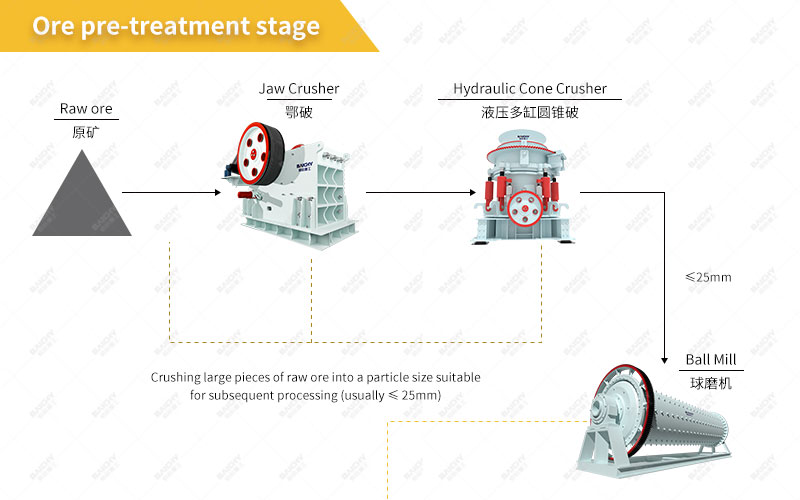

The jaw crusher is a key piece of equipment in the production line. Its function is to break the large copper ore into smaller particles for subsequent grinding.

The ball mill is another core equipment, which will further grind the broken copper ore into powder.

The output size 100 mesh is a unit that represents the fineness of the powder. The larger the mesh number, the finer the powder.

The basic working principle is that the jaw crusher crushes the copper ore into smaller particles. Then, these particles enter the ball mill and are further ground into powder. Finally, the fineness of these powders reaches 100 mesh and is output as the product.

Jaw crushers usually have a "V"-shaped deep-cavity crushing structure with no dead zone, making it difficult for materials to get stuck in the crushing chamber. The internal design of the crusher is reasonable, which can effectively improve the production efficiency of the equipment and meet the needs of large-scale production.

Jaw crushers are made of advanced manufacturing processes and highly wear-resistant materials, such as high manganese steel and alloy steel so that key components such as the movable jaw and the static jaw have good compression and wear resistance. This helps to extend the service life of the equipment, reduce downtime for maintenance, and improve overall production efficiency.

Ball mills can achieve efficient and uniform grinding by optimizing the shape, size and ratio of the grinding media, as well as adjusting the speed and filling rate of the barrel. This efficient grinding capability not only improves product quality, but also significantly increases production efficiency.

Ball mills can process ores of various hardnesses, including copper ore, and can adjust grinding parameters according to the properties of the material. In addition, ball mills can be made into equipment of different sizes to meet various production capacity requirements.

Related recommendations: Wet Ball Mill