Baichy Heavy Industry recommends the following solutions for your requirement of crushing equipment that can process 100 tons of materials per hour, produce 4 types of aggregates (maximum size 31 mm) and be used in roads, bridges and other projects:

1. Recommended crushing equipment combination

Coarse crushing stage: jaw crusher

Function: Process large pieces of raw materials (such as 700-900mm feed) and initially crush them to medium particle size.

Recommended model: C6X series jaw crusher. This equipment is suitable for hard materials (such as bluestone, basalt), with strong processing capacity and large feed opening, which can meet the coarse crushing needs of construction waste or ore.

Medium/fine crushing stage: impact crusher or cone crusher

Function: Further crush the coarsely crushed materials to smaller particle size for subsequent classification.

Recommended model of medium/fine crushing equipment:

PFW series impact crusher: suitable for medium hardness materials, high crushing ratio and uniform discharge particle size.

CS series cone crusher: suitable for high-hardness rocks (such as granite and quartz), low energy consumption and strong wear resistance.

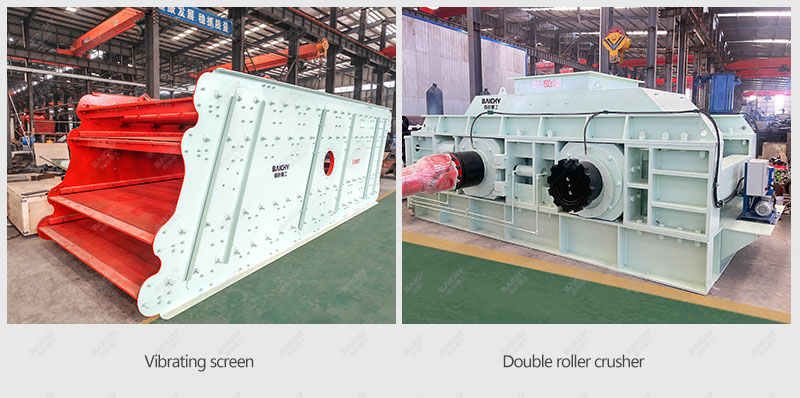

2. Screening and shaping stage: roller crusher + vibrating screen

Function: particle size control and shaping of materials after medium crushing to ensure the output of 4 types of aggregates (such as 0-5mm, 5-10mm, 10-20mm, 20-31mm).

Recommended equipment for screening and shaping:

2PGY1200×1000 roller crusher: processing capacity 100-120 tons/hour, the discharge particle size can be controlled within the range of 1-30mm by adjusting the roller spacing, suitable for fine crushing and shaping.

YK series vibrating screen: multi-layer screen design, which can efficiently separate aggregates of different particle sizes.

3. Mobile Crushing Plant

Applicable scenarios: If the work site needs to be frequently transferred (such as construction waste treatment), the K3 series tire mobile crusher is recommended, which integrates jaw crusher, impact crusher and screening equipment in one, supporting rapid deployment and closed-loop production.

Advantages of Baichy solution

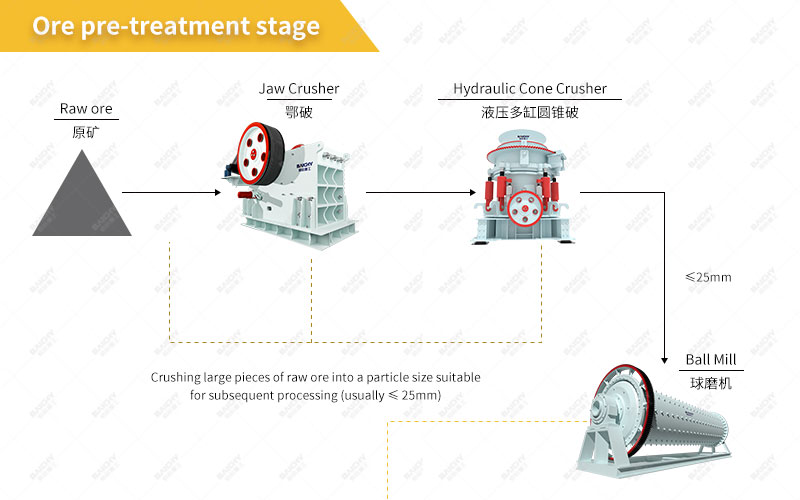

• Efficient multi-stage crushing: The process of jaw crusher coarse crushing → impact crusher/cone crusher medium crushing → roller crusher fine crushing ensures that the material is refined step by step to reach the target particle size.

• Flexible adjustment of discharge: The roller crusher can adjust the roller spacing through the hydraulic system to accurately control the discharge size (1-30mm); the vibrating screen supports multi-layer screen configuration to achieve synchronous output of aggregates of multiple specifications.

• Environmental protection and energy saving: The equipment is equipped with a dust removal system and a low-noise design to meet the environmental protection requirements of the project; hydraulic drive technology reduces energy consumption.

• Economic efficiency: The fixed production line has a low cost and is suitable for long-term stable operation; the mobile production line saves infrastructure costs and is suitable for temporary or decentralized projects.