Is it worth investing in a stone crusher?

Market demand for stone crushing equipment

1. Infrastructure construction: Infrastructure construction is one of the main demand drivers for the stone crushing machinery market. With the acceleration of urbanization and the increase in demand for transportation construction, the demand for stone crushing machinery has also increased.

2. Real estate development: Stone crushing machinery also has important applications in the field of real estate development. The construction industry has a large demand for building materials such as sand, gravel, and crushed stone, which has driven the demand for stone crushing machinery and equipment.

3. Road construction: Road construction is one of the important uses of the stone crushing machinery market. The construction of transportation infrastructure such as highways and expressways requires a large number of crushed stone products, which has driven the demand for stone crushing machinery and equipment.

4. Mining: Mining requires a large number of stone crushing machinery and equipment for crushing, screening and other processes to produce stone products of various specifications to meet the needs of construction and infrastructure construction.

Investment cost and return of stone crushing equipment

1. Investment cost: The investment cost of a stone crusher includes the equipment purchase cost, operating cost (such as fuel, electricity, labor, etc.) and possible maintenance cost. Equipment prices vary depending on factors such as brand, model, and configuration. The price of a stone crusher on the market usually ranges from 100,000 to 1 million.

2. Return on investment: The return on investment in the stone crusher industry is usually high, but the specific return depends on multiple factors such as market demand, production efficiency, and sales price. Through reasonable business strategies and business expansion, entrepreneurs can achieve profitability in a short period of time and achieve long-term stable returns.

What factors affect the price of a stone crusher?

Equipment configuration and type

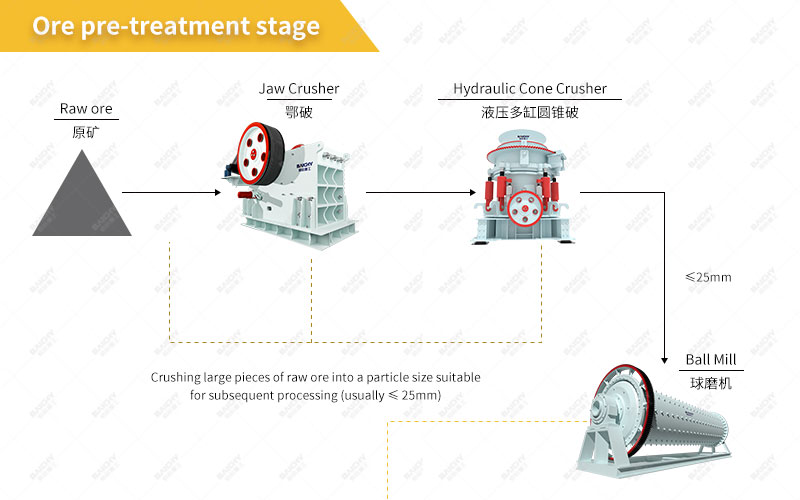

1. Core crushing system: The stone crusher consists of multiple systems, and its core crushing system can be flexibly selected, such as jaw crusher, impact crusher, cone crusher, etc. These different types of crushers have different prices, and different models of the same type have different prices. For example, the price of equipment equipped with a jaw crusher is relatively low, while the price of equipment equipped with a cone crusher may be higher.

2. Production line configuration: A set of stone crushing machinery equipment usually includes a feeder, a crusher, a sand making machine, a conveyor, a screening machine, etc. The price will also vary depending on the different configurations and production capacity requirements of the production line. For example, a 50-ton-per-hour stone crushing equipment production line has an investment cost of about 400,000 yuan, while a 200-ton-per-hour production line may cost as much as 1.59 million yuan.

1. Types of stone crushers

First, the type of stone crusher is an important factor that affects the price. There are many types of stone crushers, including jaw crushers, cone crushers, impact crushers, sand making machines, mobile crushers, and gyratory crushers. Each type of stone crusher has unique features and advantages that you can use to determine the type that best suits your specific needs.

Jaw crushers are the most common type of stone crusher. They are typically used to crush softer materials, such as limestone or gypsum, but can also be used to crush harder materials, such as granite or basalt. Jaw crushers are known for their ability to crush a wide range of materials, and they are generally the most affordable type of crusher.

Cone crushers are another type of stone crusher. They are similar to jaw crushers and can be used to crush a wide range of materials, but they are generally more powerful and capable of crushing harder materials, such as granite or basalt. Cone crushers are also known for their ability to create a more cubic shape when crushing materials.

Impact crushers are another type of rock crusher. They are usually used to crush softer materials, such as limestone or gypsum, but can also be used to crush harder materials, such as granite or basalt. Impact crushers work by using a series of hammers to crush the material, and they are known for their ability to create a more cubic shape when crushing the material.

Gyratory crushers are the last type of rock crusher. They are similar to cone crushers and can be used to crush a variety of materials, but they are usually more powerful and capable of crushing harder materials, such as granite or basalt. Gyratory crushers are known for their ability to create a more cubic shape when crushing materials, and they are usually the most expensive type of crusher.