Compared with jaw crushers, the spring cone crusher has the advantage of low operation costs, high productivity, easy adjustment, and stable structure. Cone Crusher can be used for secondary and fine crushing of hard and medium-hard mineral stones.

The moving cone rotates continuously so that the crushing process and discharging processes of materials are alternately and continuously carried out along the working surface, thereby improving productivity and crushing efficiency.

The movable cone and the fixed cone are both upright. When the movable cone swings, there is a parallel belt with equal gaps between the movable cone and the fixed cone near the discharge port of the crushing chamber, making the finished product uniform in size.

The main shaft of the crusher does not move and the eccentric sleeve transmits the crushing force. Therefore, the structure can withstand large crushing forces and is especially suitable for fine crushing and ultra-fine crushing.

The spring cone crusher has low noise and dust emissions during the crushing process, which meets environmental protection requirements.

Spring cone crusher is suitable for crushing hard and medium-hard ores and rocks, such as iron ore, copper ore, limestone, quartz, granite, basalt, diabase, etc. It is widely used in the metallurgical industry, construction industry, road construction industry, Chemical industry and phosphate industry.

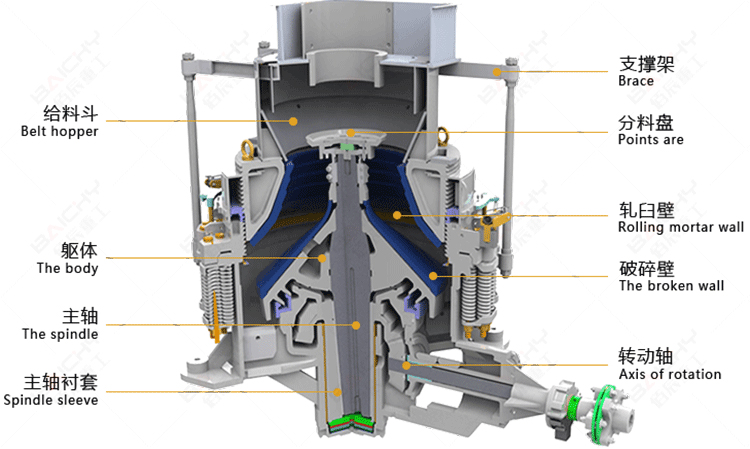

The working principle of the spring cone crusher is mainly based on its special structure and movement mode:

1. Drive and transmission: The spring cone crusher is driven by an electric motor, which transmits power to the horizontal shaft through transmission devices such as triangle belts and pulleys. The horizontal shaft then passes through the bevel gear and transmits the rotational motion to the eccentric sleeve.

2. Rotation of the eccentric sleeve: When the eccentric sleeve rotates on the horizontal axis, due to its eccentric design, the moving cone connected to it will perform a swing motion. This pendulum motion is the key to crushing materials.

3. Relative motion of the moving cone and the fixed cone: The moving cone is supported on a spherical bearing and fixed on a suspended vertical shaft. This vertical shaft is installed in an eccentric sleeve, which is located on the thrust bearing. When the eccentric sleeve rotates, the moving cone will perform a pendulum motion around its suspension point on the spherical bearing. At this time, the movable cone will sometimes approach and sometimes move away from the fixed cone, causing extrusion and impact on the material.

4. Crushing of materials: After the materials enter the crushing cavity from the feed port, they are crushed under the extrusion and impact between the movable cone and the fixed cone. With the swing motion of the moving cone, the material is squeezed and impacted multiple times in the crushing cavity and is finally broken into the required particle size.

5. The function of the spring: The casing is composed of upper and lower parts, connected by bolts. There is a strong spring on the bolt. When metal or other hard objects fall into the crushing chamber, the springs can protect the crusher from damage. If a metal block or other hard object enters the crushing chamber together with the ore, the immovable cone is lifted and the ore discharge port is enlarged to allow it to be discharged.

| Model |

Cone Dia. (mm) |

Max. Feed Size (mm) |

Adjusting Range of Output Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

| PYB-600 | 600 | 65 | 12-25 | 15-25 | 30 | 2800×1300×1700 |

| PYD-600 | 600 | 35 | 3-15 | 5-23 | 30 | 2800×1300×1700 |

| PYB-900 | 900 | 115 | 15-50 | 50-90 | 55 | 3050×1640×2350 |

| PYZ-900 | 900 | 60 | 5-20 | 20-65 | 55 | |

| PYD-900 | 900 | 40 | 3-13 | 15-50 | 55 | |

| PYB-1200 | 1200 | 145 | 20-50 | 110-200 | 110 | 4152×2300×2980 |

| PYZ-1200 | 1200 | 100 | 8-25 | 50-150 | 110 | |

| PYD-1200 | 1200 | 50 | 3-15 | 18-105 | 110 | |

| PYB-1750 | 1750 | 215 | 25-60 | 280-480 | 160 | 4870×3800×4192 |

| PYZ-1750 | 1750 | 185 | 10-30 | 115-320 | 160 | |

| PYD-1750 | 1750 | 85 | 5-15 | 75-230 | 160 | |

| PYB-2200 | 2200 | 300 | 30-60 | 590-1000 | 280 | 7705×3430×4852 |

| PYZ-2200 | 2200 | 230 | 10-30 | 200-580 | 280 | |

| PYD-2200 | 2200 | 100 | 5-15 | 120-340 | 280 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery