Dolomite grinding equipment is an important tool for processing dolomite raw materials into fine powder.

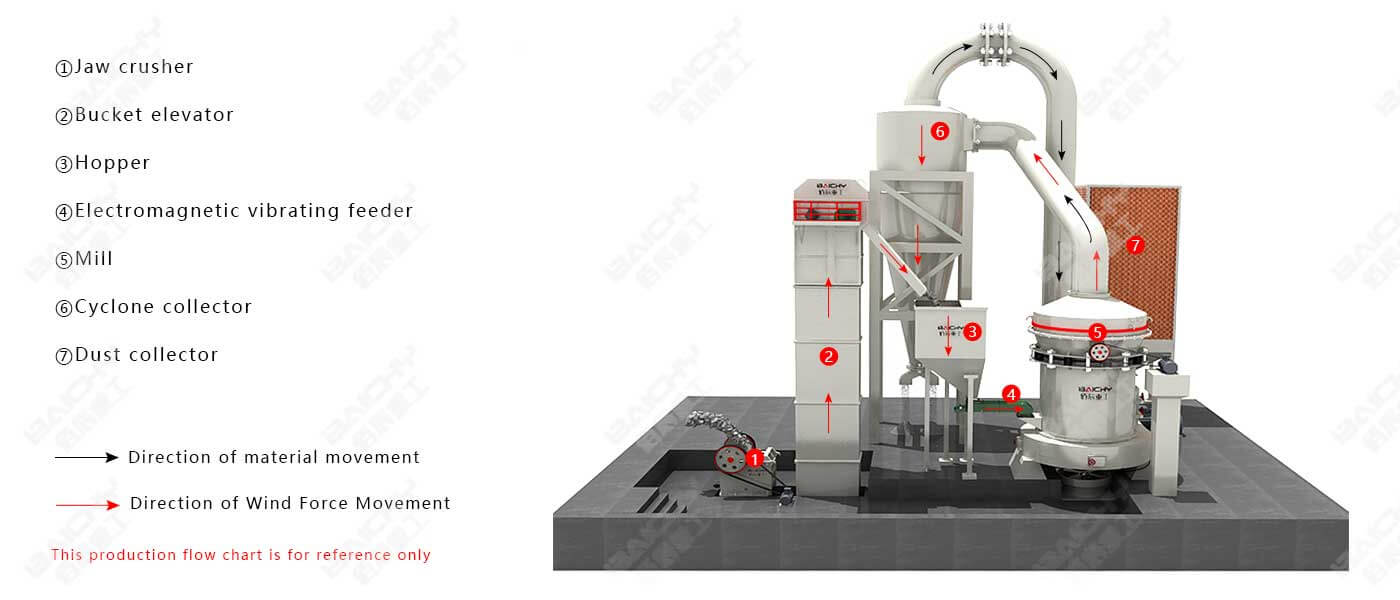

1. Crushing equipment: mainly including jaw crusher, impact crusher and cone crusher. These equipment are selected based on the physical properties of the dolomite as well as production requirements.

2. Grinding equipment:

Raymond mill: suitable for small and medium-scale production, the particle size of the finished product is adjustable. The characteristics of the equipment include large output, high efficiency and energy saving, high classification efficiency, high precision, stable and reliable operation, good shock absorption effect, long life, green and environmental protection, convenient maintenance and low cost.

Vertical roller mill: suitable for large-scale production. The equipment features include high grinding efficiency, stable product quality, low noise and environmental protection, high reliability, high degree of automation, strong drying capacity and low overall investment cost.

Ultra-fine vertical mill and ultra-fine ring roller mill: suitable for production scenarios that require finer granularity. These equipment have the characteristics of high grinding and powder selection efficiency, high production and energy saving, low operation and maintenance costs, low noise and environmental protection, high degree of automation, stable product quality and high reliability.

3. Factors to consider in equipment selection:

There are several factors to consider when choosing dolomite grinding equipment. First, the production scale and output requirements need to be clarified to determine the model and specifications of the required equipment. Secondly, the physical properties of the raw materials, such as hardness, particle size, etc., need to be considered to select appropriate crushing and grinding equipment.

1. The finished product has uniform particle size and high output:

After being processed by the dolomite grinding production line, the finished dolomite has a uniform particle size and can meet the particle size distribution requirements of different industries.

The production line adopts efficient grinding equipment, such as YGM grinding mill, etc., which ensures high output and can meet the needs of large-scale production.

2. The fineness of the finished product is adjustable:

The dolomite grinding production line can adjust the fineness of the finished product according to market demand to meet the requirements of different industries for dolomite powder fineness.

By adjusting the parameters and configuration of the grinding equipment, the fineness of the finished product can be easily adjusted and controlled.

3. Mature technology and stable operation:

The dolomite grinding production line adopts mature grinding technology and technology. After years of development and improvement, a relatively complete production line configuration and process flow have been formed.

The equipment operates stably and reliably, and can continuously and stably produce high-quality dolomite powder products.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery