Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

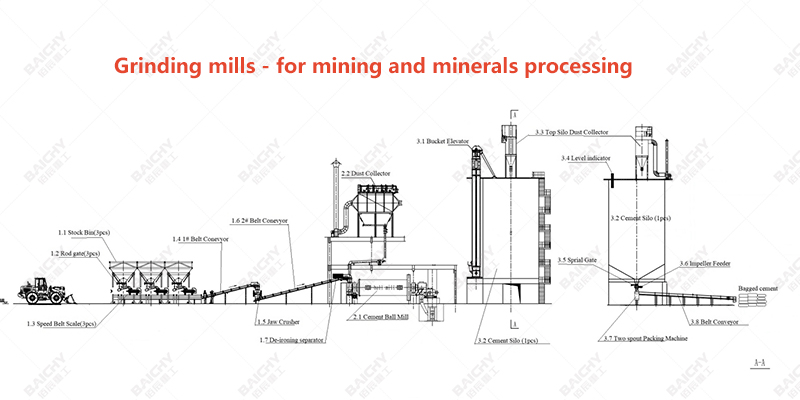

1830x4500 ball mill is a large-scale, efficient grinding equipment. Its size means that the diameter of the cylinder is 1830mm and the length is 4500mm. This equipment is mainly used for grinding ore materials in the beneficiation of metal ores and non-metallic ores.

1830x4500 ball mill rotates the cylinder to make the steel ball medium and the material collide and grind each other under the action of friction and centrifugal force, thereby achieving material crushing and grinding. The material first enters the ball mill through the feeding device, and after coarse grinding, it enters the next bin for fine grinding and is finally discharged through the unloading device.

Ball mill cylinder

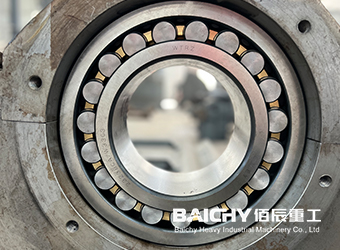

Ball mill bearing

Ball mill liner

Grinding media steel balls

| Model | Ф1830×4500 |

|---|---|

| Cylinder Rotating Speed (r/min) | 25.4 |

| Ball weight(t) | 15 |

| Feeding Size(mm) | ≤25 |

| Discharging Size(mm) | 0.074-0.4 |

| Capacity(t/h) | 4.5-12 |

| Power(kw) | 155 |

The 1830x4500 ball mill can choose between a dry ball mill and a wet grid ball mill according to the material and ore discharge method. When purchasing, you need to consider factors such as the liner material and grinding media of the ball mill to improve production efficiency and reduce costs.

1. High efficiency and energy saving: It adopts self-aligning double-row radial spherical roller bearings, which have low operating resistance and significant energy-saving effects.

2. Fast ore discharge speed: The ore discharge speed is faster and more energy-saving. It is about 30% higher than other ball mills and saves about 20% of electricity.

3. Strong adaptability to materials: simple and solid structure, reliable operation, simple maintenance and management, long-term continuous operation, strong adaptability to materials, large crushing ratio (up to more than 300), and large production capacity.

4. Good grinding effect: the material has a uniform particle shape and fine fineness, which is convenient for later processing of mineral processing.

Have Any Questions!