• Magnetite ore is hard, so large jaw crushers are often used for crushing.

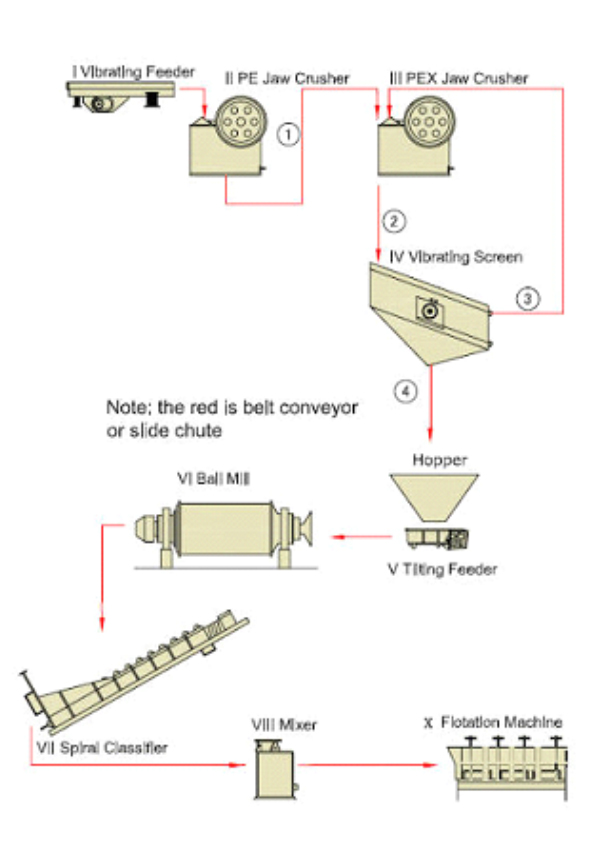

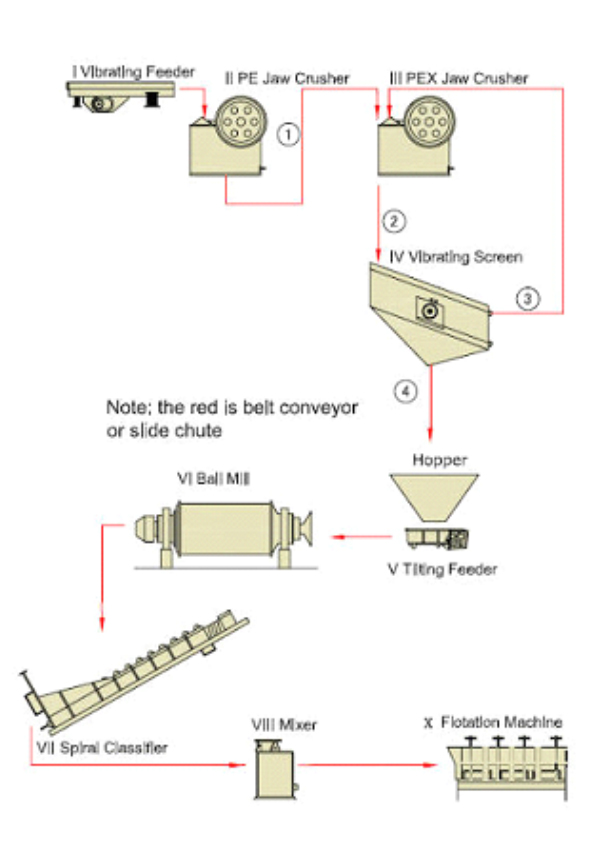

• First, the vibrating feeder evenly feeds the mined ore raw materials into the coarse jaw crusher for crushing, and then screens them into different particle sizes before fine crushing.

• The qualified materials after crushing enter the ball mill for grinding.

• The magnetite is washed and graded using a spiral classifier.

• When passing through the magnetic separator, due to the different specific magnetic susceptibility of the magnetite mineral materials, the magnetic substances in the mixture are separated to obtain fine powder.

• The concentrated iron concentrate slurry is fed into the mixing barrel, and then the slurry is fed into the filter through the underflow pump for filtration.

• After filtration, filter cake and filter filtrate are formed, and the filter cake is the dry magnetite concentrate.