In the fields of mining, construction aggregates and road engineering, the 150-200t/h stone crushing production line has become an ideal choice for medium and large projects with its high production capacity, stability and intelligent operation. This article analyzes the core value of this production line for you from equipment configuration, core advantages to application scenarios.

150-200t/h stone crushing production line core equipment configuration

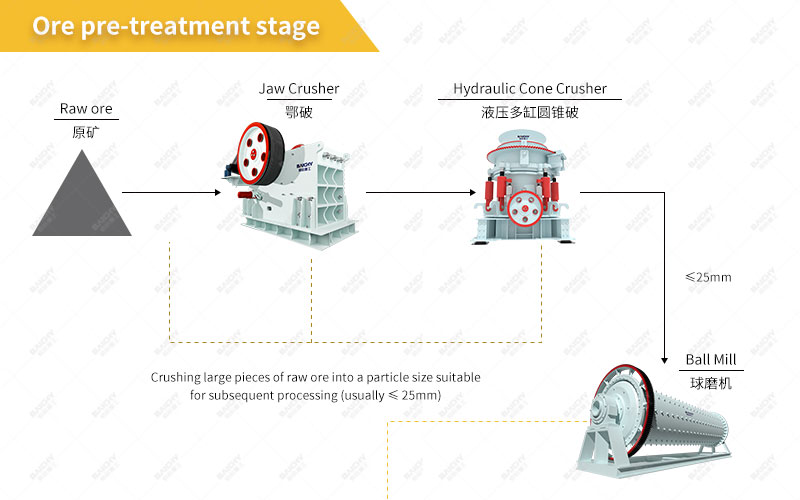

1. Coarse crushing equipment: jaw crusher (PE series)

1. Handle large pieces of raw materials (≤1200mm), high compressive strength, ensure primary crushing efficiency.

2. Medium and fine crushing equipment: impact crusher (PF series) or cone crusher (HP series)

Impact crusher is suitable for medium and low hardness stones, and the finished product has excellent particle shape; cone crusher is suitable for high hardness materials and has strong wear resistance.

3. Screening and conveying: multi-layer vibrating screen (3YK/4YK series) accurately classifies, and belt conveyor seamlessly connects to reduce material blockage.

2. Core advantages of 150-200t/h stone crushing production line

1. High efficiency and energy saving: intelligent control system (PLC/frequency conversion technology) reduces energy consumption by 15%-20%, and stable production capacity meets standards.

2. Strong adaptability: mobile or fixed solutions can be configured to flexibly deal with a variety of materials such as granite, limestone, pebbles, etc.

3. Environmental protection: closed design + pulse dust removal, dust and noise dual control, in line with environmental protection policy requirements.

4. Fast return on investment: modular design reduces maintenance costs, and cost recovery is achieved within 1-2 years.

Typical application scenarios

5. Quarry: Rapid processing of construction gravel and machine-made sand to meet the needs of commercial mixing stations and prefabricated components.

6. Solid waste recycling: crushing construction waste and concrete waste to achieve resource recycling.

7. Mining deep processing: providing high-purity raw materials for the metallurgical and chemical industries.

The 150-200t/h stone crushing production line has become the preferred solution for large-scale production with its high cost-effectiveness, intelligent operation and maintenance, and environmental protection advantages. Whether it is a new project or an old line renovation, the equipment combination can be customized according to needs to maximize the return on investment.

Consult now to get exclusive configuration solutions and quotes! WhatsApp:0086 15093222637