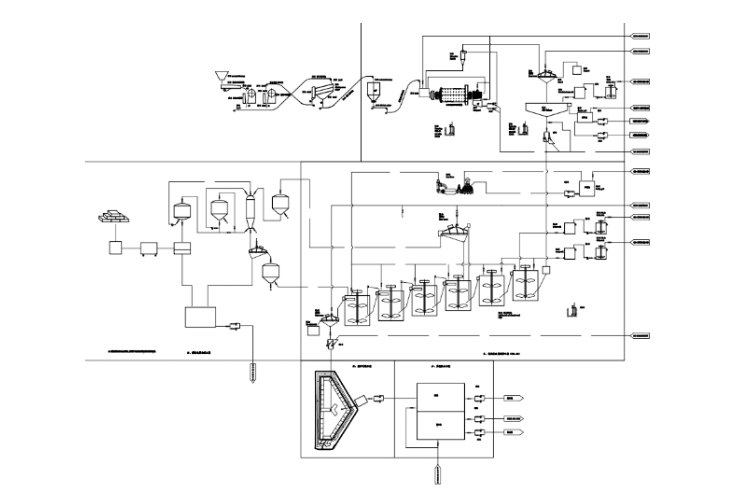

The process flow of ball mill mineral processing mainly includes the following steps:

1. Crushing: The original ore is broken into ore particles of a certain size through the crushing equipment to facilitate processing by the ball mill.

2. Ore grinding: Put the crushed ore particles into the ball mill, start the ball mill, and through rotation and friction, the ore particles will continue to collide, wear, and break, and finally be refined into particles of a certain size.

3. Classification: The ore particles processed by the ball mill usually contain particles of different sizes. For further purification, the particles need to be classified. Commonly used classification equipment includes screening machines, spiral classifiers, etc.

4. Flotation: The ground mineral slurry is flotated and refined several times to separate useful minerals and waste rocks to achieve the purpose of beneficiation.

The ball mill mineral processing process may also include other links, such as slurry preparation (mixing ore powder and water to form slurry), as well as regrinding, beneficiation, and other links that may be set up according to specific ore characteristics and mineral processing needs.

| Model | Cylinder Rotating Speed (r/min) |

Ball weight (t) |

Feeding Size (mm) |

Discharging Size (mm) |

Capacity (t/h) |

Power (kw) |

| Ф900×1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 |

| Ф900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 |

| Ф1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 |

| Ф1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 |

| Ф1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 |

| Ф1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 |

| Ф1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 |

| Ф1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 |

| Ф1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 |

| Ф1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 |

| Ф1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 |

| Ф1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 |

| Ф2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 155 |

| Ф2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 |

| Ф2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 12-48 | 280 |

| Ф2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 |

| Ф2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 |

| Ф2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 |

| Ф2200×7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 |

| Ф2400×3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 |

| Ф2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 |

| Ф2700×4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 22-80 | 380 |

| Ф2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 26-90 | 480 |

| Ф3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | TBC | 630 |

| Ф3600×4500 | 17 | 90 | ≤25 | 0.074-0.4 | TBC | 850 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery